Mechanochemical grinding process and method for increasing grinding end point accuracy

A grinding process, chemical mechanical technology, applied in the direction of grinding machines, manufacturing tools, metal processing equipment, etc., can solve the problems of conductor layer 150 residue, bridging phenomenon, reflection intensity disorder, etc., to improve reliability and product yield, avoid bridging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

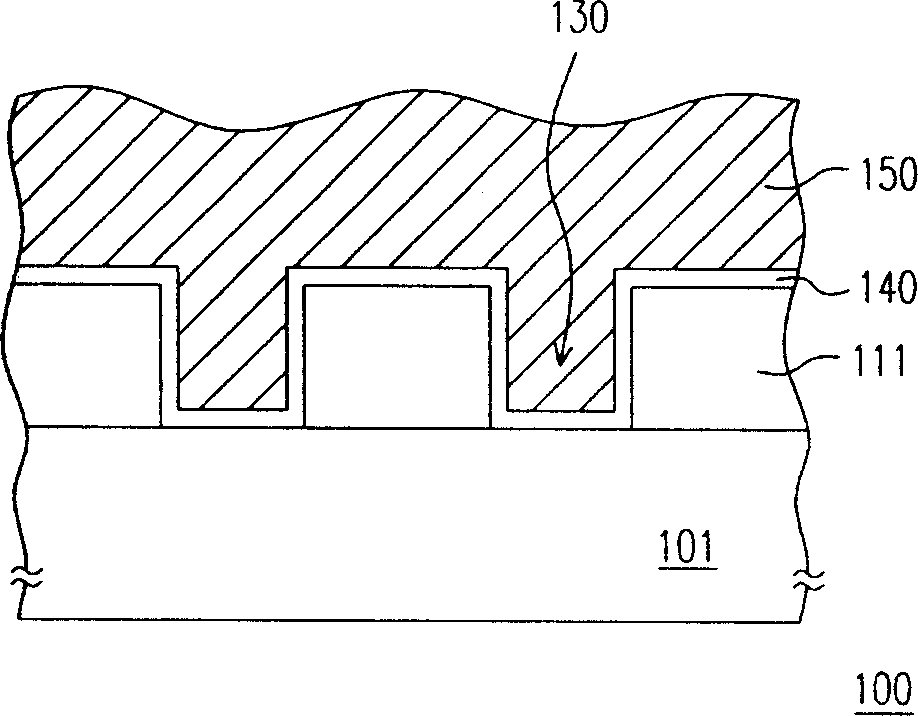

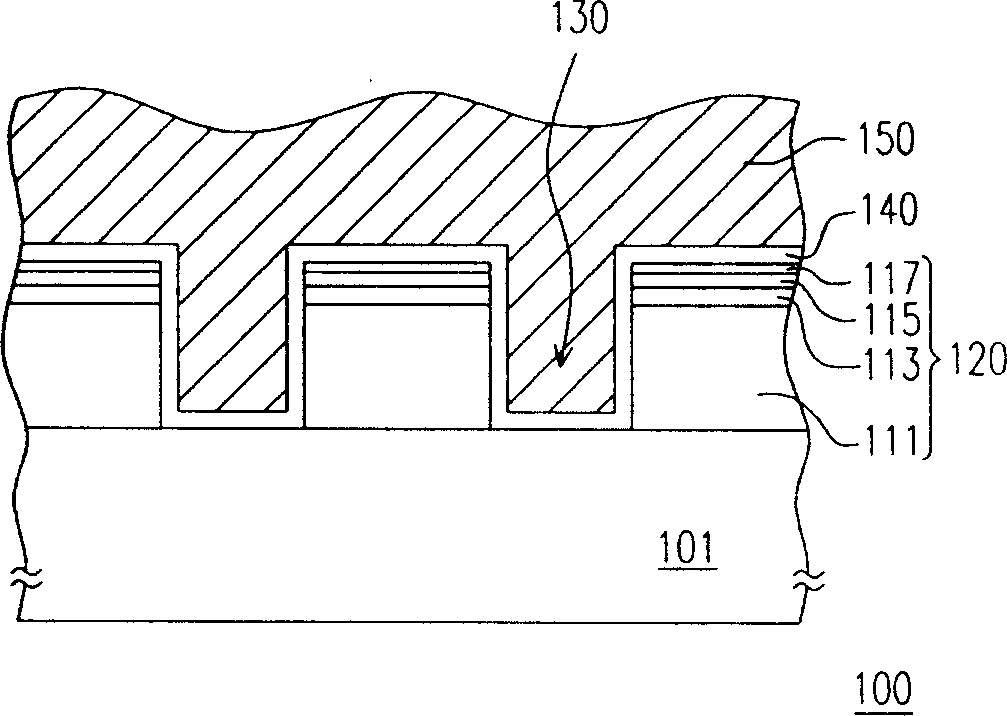

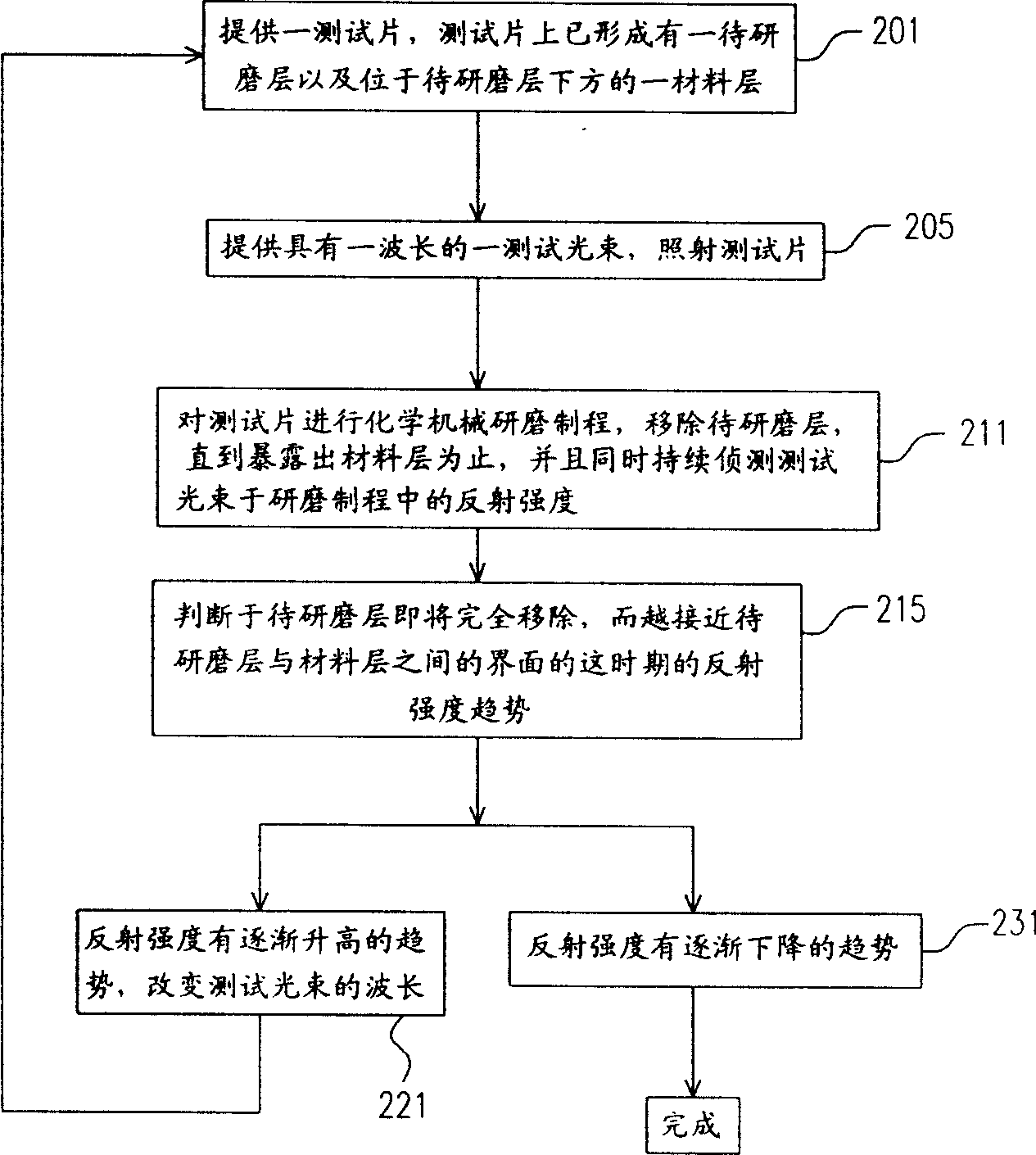

[0039] The method for increasing the polishing endpoint accuracy of the chemical mechanical polishing process of the present invention is performed before the chemical mechanical polishing process. Its details are as follows. figure 2 Illustrated is a flow chart of steps of a method for increasing the accuracy of the polishing end point of a chemical mechanical polishing process according to an embodiment of the present invention. image 3 It is a cross-sectional view of a test piece structure according to an embodiment of the present invention.

[0040] Please refer to figure 2 and image 3 Firstly, a test piece 300 is provided, on which a layer 310 to be polished and a material layer 320 below the layer 310 to be polished have been formed (step 201 ). The layer to be polished 310 includes, for example, an adhesive layer 340 and a conductive layer 350 . The material of the adhesive layer 340 is, for example, titanium nitride / titanium (TiN / Ti). The material of the condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com