Composite hydrogen storage material contg. magnesium-transition metals oxides, prepn. method and application thereof

A technology of transition metals and hydrogen storage materials, applied in the fields of alkali metals/alkaline earth metals/beryllium/magnesium hydrides, chemical instruments and methods, and other chemical processes, which can solve the problems of reduced hydrogen absorption, expensive nickel, and increased material costs, etc. problem, achieve the effect of lowering the hydrogen storage temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

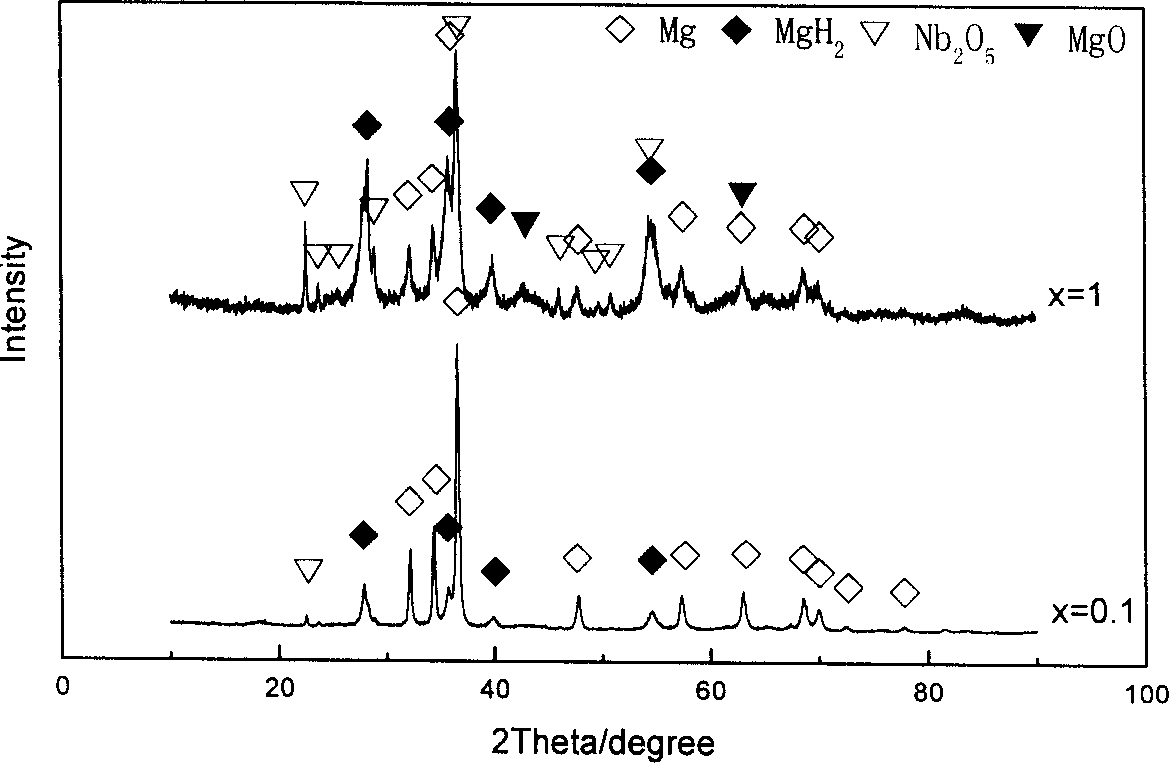

[0031] Example 1: Mg+xmol.%Nb 2 o 5 Preparation and Kinetic Properties of Composite Hydrogen Storage Materials

