Mini-packing silicon microphone

A technology for silicon microphones and micro-seals, which is applied in the direction of electrostatic transducer microphones, sensors, electrical components, etc., can solve the problems of less packaging literature and patent reports, and achieve the goals of avoiding environmental impact, reducing packaging height, and reducing packaging volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

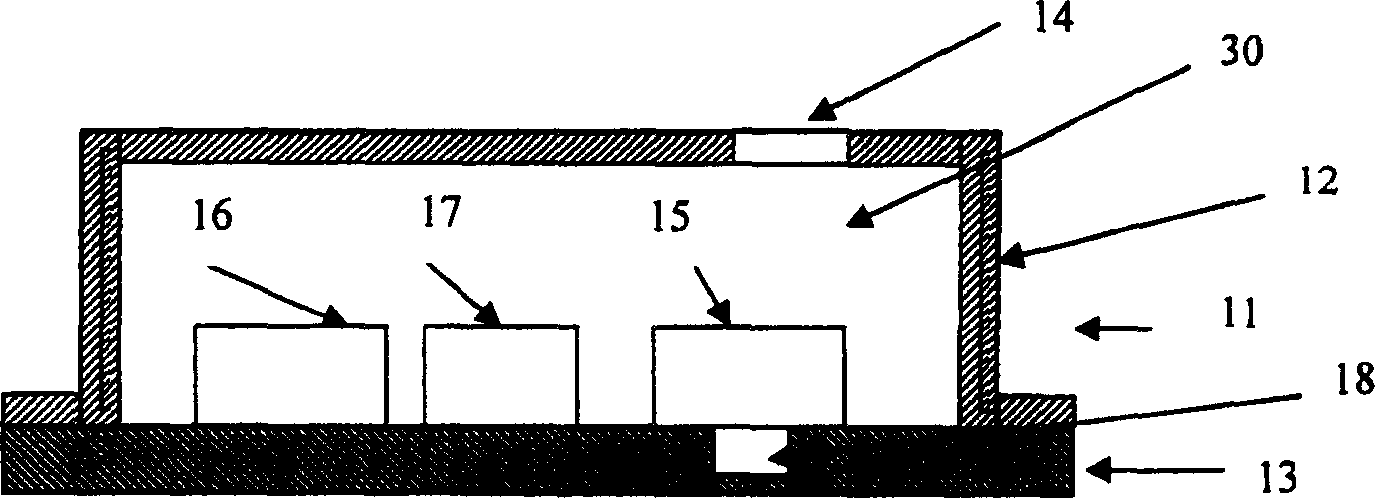

[0027] Such as figure 1 As shown, the package structure 11 proposed by the silicon microphone micro package of the present invention is composed of a metal cap 12 and a base 13 . The metal cap 12 is electrically connected to the base 13 to form an electromagnetic shielding cavity 30, thereby protecting the silicon micro-microphone chip 15, IC chip 16 and capacitor 17 packaged inside it from external electromagnetic interference. There are one or more small holes 14 on the top or side of the metal cap 12; there is an acoustic cavity 18 on the base, and these structures can ensure the acoustic requirements of the silicon microphone during operation.

