Method for producing liquefied gas from plant stalks

A technology of liquefied gas and plant straw, which is applied in liquefaction, waste fuel, refrigeration and liquefaction, etc., can solve the problems that cannot be sold as commodities, and achieve good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The method for producing liquefied gas by using plant straws includes raw material preparation and liquefied gas preparation. The raw materials are plant straw, rice husk, rice bran, etc., and the straw is crushed and pressed into blocks.

[0042] Making liquefied gas includes the following steps:

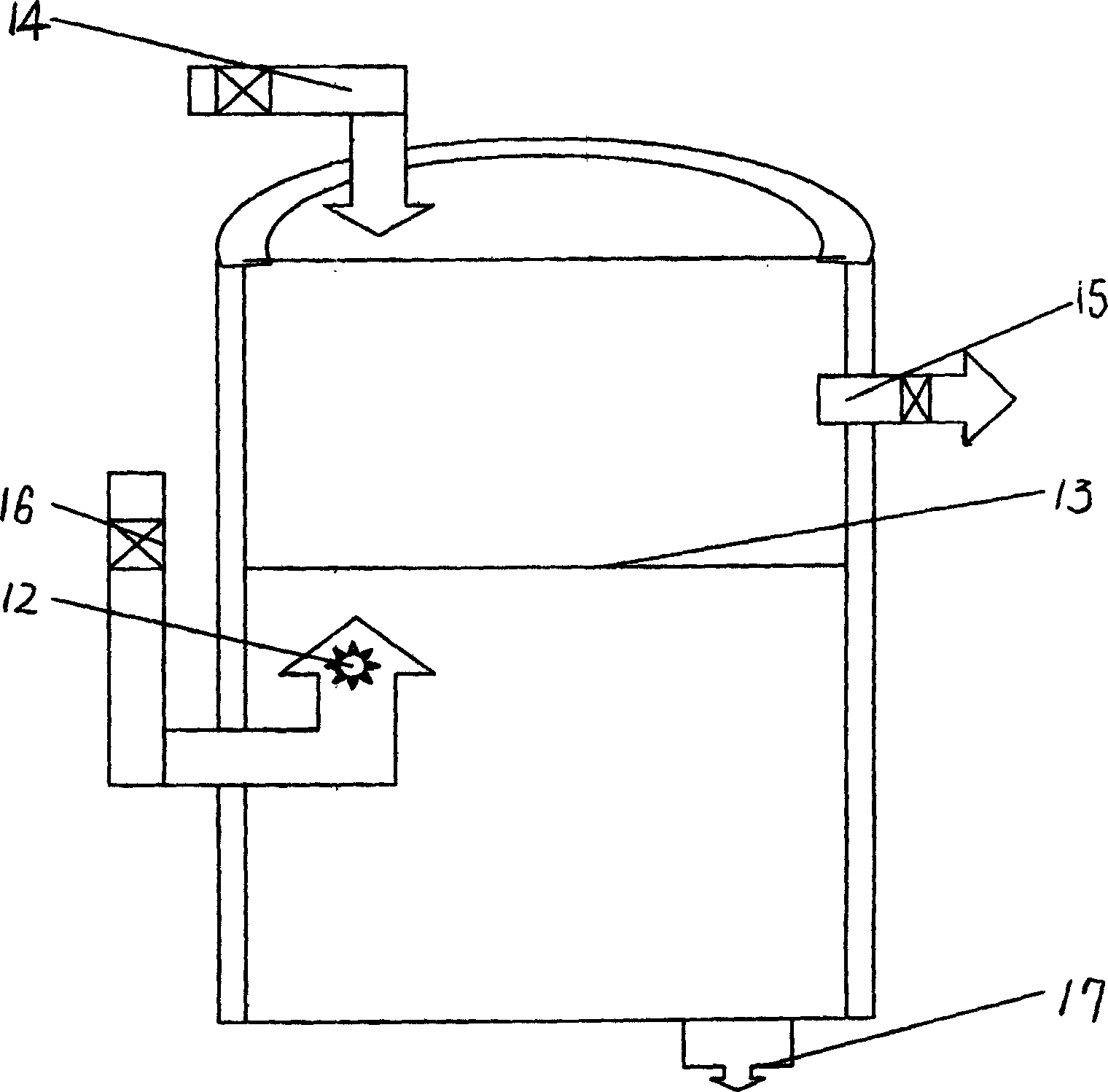

[0043] 1. Take 320kg of the prepared raw materials and put them into the gasification chamber 10 of the gasification furnace from the feed port 1 of the gasification furnace. It accounts for 70-80% of the volume of the gasification chamber 10. In order to prevent dead furnace, 4 kg of solid powdery ethanol is added to the raw material and stirred evenly. The raw materials in the gasification chamber 10 are burned under the condition of lack of oxygen, and the generated flue gas is output from the gas outlet 3 of the gasification furnace.

