Polymer blends with improved rheology and improved unnotched impact strength

A technology of polymers and blends, applied in the field of polymer blends, can solve problems such as lack of stability, and achieve the effect of improving temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

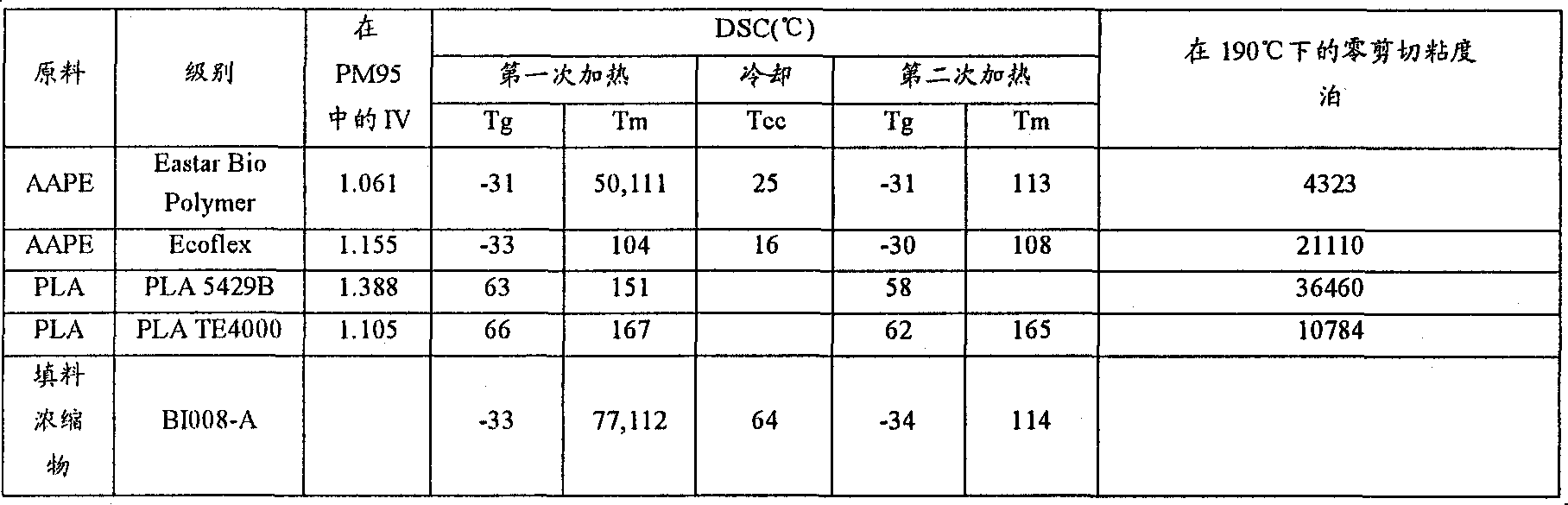

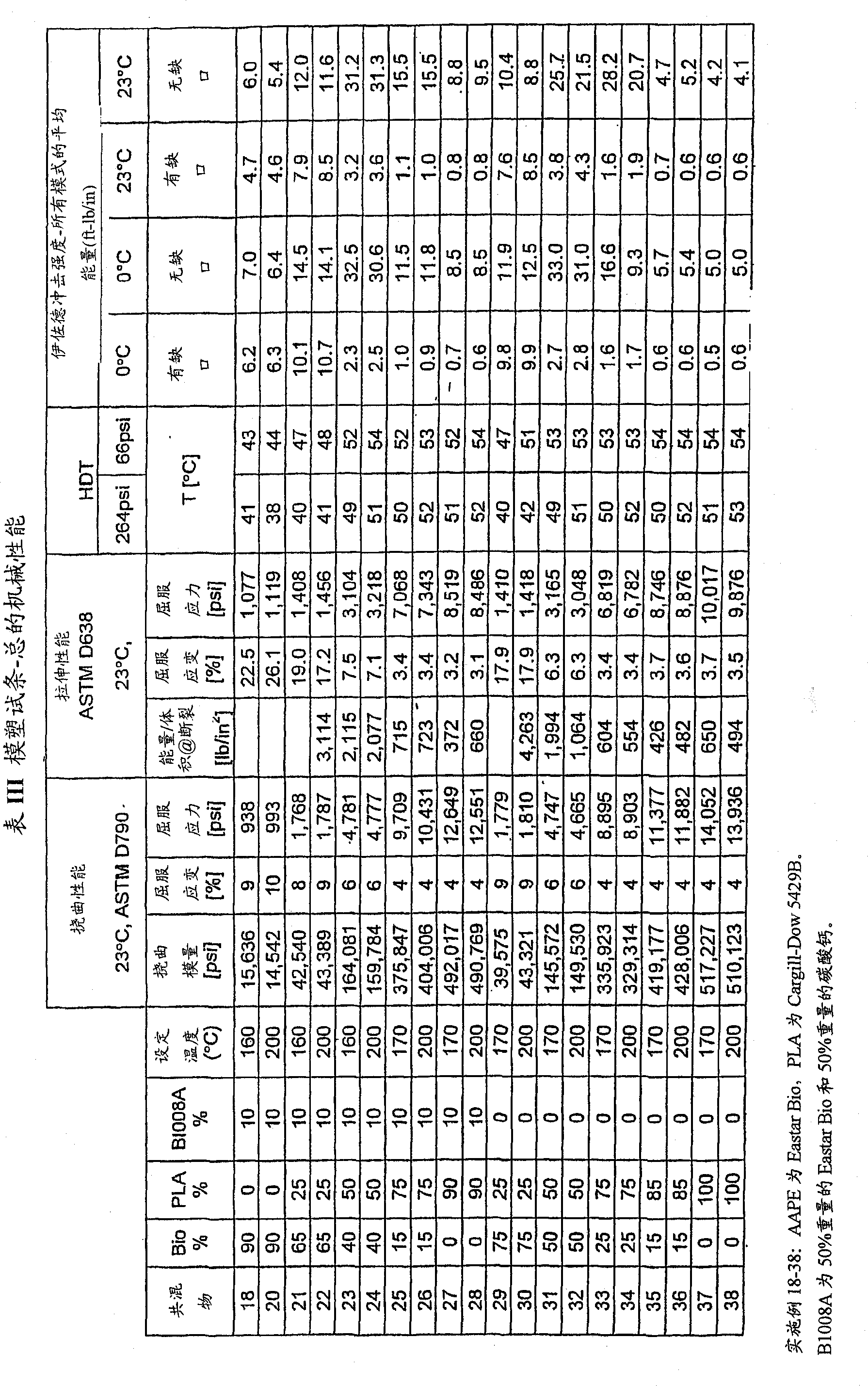

[0298] The polymer blends of the present invention and their preparation, including the preparation of representative polyesters, are further illustrated by the following examples. The glass transition temperature (Tg) of the blend was determined using a TA Instruments 2950 Differential Scanning Calorimeter (DCS) at a scan rate of 20°C / min.

[0299] In the following examples, blends were prepared using the general method: Blends of PLA and AAPE were prepared by compounding in a Sterling 1.25 inch single screw extruder. A typical method is as follows: each raw material is dried overnight at 60-70°C until the moisture content is less than 50ppm. The components were blended in bags and then fed into the barrel of the extruder through the hopper at the desired rate using an AccuRate feeder.

[0300] The prepared blend was molded on a Toyo 90 injection molding machine under the following conditions. These conditions should not be considered ideal conditions, but are typical condi...

Embodiment 7-12

[0335] Examples 7-12: AAPE is Eastar Bio, PLA is UnitikaTE4000.

[0336] Examples 13-17: AAPE is ECOFLEX, PLA is Cargill-Dow 5429B.

[0337] Eastar Bio polymer is a composition comprising 45 mole percent terephthalic acid, 55 mole percent adipic acid and 100 mole percent 1,4-butanediol, wherein the total mole percent of diols is equal to 100 mole percent, The total mole percent of diacids equals 100% moles; B1008A is 50% by weight Eastar Bio and 50% by weight calcium carbonate.

[0338]

[0339] Based on the above data it is clear that the composition of interest here is unique and depends on the ratio of the AAPE / PLA blend, not on the nature of the PLA or AAPE itself.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com