Adhesive sheet for use in cutting

An adhesive sheet and adhesive layer technology, applied in the directions of adhesives, film/sheet adhesives, metal processing, etc., can solve the problems of cutting tape breakage, insufficient breaking strength, insufficient breaking elongation, etc. Achieving the effect of improving operability and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] (Manufacturing of base material film)

[0075] The "trade name: Ceras" manufactured by Mitsubishi Chemical Co., Ltd. was supplied to a T stretch film forming machine (set temperature 230°C) manufactured by Plastics Corporation for film formation, and a base material film with a thickness of 100 μm and a width of 35 cm was produced. . "Trade name: ぜラス" manufactured by Mitsubishi Chemical Corporation is a propylene-based thermoplastic elastomer containing a propylene component and an ethylene propylene rubber component.

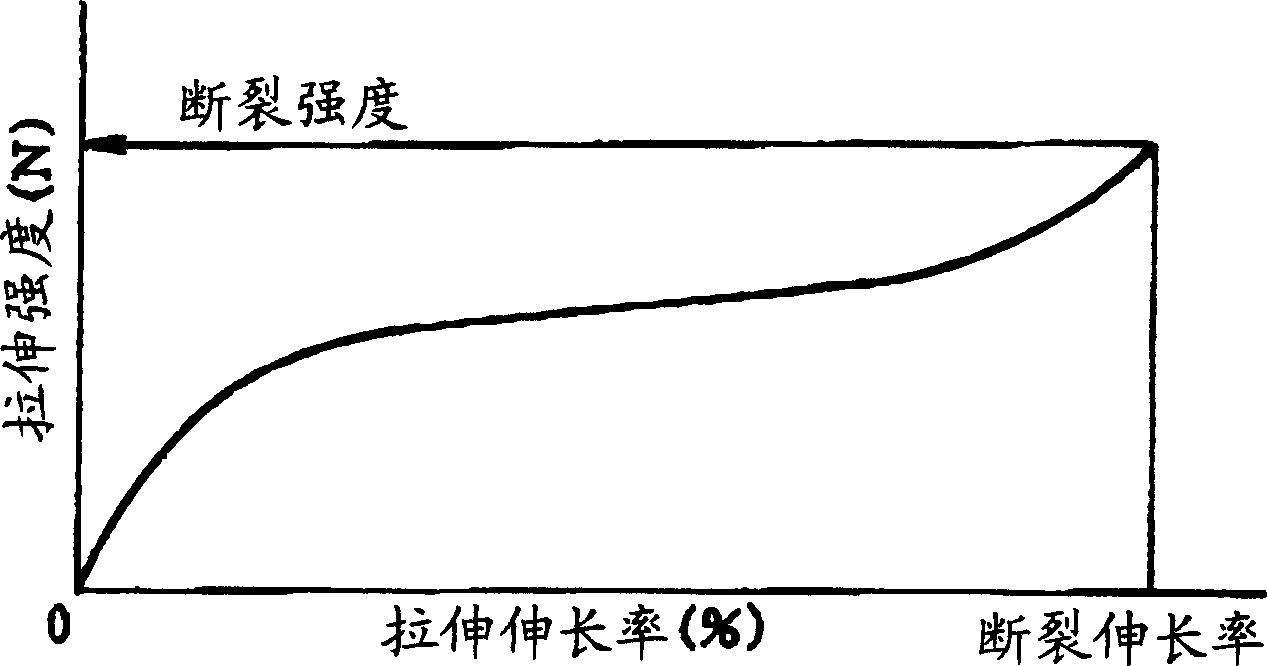

[0076] (Evaluation of physical properties of base material film)

[0077] For the obtained base material film, various physical properties of elastic tensile modulus, yield point elongation, breaking elongation, and penetration resistance were evaluated.

