Circulator and manufactureing method

A manufacturing method and technology of a circulator, applied in the direction of bearings, linear motion bearings, shafts and bearings, etc., can solve the problems of difficult mold opening, high yield, cumbersome and time-consuming processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

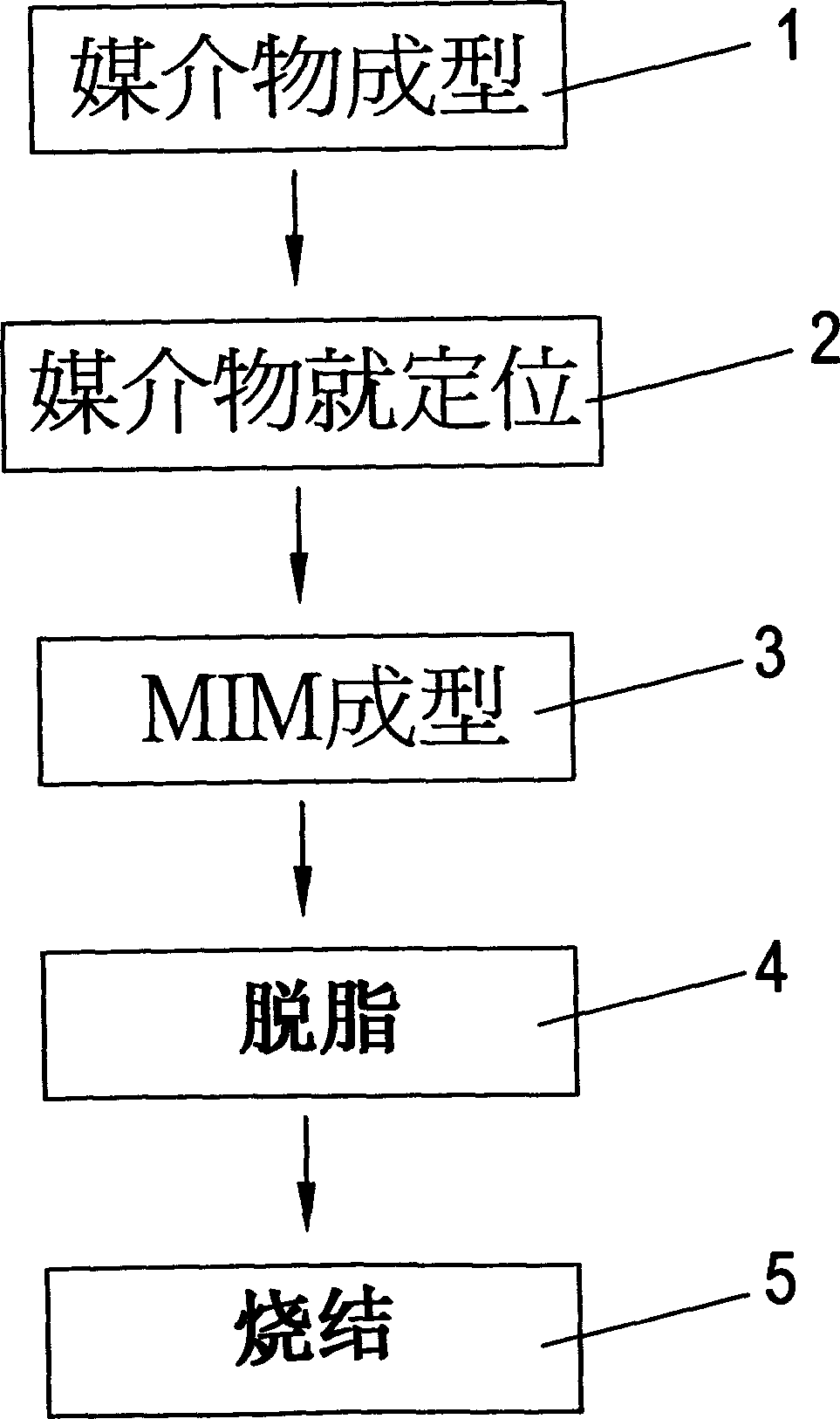

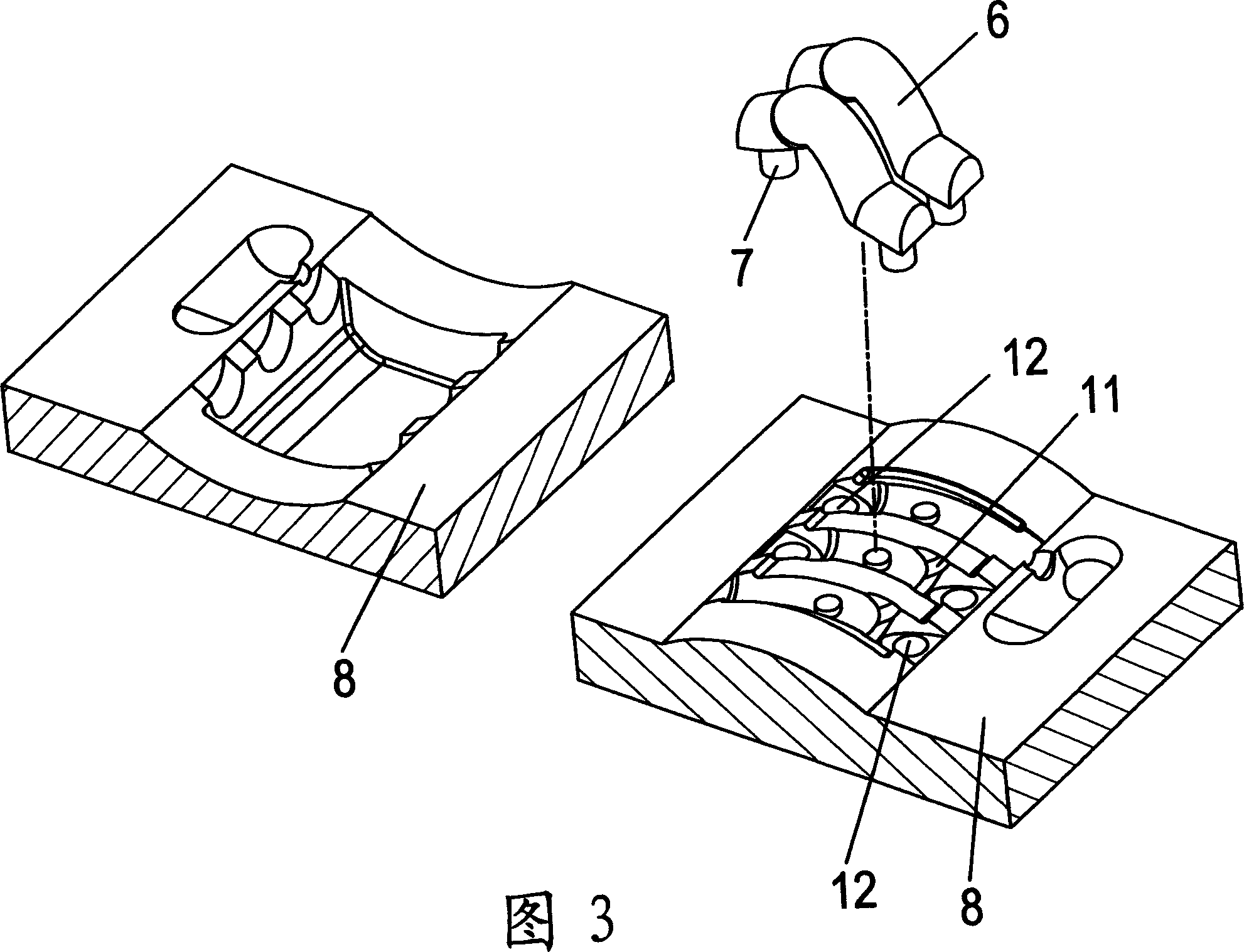

[0021] See first figure 1 , figure 2 ,image 3, Figure 4 , Figure 5 and Image 6 Shown, a kind of circulator of the present invention and manufacturing method, during implementation: the circulator of the present invention and manufacturing method, be the circulator that is applied on the bearing of linear motion, comprise the following steps:

[0022] Medium forming 1. Lubricating substances (such as wax, etc.), powdery polymer materials (such as polyethylene, or polypropylene, etc.), after material selection, add binders, such as paraffin, polyethylene, polypropylene, etc. Stir evenly (you can use a kneading mixer at a temperature between 50 degrees and 100 degrees), and then inject the molding medium from the mold;

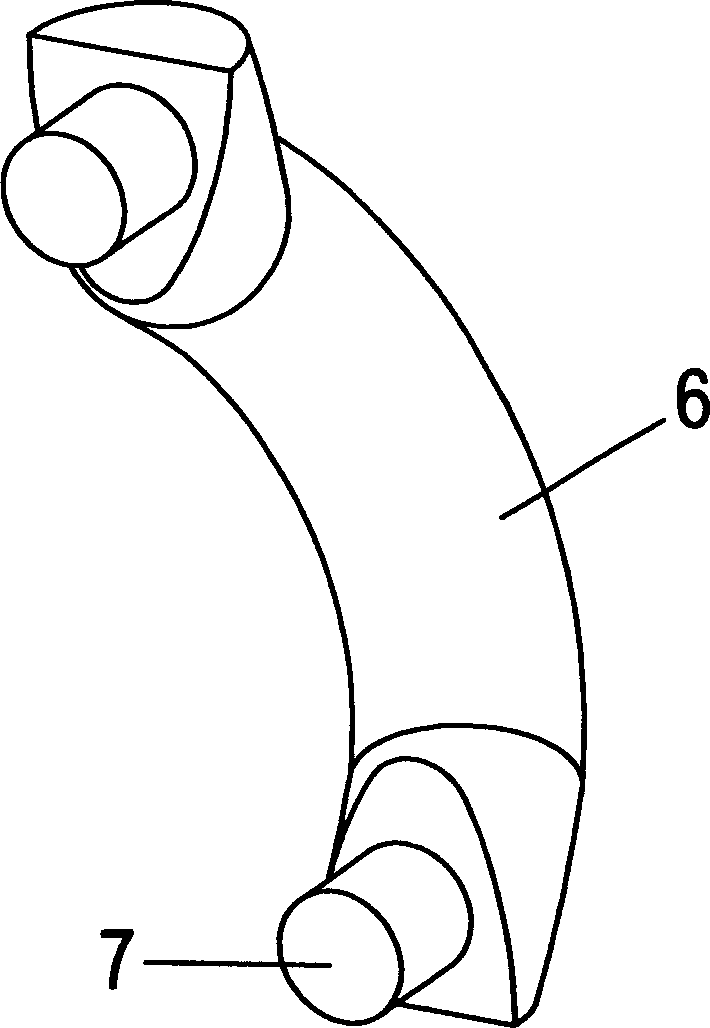

[0023] The medium positioning 2 is to place the formed medium spirally bent circular cylinder 6 in the circulator mold 8;

[0024] MIM molding 3 is a rough blank mold 10 that is made by injecting metal powder 9 from the circulator mold 8 and covering the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com