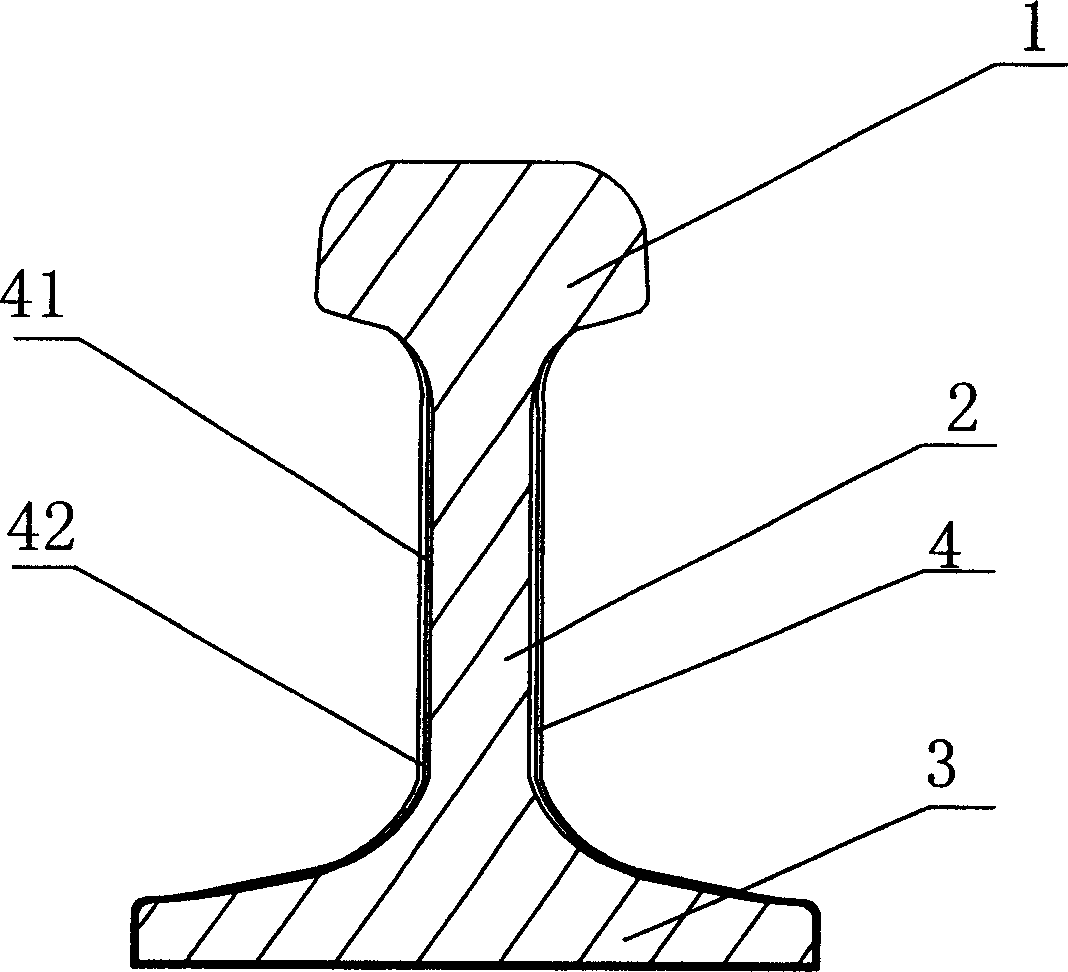

Corrosion-resisting steel rail and process for producing the same

A production method and corrosion-resistant technology, which are applied in the plating, coating, metal material coating process of superimposed layers, etc., can solve the problems of hydrogen absorption of high-carbon rails, large investment, brittle fracture, etc., and achieve low production costs. , The production line is simple, and the anti-scratch performance is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] On the arc spraying production line of corrosion-resistant steel rails, the finished steel rails are placed upright on the roller table line driven by the motor and move at a constant speed, and the steel rails enter the work of shot blasting or sandblasting, cleaning, arc spraying and organic coating spraying or rolling in sequence. Area. First, use a shot blasting machine to clean the oxide scale and rust on the rail waist and rail bottom to ensure that there is no oxide scale and rust on both sides of the rail waist and rail bottom, and the surface roughness is Rz2.5, and then use clean and dry compressed air to blow Sweep the floating dust on the surface of rail waist and rail bottom. Then arrange two arc spraying guns side by side and longitudinally on both sides of the rail waist and rail bottom, spray the metal layer formed by Ф2.0mm zinc wire, spray the arc voltage at 30V, the current at 160A, and the atomizing gas pressure at 0.65 MPa, the spray gun is 150mm a...

Embodiment 2

[0025] On the arc spraying production line of corrosion-resistant steel rails, the finished steel rails are placed upright on the roller table line driven by the motor and move at a constant speed, and the steel rails enter the work of shot blasting or sandblasting, cleaning, arc spraying and organic coating spraying or rolling in sequence. Area. First, use a sandblasting machine to clean the scale and rust on the rail waist and rail bottom to ensure that there is no scale and rust on both sides of the rail waist and rail bottom, and the surface roughness is Rz5, and then use clean and dry compressed air to blow the rails The surface of the waist and rail bottom is dusty. Then arrange three arc spraying guns side by side and vertically on both sides of the rail waist and the bottom side of the rail respectively, and spray the metal layer formed by Ф3.0mm aluminum wire. The spraying arc voltage is 30V, the current is 200A, and the atomizing gas pressure is 0.65 MPa, the spray ...

Embodiment 3

[0027] On the arc spraying production line of corrosion-resistant steel rails, the finished steel rails are placed upright on the roller table line driven by the motor and move at a constant speed, and the steel rails enter the work of shot blasting or sandblasting, cleaning, arc spraying and organic coating spraying or rolling in sequence. Area. First, use a shot blasting machine to clean the oxide scale and rust on the rail waist and rail bottom to ensure that there is no oxide scale and rust on both sides of the rail waist and rail bottom, and the surface roughness is Rz12.5, and then use clean and dry compressed air to blow Sweep the floating dust on the surface of rail waist and rail bottom. Then arrange four arc spraying guns side by side and longitudinally on both sides of the rail waist and rail bottom, spray the metal layer formed by Ф2.0mm zinc-aluminum alloy wire, the spraying arc voltage is 30V, the current is 160A, the atomizing gas The pressure is 0.65MPa, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com