Process for making bacteriostatic backing material with silver film

A manufacturing method and technology of silver thin film, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of inability to achieve commercial functions, inability to enjoy the quality of life of nano-silver, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

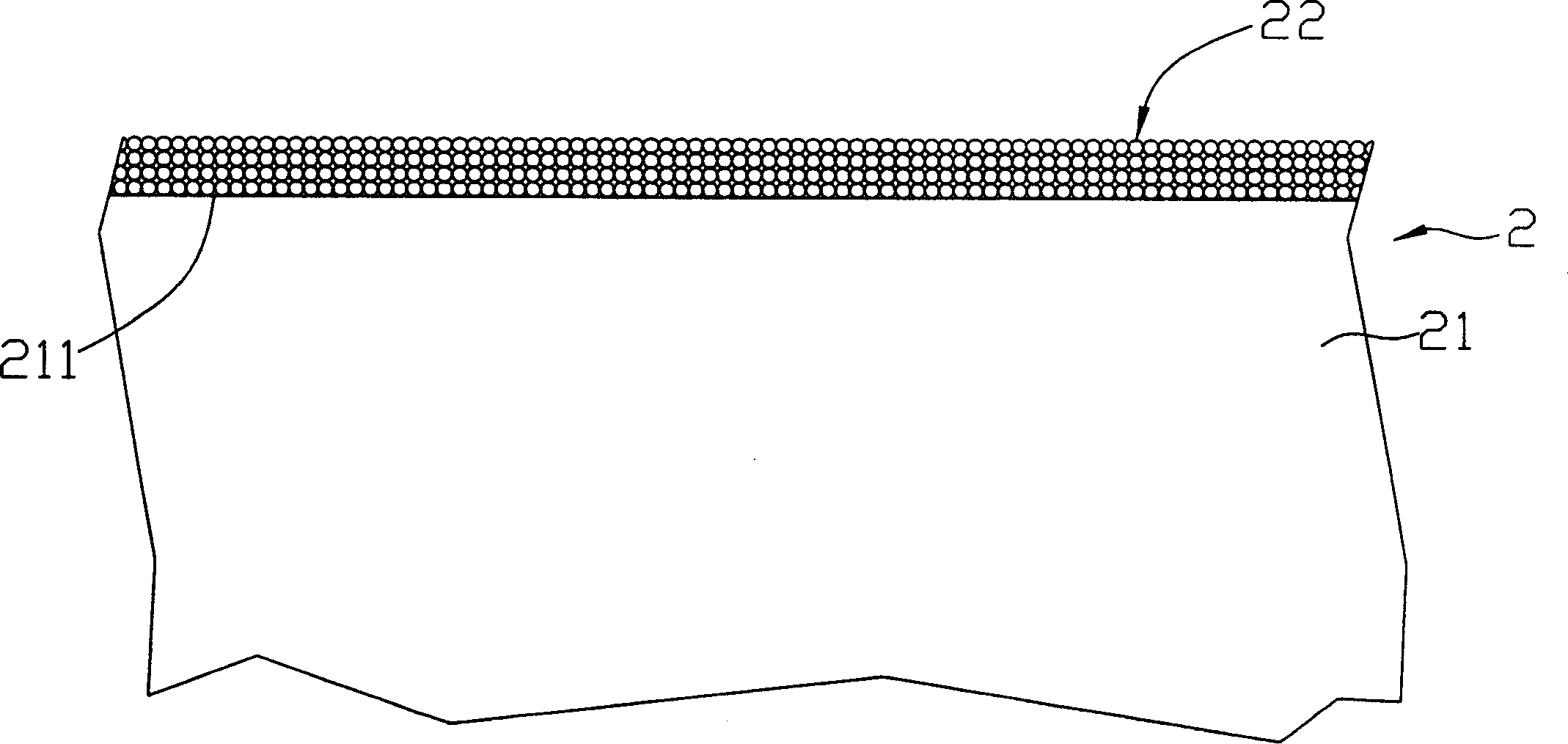

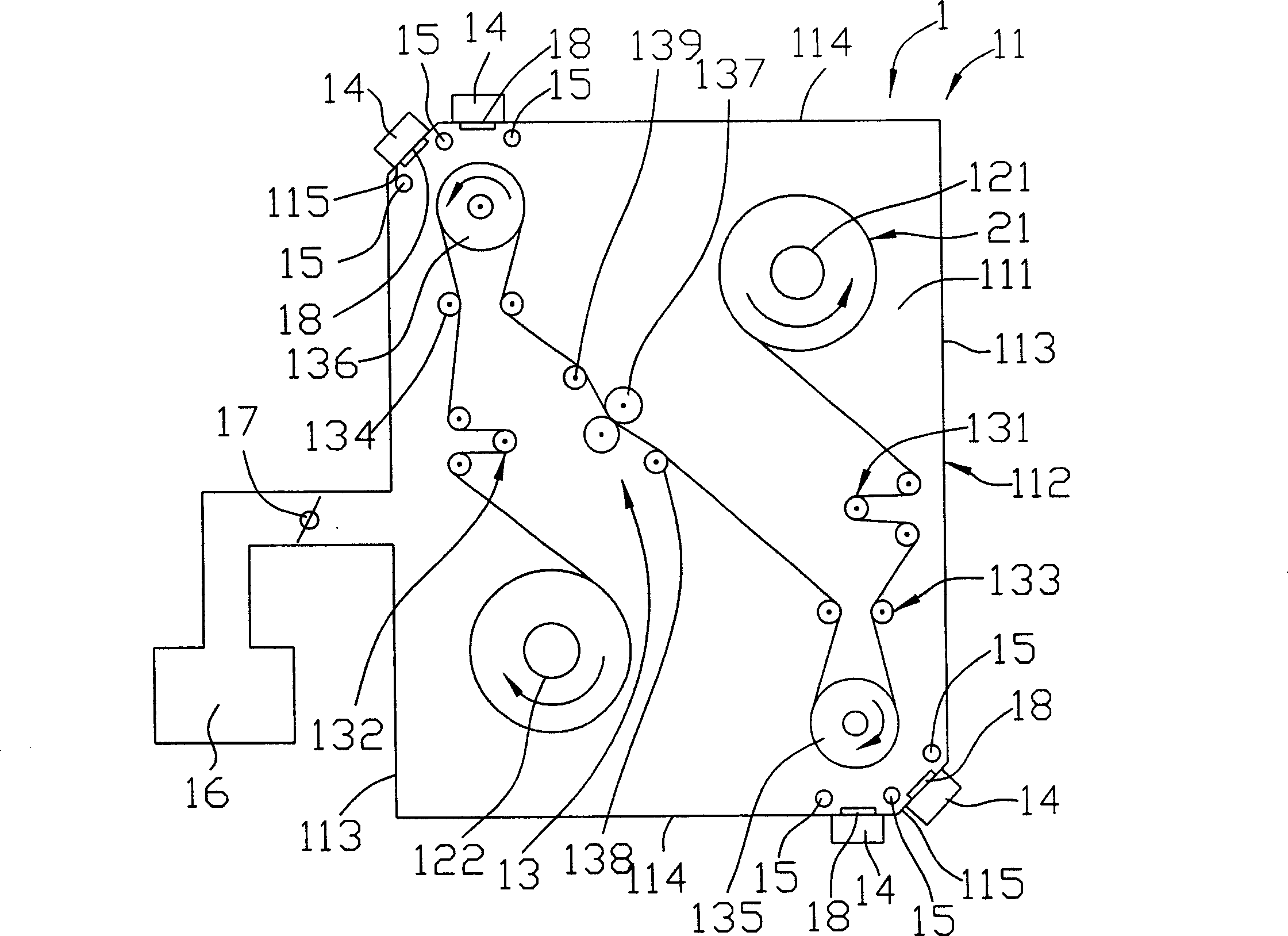

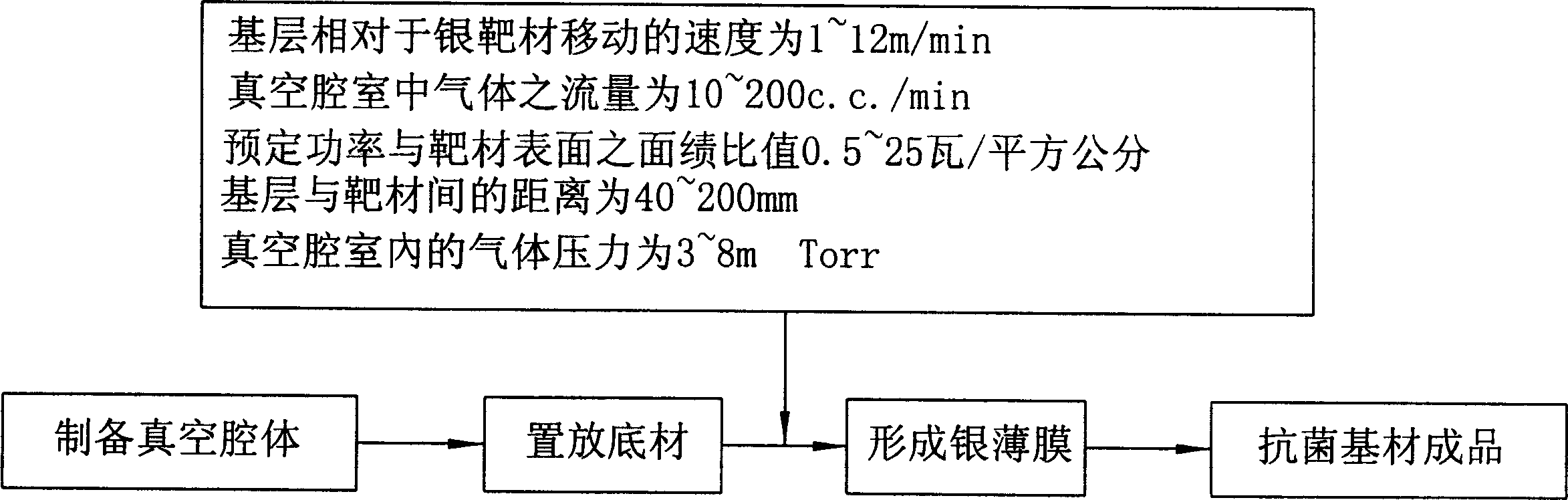

[0013] Refer to figure 1 , 2 A preferred embodiment of the manufacturing method of the present invention is to use a processing equipment 1 to manufacture a bacteriostatic substrate 2. The bacteriostatic substrate 2 includes a substrate 21 and a surface 211 formed on the substrate 21 The silver film 22 with a film thickness of 1-100 nanometers. In this embodiment, the silver film 22 is formed by stacking several layers of silver particles with a particle size of 1-5 nanometers. For the layer of silver particles, the material of the above-mentioned substrate 21 is not particularly limited. In this embodiment, a flexible substrate 21 such as cloth, nylon mesh, gauze, paper roll, and PVC film is used as a representative description. That is to say, all items that are expected to have antibacterial effects are applicable to the present invention, such as: filter materials, plastic products, medical products, paper products, and fiber products and other daily necessities. The specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com