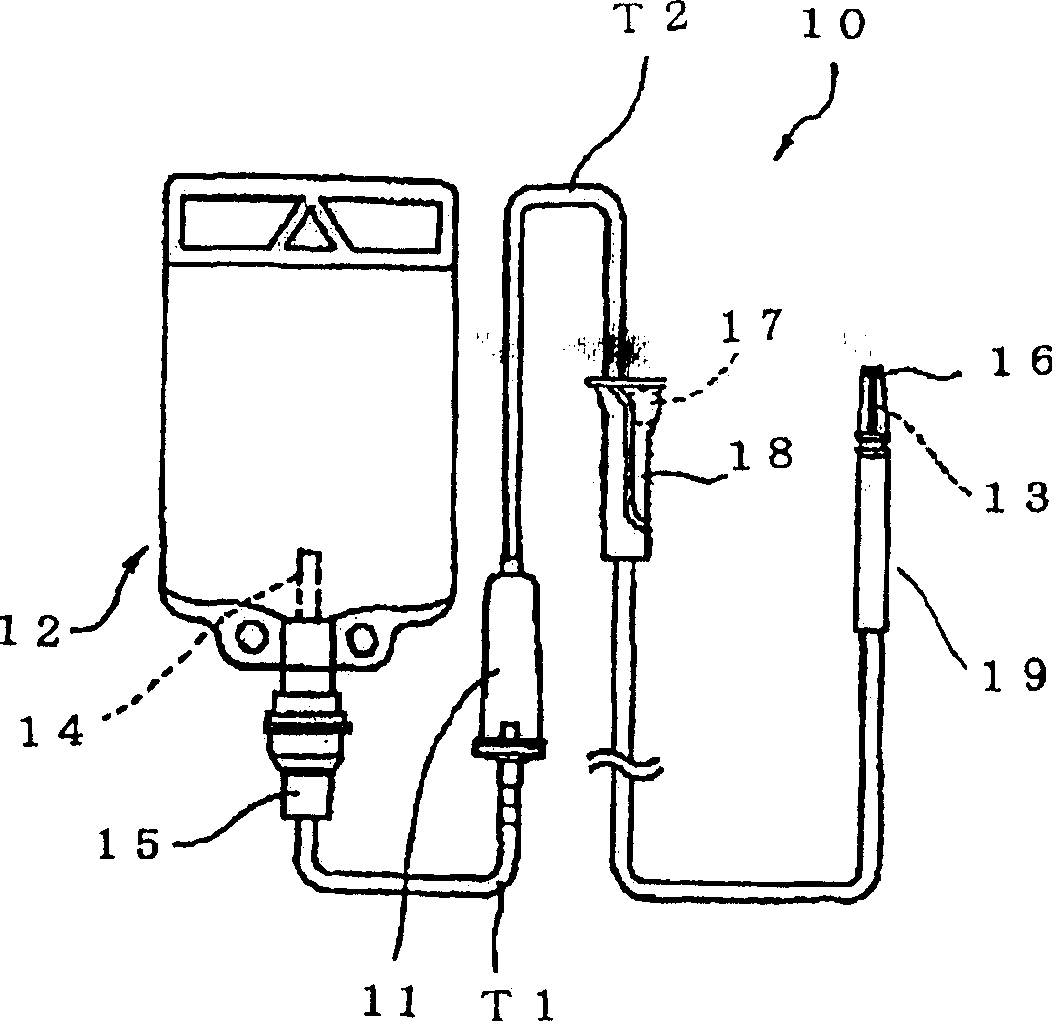

Method for adhering polybutadiene molded article, polybutadiene composite molded article manufactured thereby, medical member, and infusion fluid set

A polybutadiene and bonding method technology, applied in the field of medical components and infusion devices, can solve the problems of lack of polarity of RB, insufficient bonding of polar solvent/polar resin, leakage of pipes and pipe joints, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

