Method for monitoring film thickness of optical filter

A technology of film thickness and optical film, applied in optical filters, special data processing applications, instruments, etc., can solve problems such as inconvenient compensation of coating errors, thickness differences, and control accuracy problems, and achieve manual control and automatic control Optimize, reduce the amount of calculation, improve the effect of control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

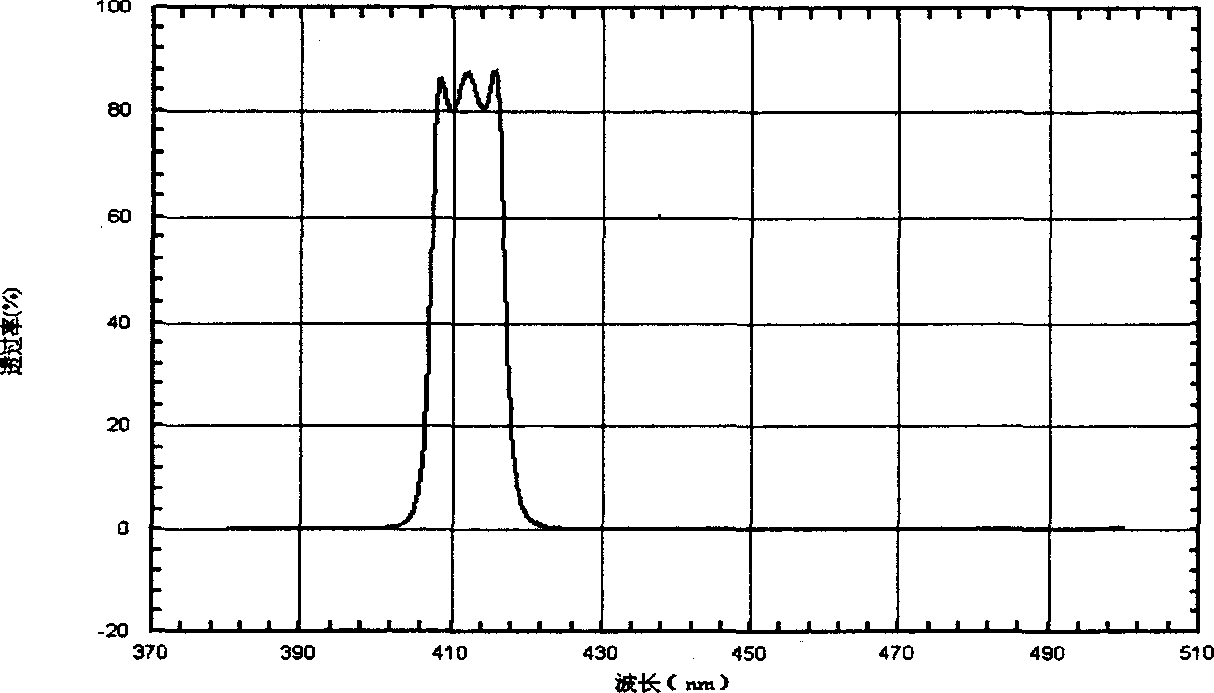

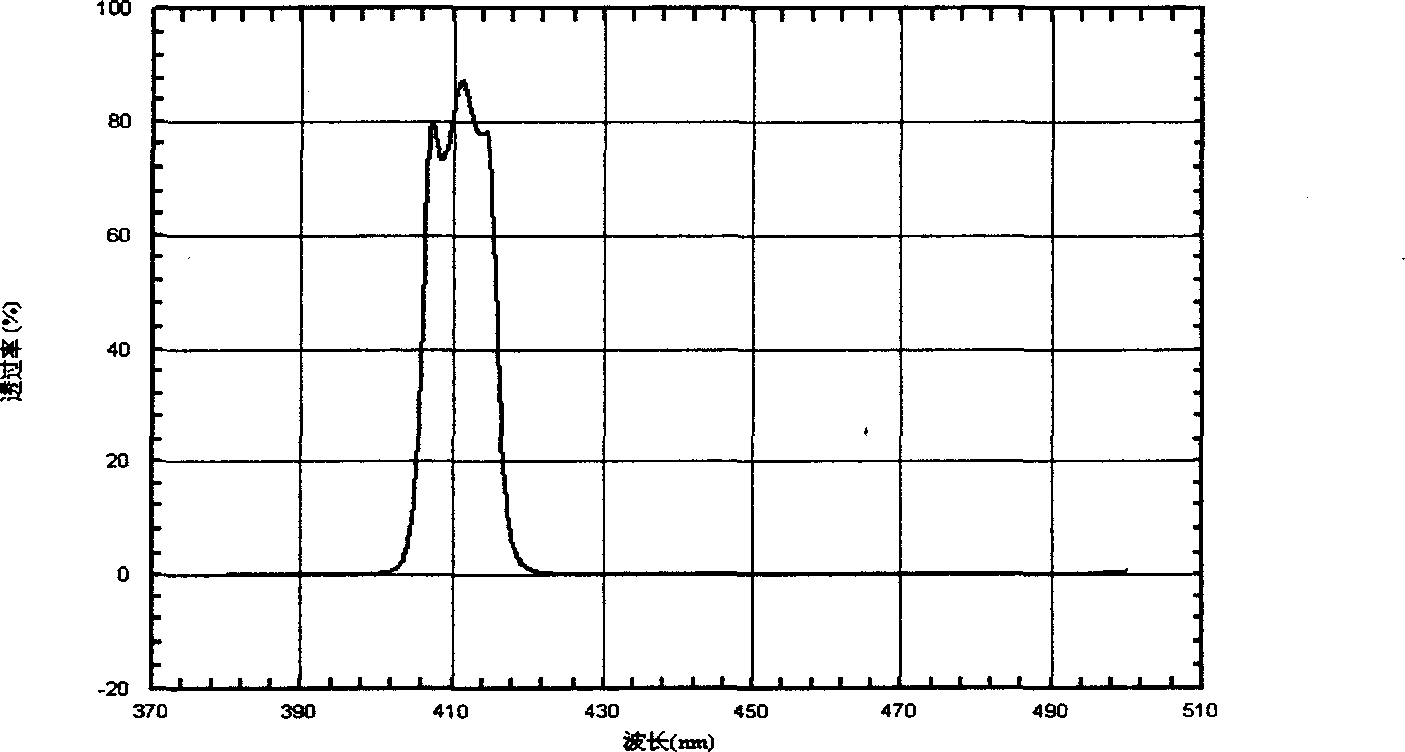

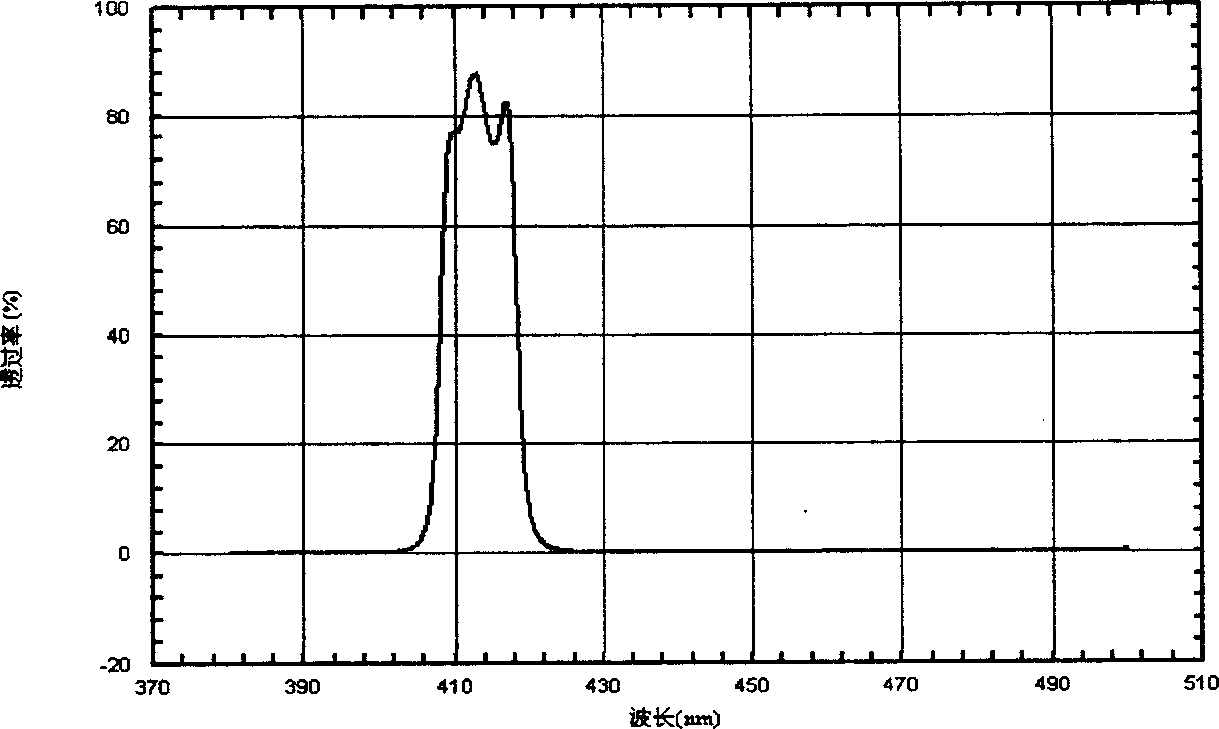

[0031] Example 1: 412nm narrow-band filter with a bandwidth of 20nm. The film system of the three-half-wave narrow-band filter is (LHLH2LHLH)3, L is SiO2, H is TiO2, and 3 monitors are selected, and the film system of each control film For LHLH2LHLH, the monitoring film