Refrigeration lubricant composition

A technology of lubricating oil composition and refrigerator, which is applied in the direction of lubricating composition, petroleum industry, base materials, etc., can solve the problems of low-temperature long-term stability reduction, etc., and achieve excellent electrical insulation, low viscosity, and long-term low-temperature stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

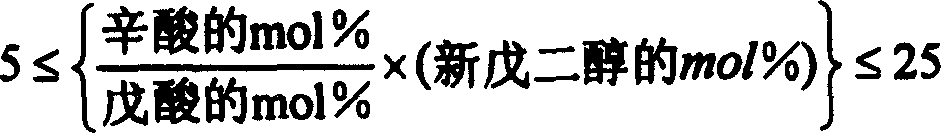

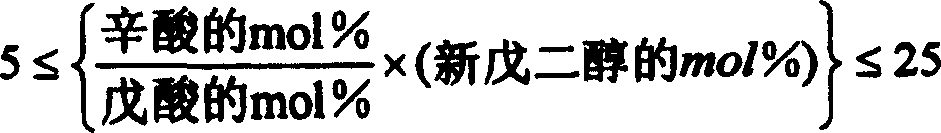

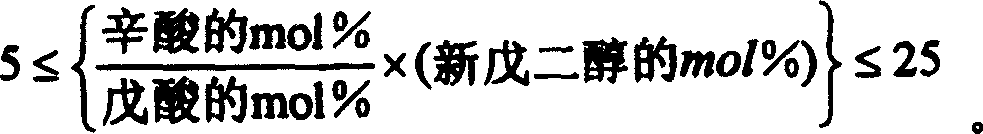

[0033] As for the preparation method of the ester used in the present invention, it can be prepared by any method within the range of not impairing the above-mentioned properties, and there is no particular limitation. The above esters can be produced, for example, as follows. First, mix saturated straight-chain carboxylic acids with respect to 1 equivalent of hydroxyl groups of mixed alcohols so that carboxyl groups reach 1.0 to 1.5 equivalents, or preferably 1.05 to 1.3 equivalents from the viewpoint of production efficiency and economical efficiency, and add a catalyst as needed . In a nitrogen stream, the mixture was reacted at 220-260° C. for 3-15 hours, and when the hydroxyl value reached below 2.0 mgKOH / g, the excess carboxylic acid was removed under reduced pressure. Thereafter, after deacidification with alkali, operations such as adsorption treatment with activated clay, acid clay, and synthetic adsorbent, steam processing, etc. are performed alone or in combination...

Embodiment 11

[0060] (Example 1.1: Preparation of Esters)

[0061] In a 1 liter 4-neck flask equipped with a thermometer, nitrogen inlet pipe, stirrer and condenser, the mixed alcohol and mixed carboxylic acid shown in Table 1 are charged, so that the equivalent ratio of the hydroxyl group of the mixed alcohol and the carboxyl group of the mixed carboxylic acid is 1:1.1, the reaction was carried out under normal pressure while distilling off the reaction water at 220° C. under nitrogen flow. During the reaction, the hydroxyl value was monitored, and when it dropped to 2.0 mgKOH / g, the reaction was terminated. Then, stripping was performed under a reduced pressure of 1 to 5 kPa, and unreacted carboxylic acid was removed over 1 hour. An aqueous potassium hydroxide solution was added to the obtained reaction mixture to wash with water, and the washing with water was repeated five times so that the pH of the waste water became neutral. Next, under the conditions of 100° C. and 1 kPa, the obta...

Embodiment 12~16

[0063] Except having used the mixed alcohol and mixed carboxylic acid shown in Table 1, it carried out similarly to Example 1, and obtained ester (ester B-F). The compositions of the obtained esters B to E are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com