Method for reducing critical dimension

A key size, photomask technology, applied in photomechanical processing of originals, patterned surface photoengraving process, instruments, etc. The effect of size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

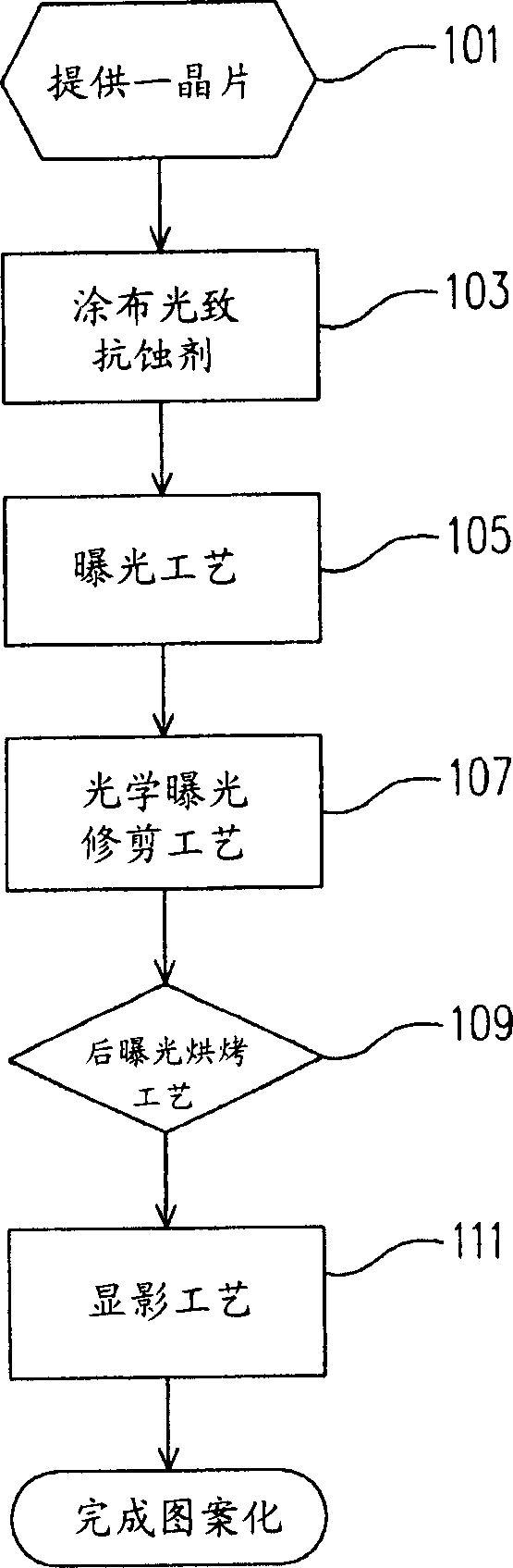

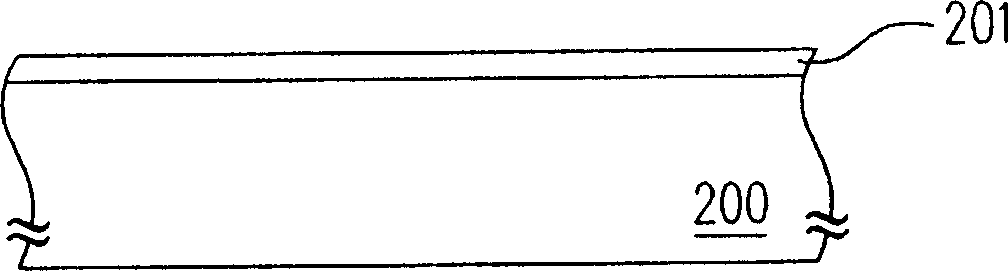

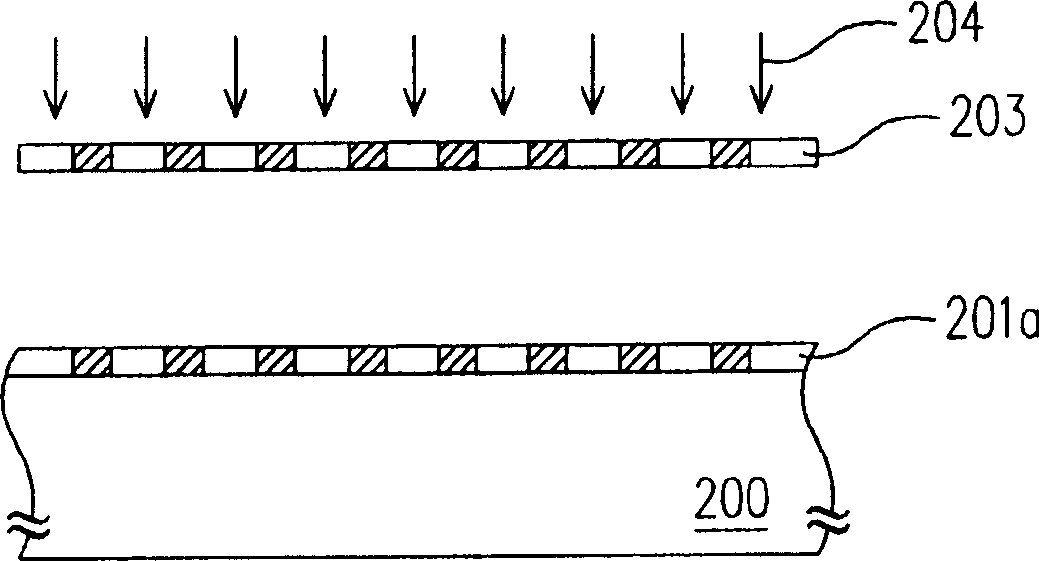

[0030] figure 1 Illustrated is a step-by-step diagram of the manufacturing process of the method for reducing critical dimensions according to a preferred embodiment of the present invention. Figure 2A to Figure 2D Illustrated is a cross-sectional view of the manufacturing process of a method for reducing critical dimensions according to a preferred embodiment of the present invention.

[0031] Please refer to figure 1 as well as Figure 2A , first provide a wafer 200 (step 101). The wafer 200 may be a wafer 200 on which transistors, memory cells, or other semiconductor elements have been formed, or a wafer 200 on which no semiconductor elements have been formed. The surface of the wafer 200 may be a dielectric layer, a conductive layer, a protective layer or any film layer requiring etching, doping and other processes. Next, a photoresist layer 201 is coated on the wafer 200 (step 103). The coating method is, for example, spin coating (spin coating), and the material of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com