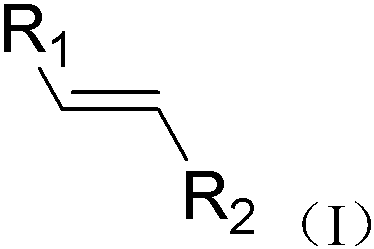

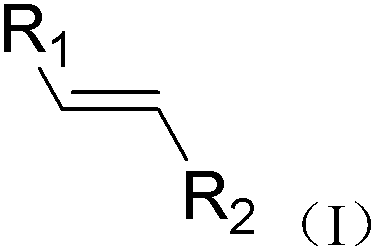

Method of one-pot cascade catalytic copolymerization of ethylene and 1,2-disubstituted polar isomerised olefin and product of the method

A disubstituted, internal olefin technology, applied in chemical instruments and methods, catalysts, hydrocarbons, etc., to achieve the effect of reducing synthesis cost, narrow molecular weight distribution, and high melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

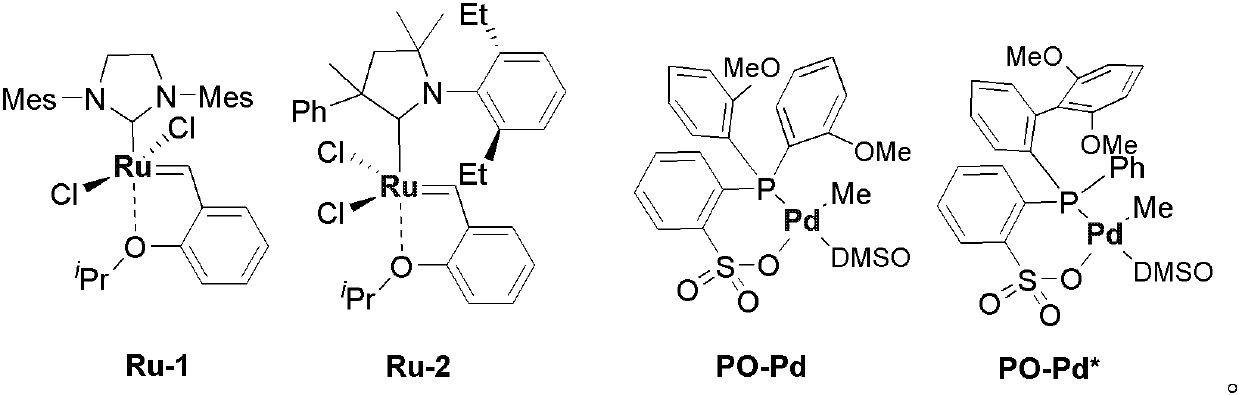

Method used

Image

Examples

Embodiment 1-16

[0069] In the glove box, under a nitrogen atmosphere, 4.5 mmol of the comonomers shown in Table 1 below (i.e. the 1,2-disubstituted polar internal olefin monomer of the present invention) and Optional toluene solvent and its amount (according to the solution concentration of the comonomer in the solvent is 1.5mmol / mL to obtain), and in the reactor, add the catalyst Ru-1 or Ru-2 of 10 μmmol shown in table 1 and 20 μmmol of catalyst PO-Pd or PO-Pd* (the catalyst is preferably dissolved in 0.5 mL of dichloromethane and then injected into the reaction kettle). Then, connect the ethylene gas source pipeline to feed ethylene gas into the reactor, and adjust the ethylene pressure to the reaction pressure specified in Table 1 below. Under magnetic stirring, the reactor was heated to 30°C by heating in a water bath and kept 1h to allow 1,2-disubstituted polar internal olefin monomer to undergo ethenolysis reaction, thereby producing the corresponding ethenolysis monomer product. Next,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com