adopts Si, and the indirect control method of reflective optical extreme value is used to monitor the film thickness. The preparation of the optical film of the filter is carried out according to the above steps. figure 2 It uses the optical film design Filmward software to simulate and analyze the calculated spectral curve. figure 2 The three calculation curves in the middle represent the different effects brought about by the change of the monitoring wavelength of the three monitoring chips if there is no error in the monitoring and no change in the evaporation state. figure 2 The calculation curve of (a) simulates that the monitoring wavelengths of the three monitoring chips are the same, and there is no chan...

example 2

[0032] Example 2: Infrared cut filter, its requirement is 420-600nm, transmittance is greater than 85%, λ=645nm, T=50%, 700-1050nm, T 平均 最大 <10%. The membrane system is designed as two cut-off membrane stacks, and the membrane system is: 1.214L 1.118H 1.123L.996H 1.074L.957H1.06L.963H 1.056L.96H 1.054L.966H 1.064L.972H 1.073L 1H 1.11L 1.07H 1.23L1.264H 1.355L 1.322H 1.371L 1.326H 1.362L 1.317H 1.37L 1.34H 1.389L 1.354H1.397L 1.352H 1.383L 1.315H 1.299L 1.142H.58L.

[0033] Monitoring wavelength λ 0 =735nm, L-SiO2, H-TiO2.

[0034] Therefore, six monitoring films are used, and each of the first five monitoring films is coated with 6 layers of film. The film system of the monitoring films is:

[0035] The first monitoring film: 1.214L 1.118H 1.123L.996H 1.074L.957H;

[0036] The second monitoring film: 1.06L.963H 1.056L.96H 1.054L.966H;

[0037] The third monitoring film: 1.064L.972H 1.073L 1H 1.11L 1.07H;

[0038] The fourth monitoring film: 1.23L 1.264H 1.355L 1.322H 1.371L 1.326H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com