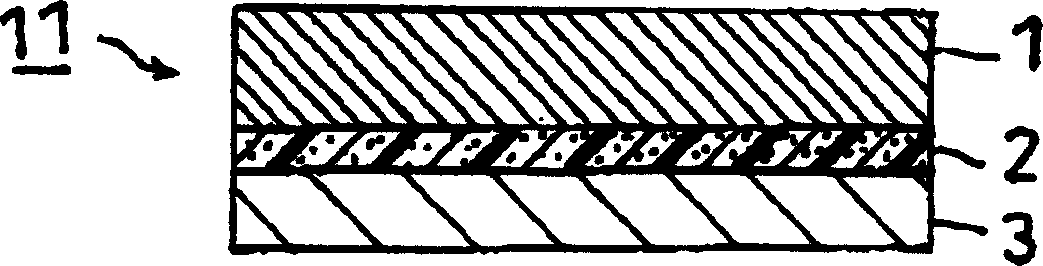

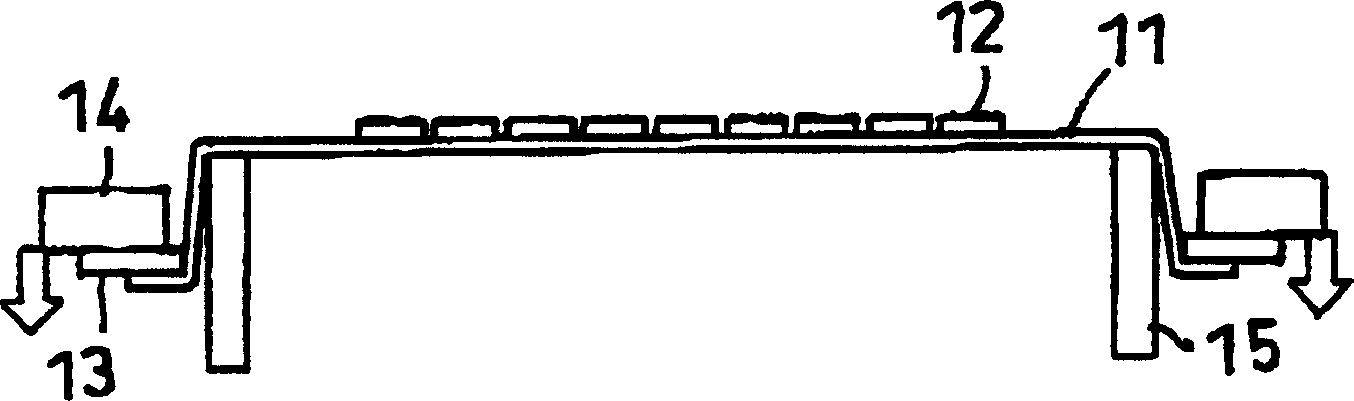

[0078] (Manufacture of adhesive sheets for cutting)

[0079] By a conventional method, 90 parts by weight of butyl acrylate and 10 parts by weight of acrylic acid were copolymerized in a toluene solution t...

Embodiment 2

[0082] (Manufacturing of base material film)

[0083] The "brand name: Paramit SA-F" (methacrylate resin) manufactured by Curaray (Company) was calendered and formed into a film (set temperature 170°C) to produce a base film with a thickness of 100 μm and a width of 35 cm.

[0084] (Evaluation of physical properties of base material film)

[0085] In the same manner as in Example 1, the physical properties of the obtained base film were evaluated. The results are shown in Table 1 below.

[0086] (Manufacture of adhesive sheets for cutting)

[0087] The adhesive solution prepared in Example 1 was coated on the corona-treated surface of the substrate film obtained by the above method, and cross-linked by heating at 80°C for 10 minutes to form a 10μm-thick UV-curable adhesive layer . Then, the separator was bonded to the adhesive layer to produce an ultraviolet curable adhesive sheet for dicing.

Embodiment 3

[0089] (Manufacturing of base material film)

[0090] Teijin Chemicals Co., Ltd. "brand name: ヌベラン" (polyester elastomer resin) was supplied to a T stretch film forming machine (set temperature 230°C) manufactured by Plastics Corporation to form a film to produce a thick film. 100μm, 35cm wide substrate film.

[0091] (Evaluation of physical properties of base material film)

[0092] The physical properties of the obtained base material film were evaluated in the same manner as in the first embodiment. The results are shown in Table 1 below.

[0093] (Manufacture of adhesive sheets for cutting)

[0094]The adhesive solution prepared in Example 1 was applied to the corona-treated surface of the substrate film obtained by the above method, and crosslinked and cured at 80°C for 10 minutes to form a 10μm-thick UV-curable adhesive layer . Then, the separator was bonded to the adhesive layer to produce an ultraviolet curable adhesive sheet for dicing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com