Improvement of metal radiating fin radiating speed by nano-carbon tube coating

A technology of carbon nanotubes and heat dissipation speed, which is applied in coatings, metal material coating processes, devices for coating liquids on surfaces, etc. The effect of reducing volume and weight and increasing heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

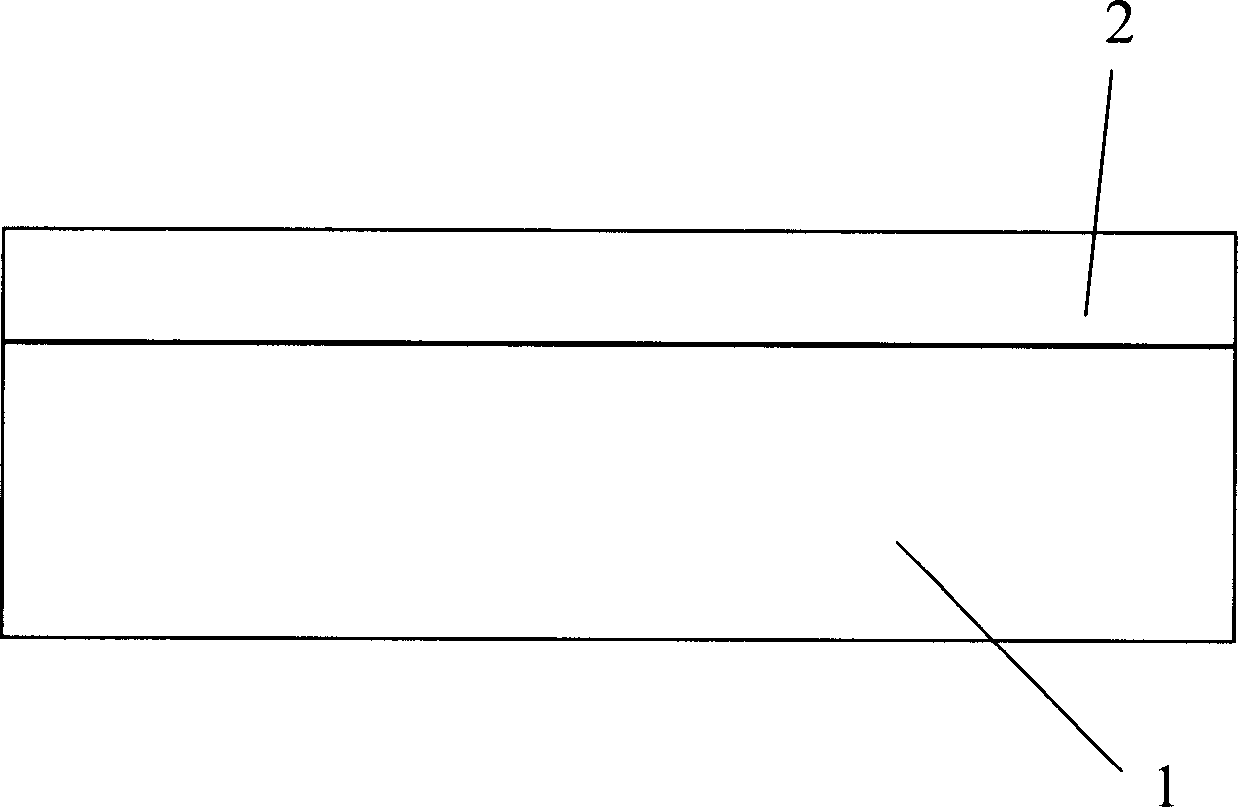

[0008] see figure 1 , a method for improving the heat dissipation speed of a metal radiator with a carbon nanotube (carbon nanotube) coating, comprising the following steps:

[0009] Step 1: Ultrasonic cleaning is performed on the surface of the heat sink 1 of copper or copper alloy;

[0010] The principle of ultrasonic cleaning is that the high-frequency oscillation signal sent by the ultrasonic generator is converted into high-frequency mechanical oscillation by the transducer and propagated to the medium-cleaning solvent. The liquid flows and produces tens of thousands of tiny air bubbles. These bubbles form and grow in the negative pressure zone where the ultrasonic wave travels longitudinally, and close quickly in the positive pressure zone. In this process called "cavitation" effect, the bubble closure can form an instantaneous high pressure of more than 1000 air pressures, and the continuous generation of instantaneous high pressure is like a series of small "explosio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com