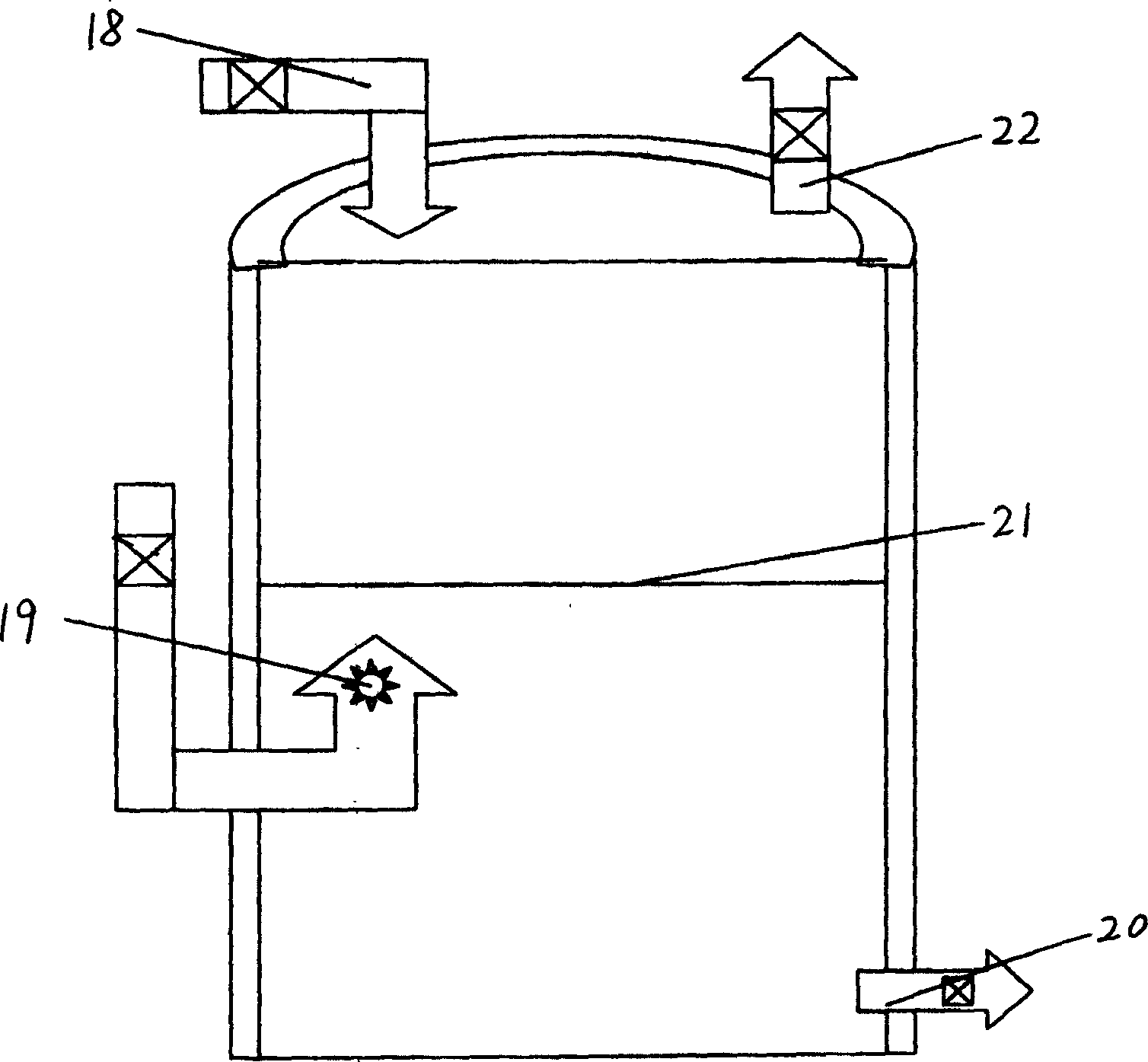

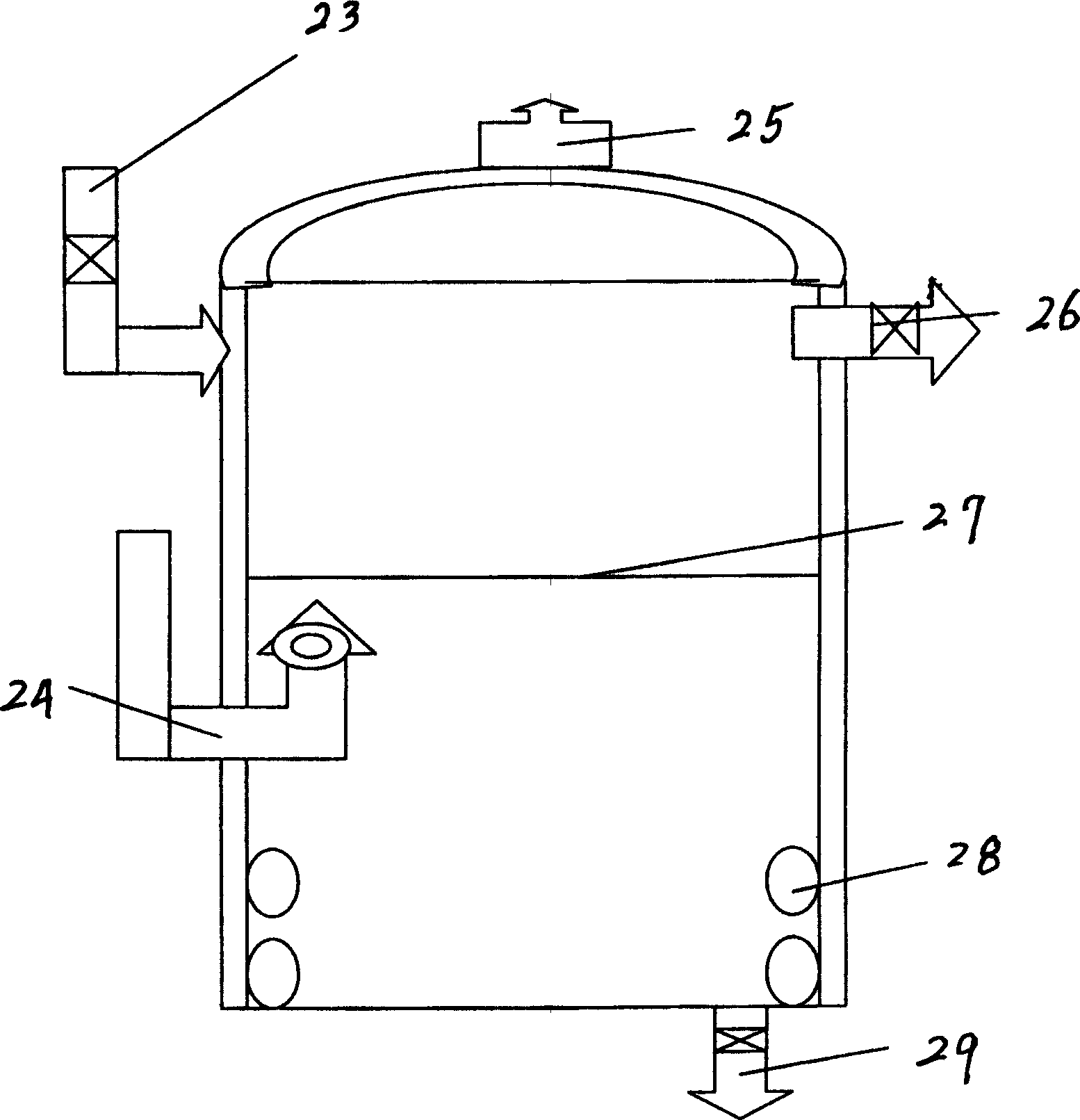

[0044] 2. Purification. The flue gas that is exported from gasification furnace gas outlet 3 enters in the purifier 1 from the air inl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com