Solar, heat-pump composite, stepped-heating type energy-storage hot-water making method and special device

A technology of graded heating and production methods, which is applied in the field of solar energy utilization, can solve the problems of roof installation bearing capacity, increase the volume of water tanks, and the impact of installation adaptability, etc., and achieve the goals of solving load distribution problems, high solar energy utilization, and low operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The solar energy-heat pump of the present invention, the method for producing hot water with hierarchical heating energy storage and the special device using the method can be further illustrated by the following examples:

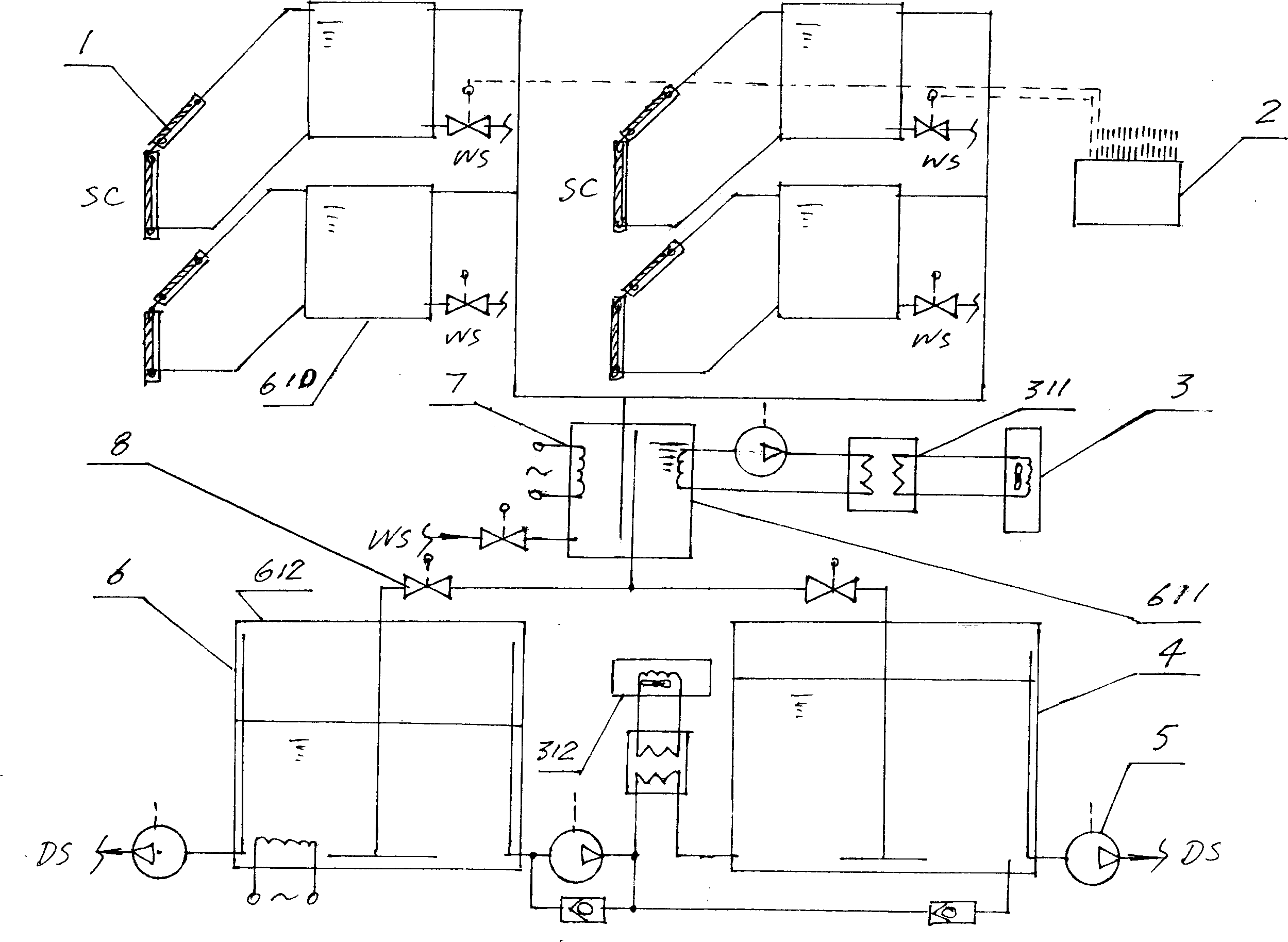

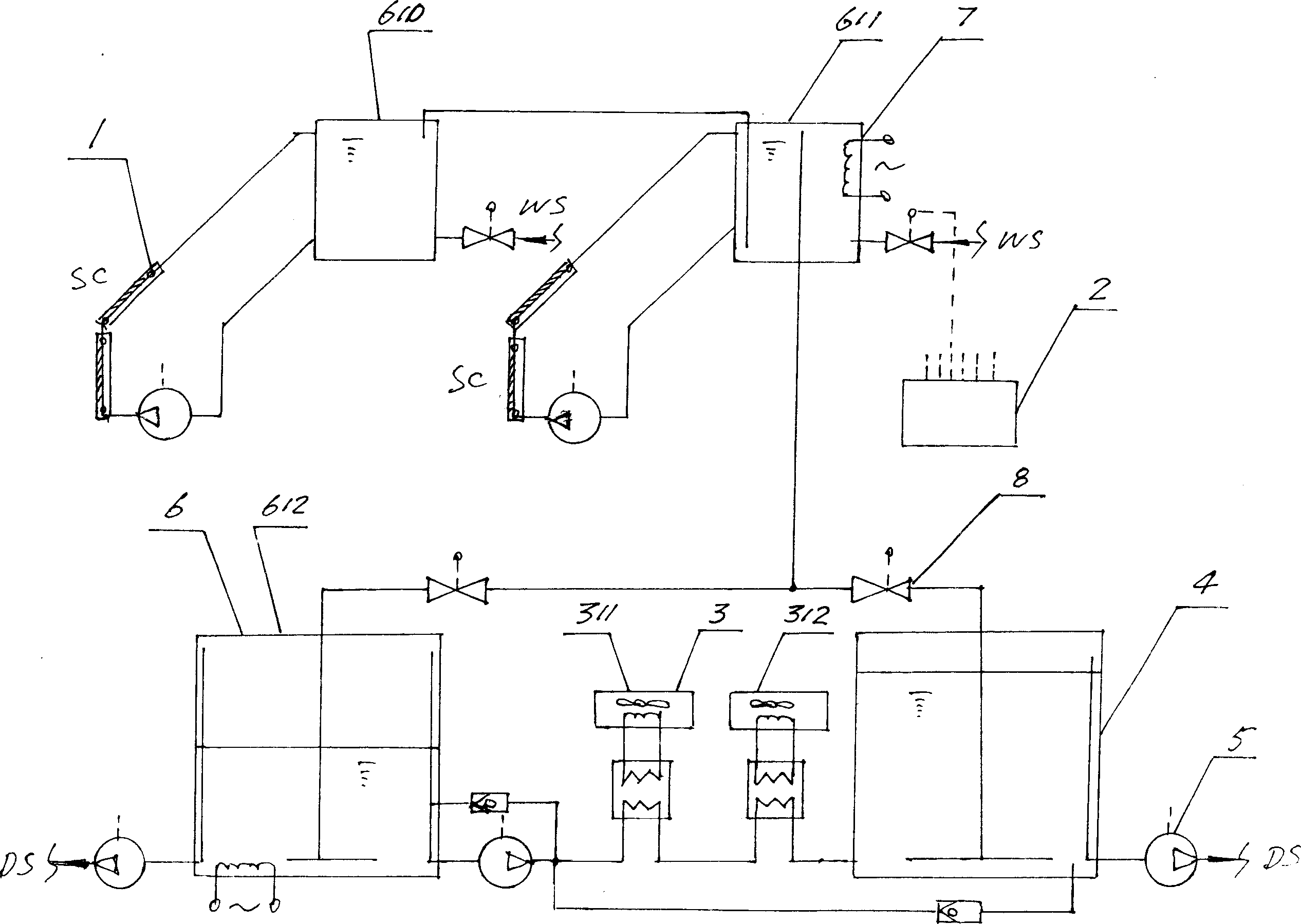

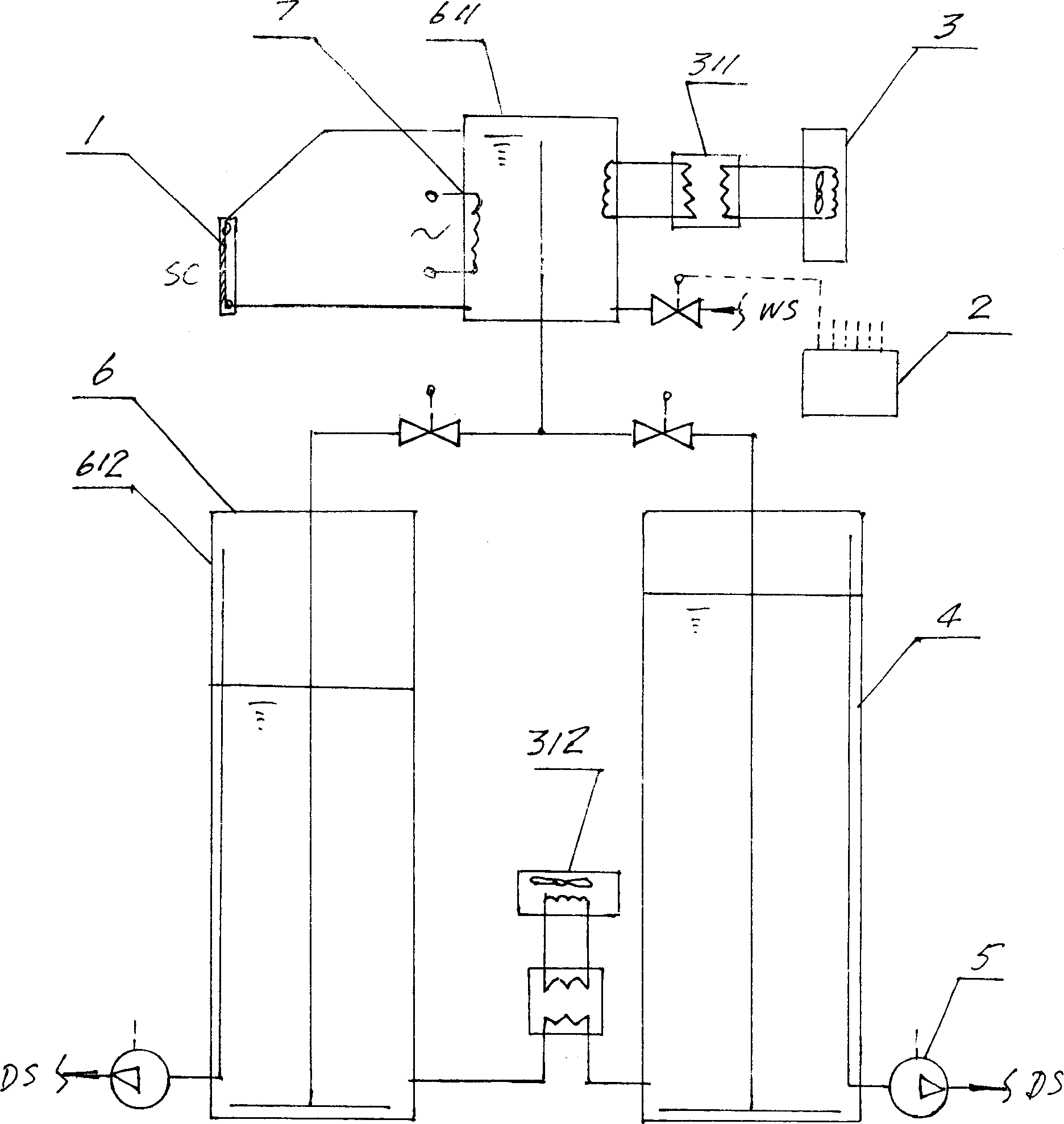

[0024] see figure 1 Shown is a schematic diagram of the device structure of one of the application embodiments of the present invention, including a solar collector 1, a control unit 2, a heat pump 3, a water storage tank 4, a booster pump 5, a heating water tank 6, an electric heating device 7, and an electric control switch Valve 8 etc.

[0025] Among them, the heating water tank 6 is a graded heating water tank, the graded heating water tank is composed of two or more graded heating water tanks 611 and 612, the graded heating water tank 611 is a graded heating confluence hot water tank, and the graded heating water tank 612 It is a graded heating warm water storage tank. The graded heating water tank 611 also includes a graded heating collector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com