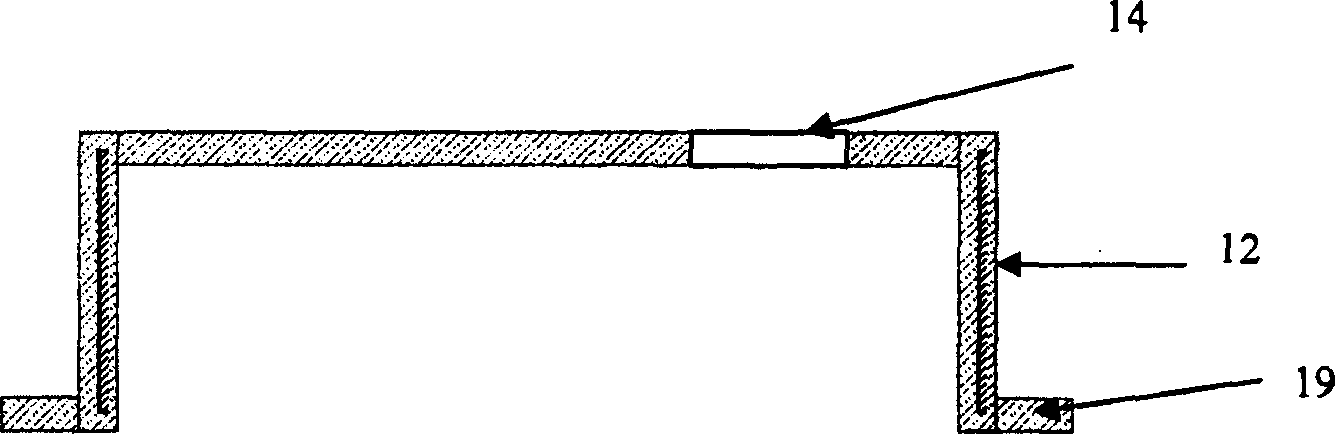

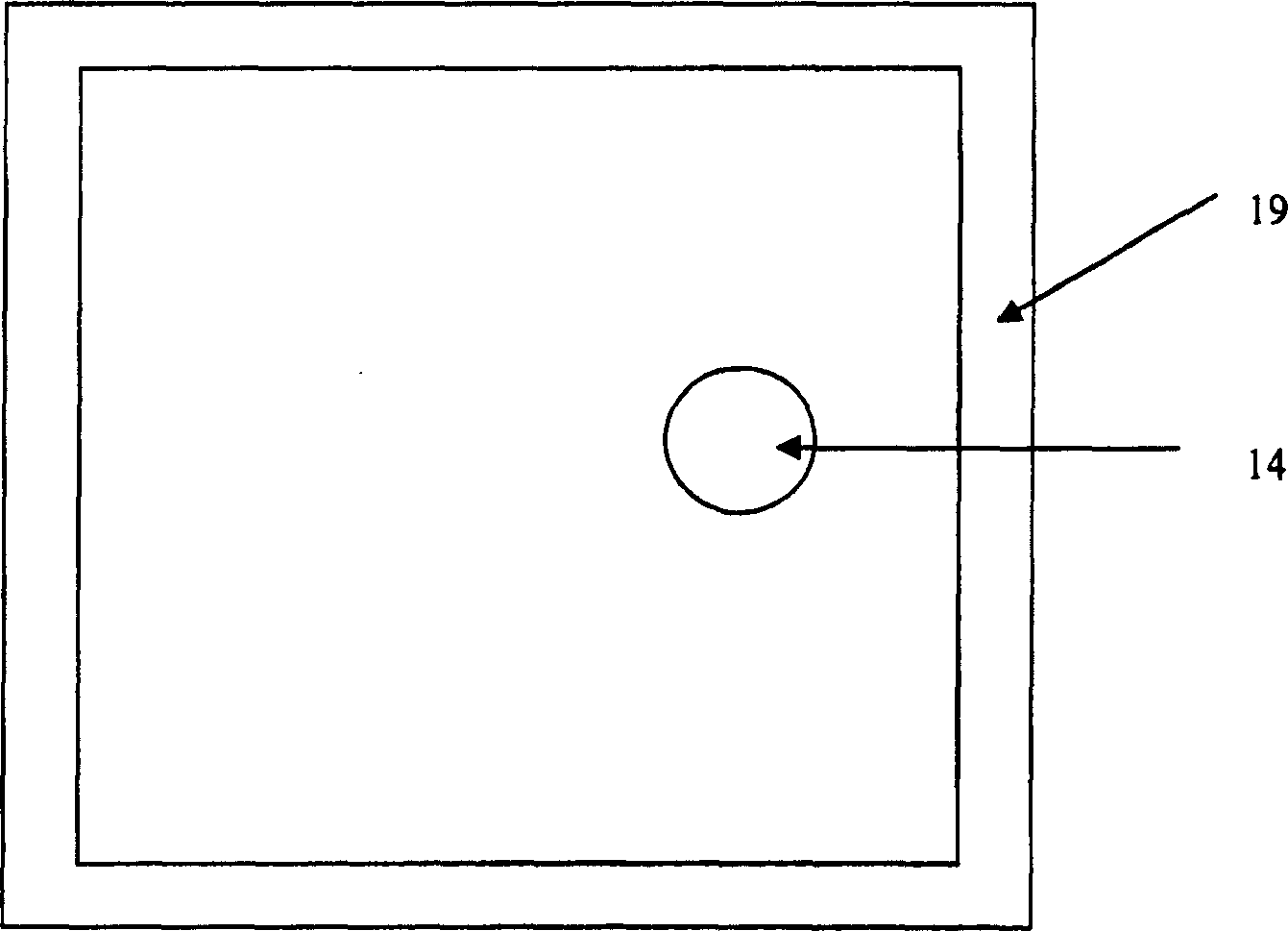

[0028] Figure 2a , b are a cross-sectional view and a top view of the metal cap 12, respectively. The edge of the metal cap 12 is folded to form a small hem 19, which can be realized by stretching or punching. The crimping allows the metal cap 12 and the base 13 to have a large enough contact area to form a strong package. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com