Li-doped p-Zn1-xMgxO crystal film and method for preparing same

A technology of p-zn1-xmgxo and crystal, which is applied in the field of Li-doped p-Zn1-xMgxO crystal film and its preparation, can solve the problem of deep acceptor energy level, low repeatability and stability of p-type conductance, Low solid solubility and other problems, to achieve the effect of high solid solubility, shallow acceptor energy level, good stability and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

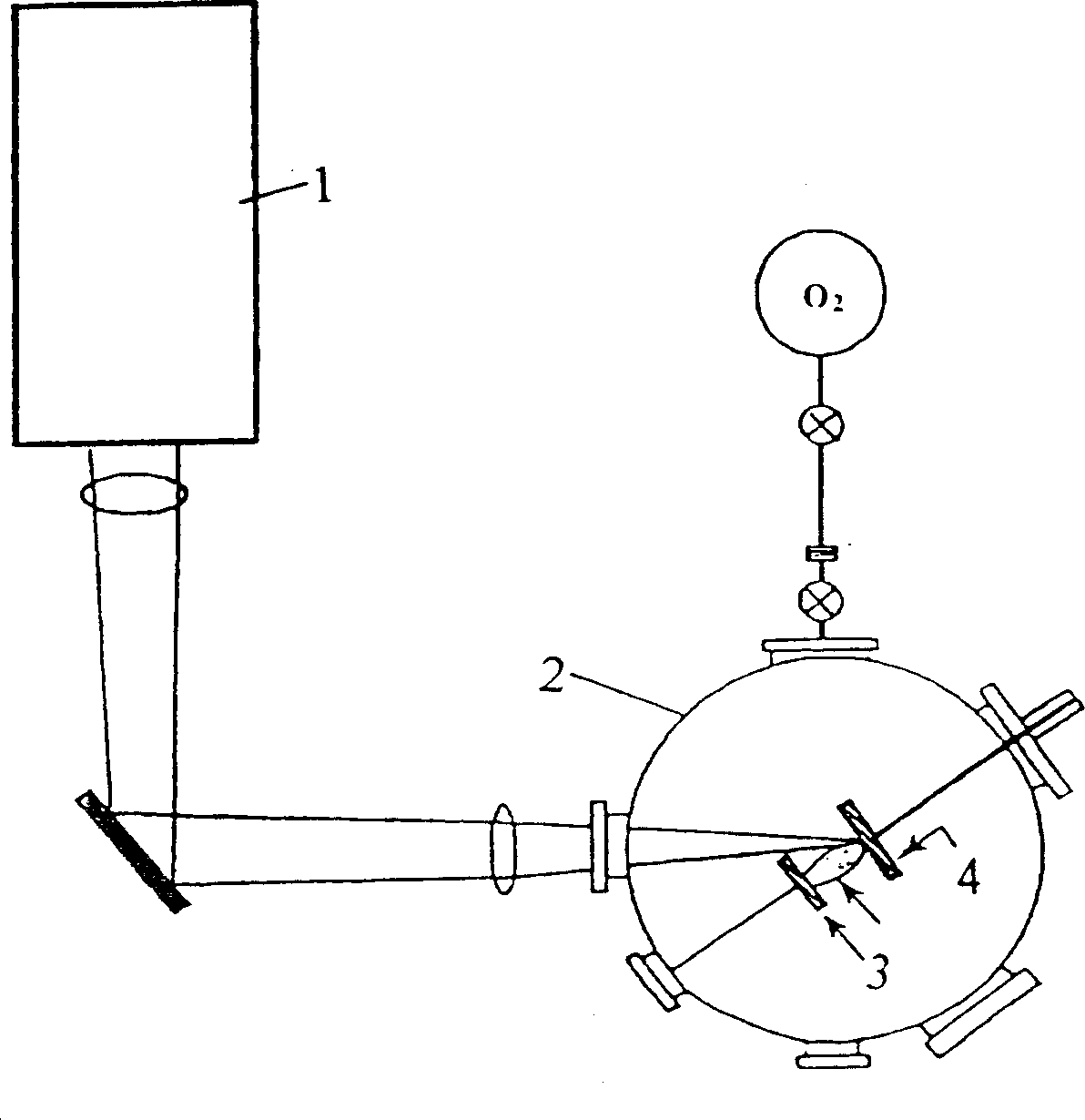

[0017] The following combination figure 1 , the present invention will be further illustrated by examples. Growth of p-Zn on glass substrate 1-x Mg x O crystal thin film, concrete steps are as follows:

[0018] 1) Sintering of ceramic targets Weigh high-purity ZnO, MgO and Li with a purity >99.99% 2 CO 3 powder, so that the molar ratio of MgO to ZnO is 1:9, Li 2 CO 3 The molar content is 0.4%. The weighed ZnO, MgO and Li 2 CO 3 The powder is mixed and poured into a ball mill jar equipped with agate balls, and milled on a ball mill for 20 hours. The purpose is to mix the raw materials evenly and refine them to a certain extent, so as to facilitate the forming and sintering of ceramic targets. Then the raw materials are separated and dried, and pre-sintered at 800 °C to make Li 2 CO 3 Decomposed into Li 2 O and CO 2 , and put CO 2 discharge. The calcined powder is ball-milled again, dried, then added with a binder for grinding, and pressed into shape. Put the mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com