Power components with composite heat sink

A technology of composite heat dissipation layer and power components, which is applied in the direction of semiconductor/solid-state device parts, electrical components, electric solid-state devices, etc., can solve the problems of high manufacturing cost, increase the volume of power components, and complicated installation process, so as to reduce the temperature rise , improve the service life, and the effect of uniform weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

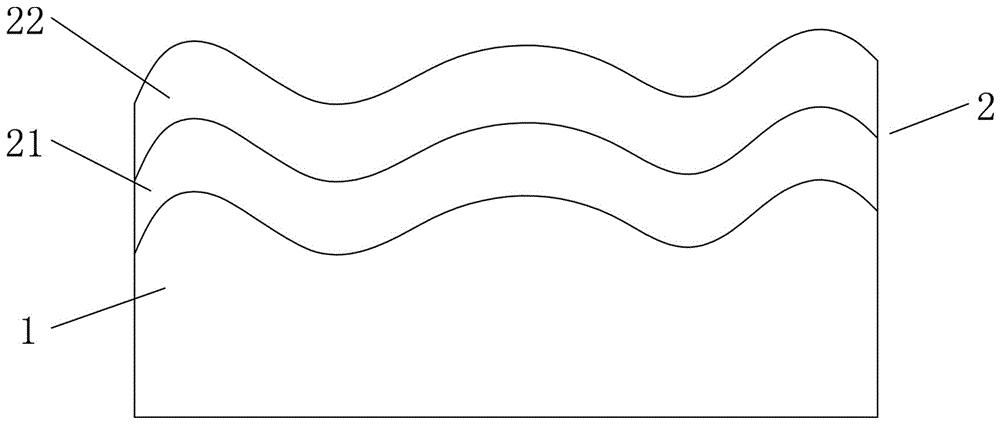

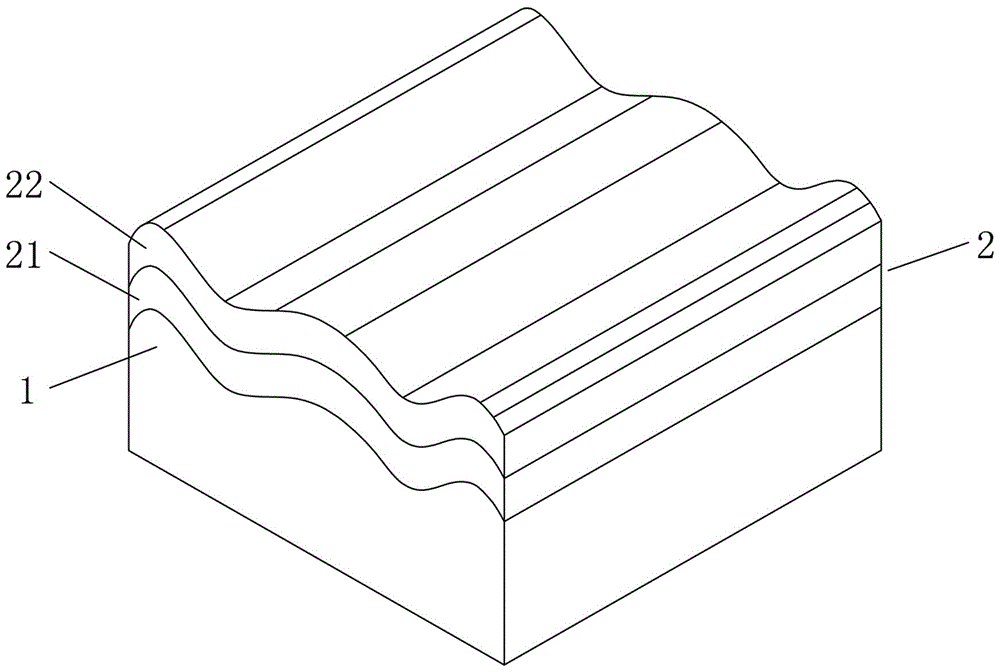

[0031] Embodiment one, see figure 1 and figure 2 As shown, a compound heat dissipation layer for power components, the composite heat dissipation layer 2 is composed of a layer of insulating thin layer 21 and a layer of solid metal heat dissipation thin layer 22, the bottom layer of the composite heat dissipation layer 2 is an insulating thin layer 21, located in The bottom insulating thin layer 21 is used for close contact with the outer surface of the power component.

[0032] The insulating thin layer 21 is polyester film, polypropylene film, etc., and its thickness is between 0.001mm and 0.200mm.

[0033] The solid metal heat dissipation thin layer 22 is a metal aluminum thin layer, a metal silver thin layer, a metal zinc thin layer, a zinc aluminum alloy thin layer, etc., and its thickness is between 0.10 mm and 0.30 mm.

[0034] A power component with a composite heat dissipation layer, including a power component main body 1 and a composite heat dissipation layer 2, ...

Embodiment 2

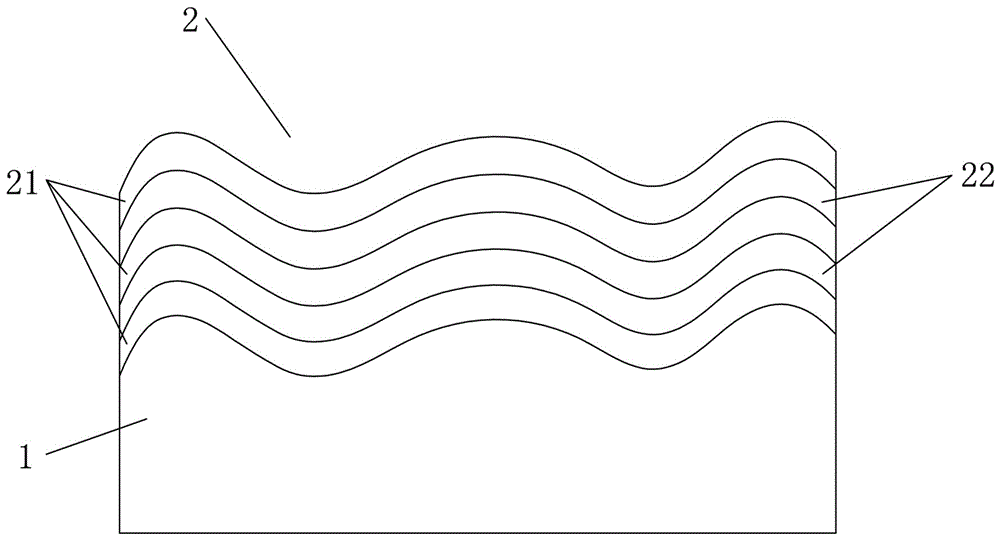

[0038] Embodiment two, the difference with embodiment one is: see image 3 and Figure 4 As shown, the heat dissipation composite layer 2 includes more than two layers of insulating thin layers 21 and more than two layers of solid metal heat dissipation thin layers 22, and the insulating thin layers 21 and solid metal heat dissipation thin layers 22 are stacked alternately.

Embodiment 3

[0039] The third embodiment differs from the power component with a composite heat dissipation layer in the first embodiment in that it includes a power component main body with surface insulation, and at least one solid metal heat dissipation thin layer is provided on the outer surface of the power component main body. Since the surface of the main body of the power component itself is insulated, the insulating thin layer at the bottom of the composite heat dissipation layer can be omitted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com