Chlorinated polyethylene drying process

A technology of chlorinated polyethylene and drying process, which is applied in the field of drying process, and can solve the problems of easy fluctuation of product water content, high labor intensity of workers, and small output of fluidized bed, so as to achieve stable product water content and reduce labor intensity of workers , the effect of temperature stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

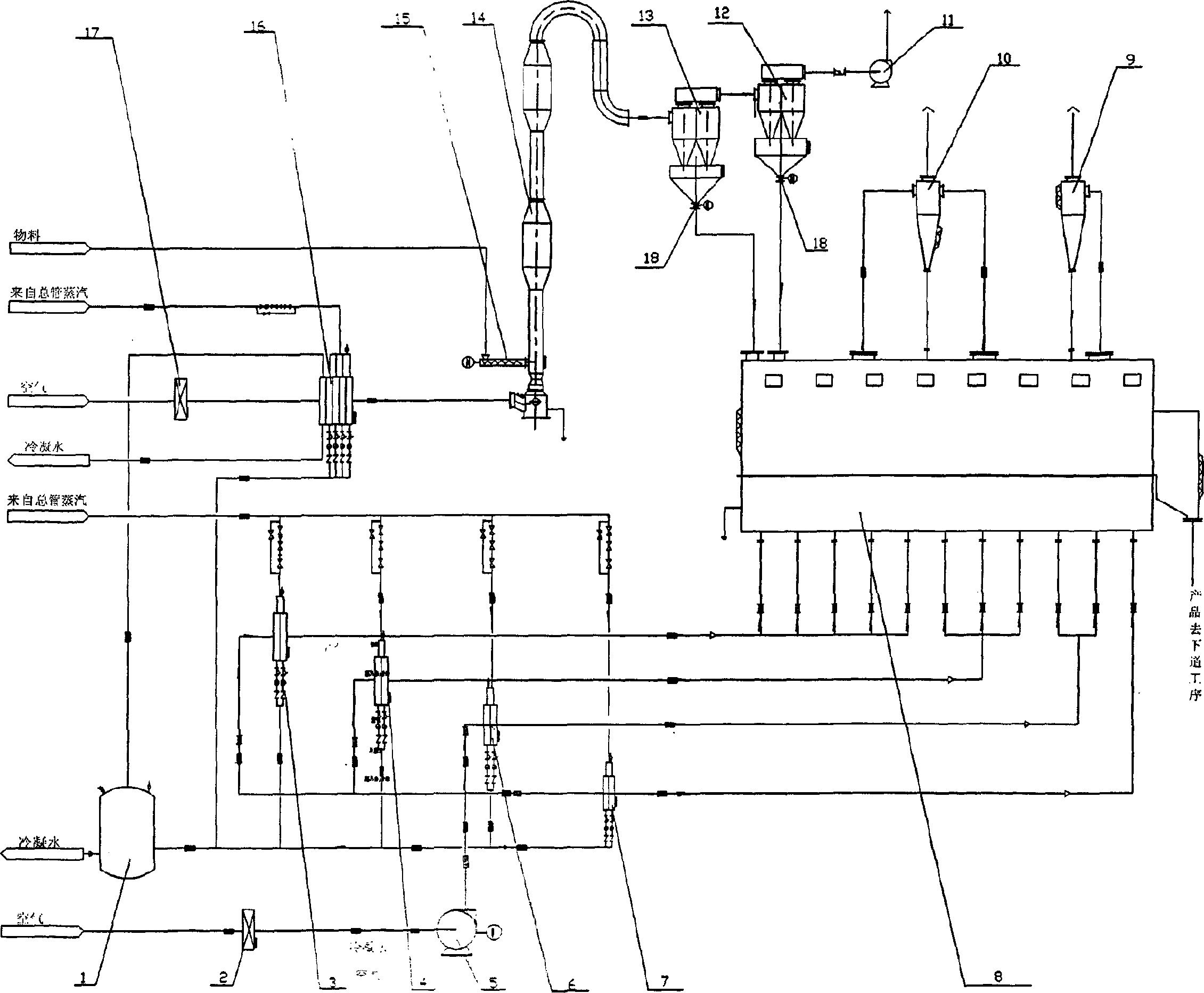

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0022] figure 1 Among them, the heat source of the drying system adopts hot air, and the first-level drying: the wet material is fed into the pulse air dryer 14 by the conveying auger 15, and the dry air is filtered through the 2# air filter 17, and the 5# steam heat exchanger 16 The heat-exchanging high-temperature air is fully contacted, and the material is initially dried in the pulse airflow dryer 14, and enters the fluidized bed dryer 8 through the corresponding air shutoff devices 18 at the bottom of the cyclone dust collector II12 and cyclone dust collector I13, and the exhaust gas passes through the induced draft fan. 11 After pressurization, it is emptied by the emptying pipe.

[0023] Secondary drying: The material after primary pre-drying is fed into the fluidized bed dryer 8 through the air locker 18 through the slide pipe. The air is filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com