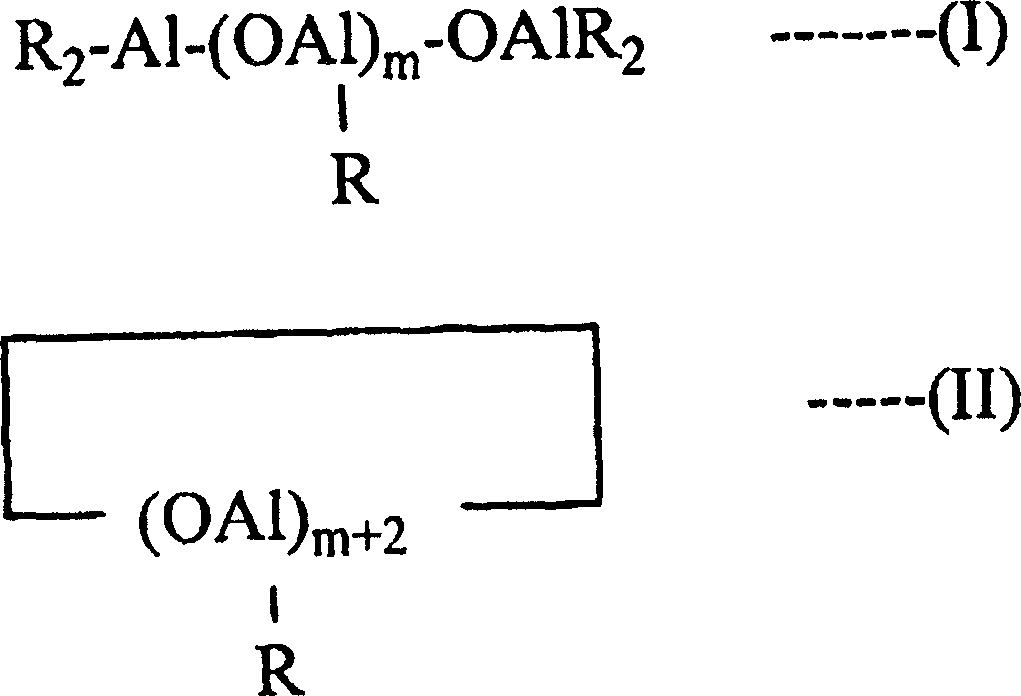

Method used

Image

Examples

preparation example Construction

[0062] Composition preparation and molding

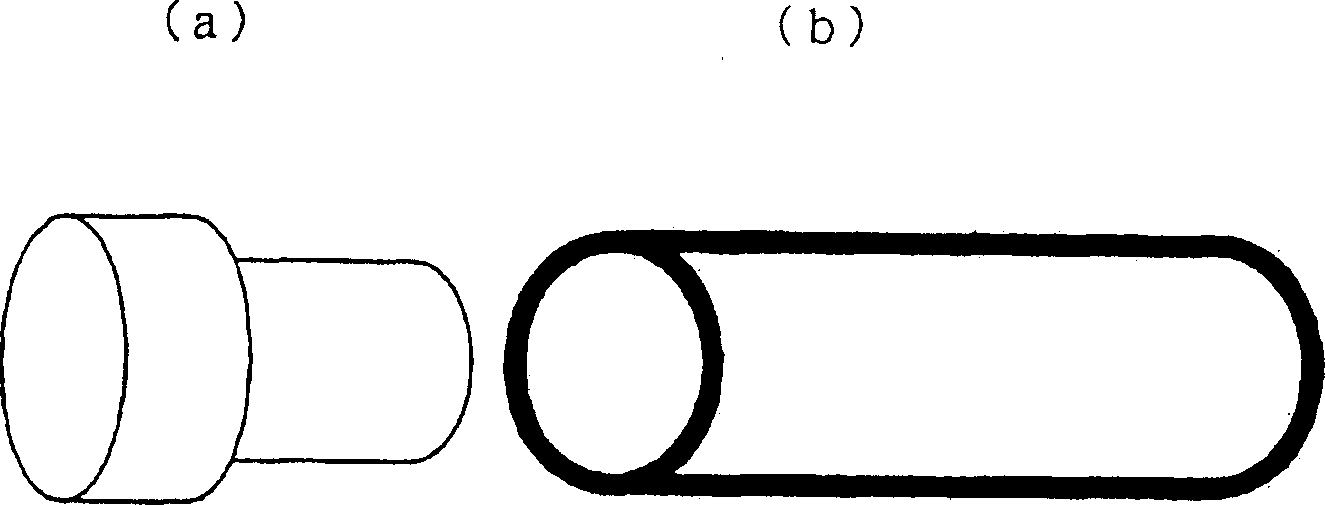

[0063] The composition used for the polybutadiene molded article of the present invention is composed of the above-mentioned component (A) alone or (A) to (B) components, and the above-mentioned additives etc. are added thereto if necessary, softened by heating, kneaded and molded. The kneading and molding are carried out in a temperature range above the softening temperature and melting temperature of syndiotactic 1,2-polybutadiene, in which moldability is good, and processed into homogeneous molded products (medical members such as pipes). Therefore, the molding temperature is preferably about 90 to 170°C. In order to obtain molded products such as pipes and pipe joints, pressure molding, extrusion molding, injection molding, blow molding, special-shaped extrusion molding, T-shaped die film molding, blown film molding, powder slush molding, rotary molding, etc. Molding, etc., forming into pipes, etc., and pipe joints with pipe co...

Embodiment 1

[0186] Embodiment 1, comparative example 1

[0187] Table 1 shows Example 1 and Comparative Example 1. Example 1 is an example in which ozone treatment was performed on a test piece of RB. It can be seen that at 1720cm -1 Absorption of carbonyl groups is present. It can be seen that the contact angle is improved to 32 degrees due to the endowment of polar groups, it is easy to have affinity with cyclohexanone as a polar solvent, and it can be bonded to polycarbonate as a polar resin, and the adhesive force is fully displayed.

Embodiment 2

[0189] Embodiment 2, comparative example 2

[0190] Table 1 shows Example 2 and Comparative Example 2. Example 2 is an example in which ozone treatment was performed on a test piece of RB. It can be seen that at 1720cm -1 Absorption of carbonyl groups is present. It can be seen that the contact angle is improved to 32 degrees due to the addition of polar groups, it is easy to have affinity with cyclohexanone as a polar solvent, and it can be bonded to transparent ABS as a polar resin, and the adhesive force is fully reflected.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com