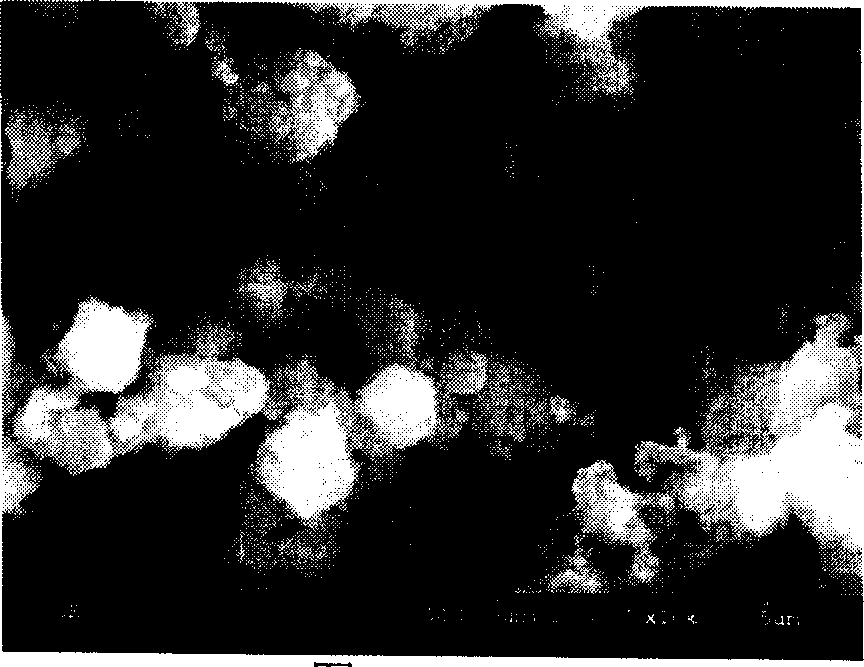

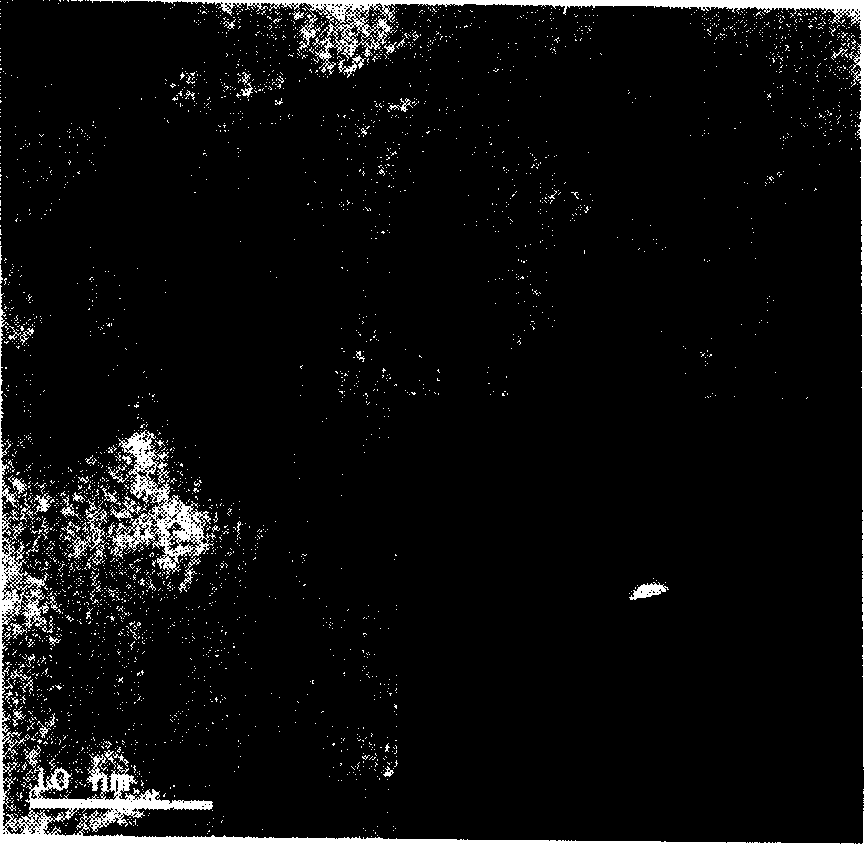

[0032] Magnesium powder (purity, 99%, 100-200 mesh) and Nb 2 o 5 (purity, 99%, 100-200 mesh) according to Mg+xmol.%Nb 2 o 5(x=0.05, 0.1, 0.2, 0.5, 1, 2) stoichiometric proportioning. Prepared by high-energy ball milling method, the ratio of ball to material is 20:1, the sample tank is evacuated, then filled with hydrogen, repeat 3 times to remove the air in the tank, and finally filled with 0.2MPa high-purity hydrogen. Control the rotating speed to 500r / min, after every 15min rotation, let it stand still for 5min, every 30min of ball milling, fill with hydrogen once to ensure the hydrogen pressure is 0.2MPa, and the desired sample can be obtained after 30h of ball milling. All the above operations were performed in a vacuum glove box. figure 1 Mg+xmol.%Nb 2 o 5 (x=0.2, 1) The X-ray diffraction pattern (XRD) of the composite hydrogen storage material after b...

Embodiment 2

[0034] Embodiment 2: Mg+xmol.%Cr 2 o 3 Preparation and Kinetic Properties of Composite Hydrogen Storage Materials

[0035] The preparation method of the composite material is the same as that of Example 1. Magnesium powder (purity, 99%, 100-200 mesh) and Cr 2 o 3 (purity, 99%, 100-200 mesh) according to x=0.05,0.1,0.2,0.5,1,2 stoichiometric proportioning. Prepared by high-energy ball milling method, the ratio of ball to material is 30:1, the sample tank is evacuated, then filled with hydrogen, repeat 3 times to remove the air in the tank, and finally filled with 0.2MPa high-purity hydrogen. Control the rotation speed to 450r / min, after each rotation for 15min, let it stand still for 5min, and fill it with hydrogen once every 30min of ball milling to ensure that the hydrogen pressure is 0.2MPa, and the desired sample can be obtained after 30h of ball milling. The structure and surface topography of the composite material are also similar to Example 1, that is, the XRD, SEM...

Embodiment 3

[0036] Embodiment 3: Mg+xmol.% Fe 3 o 4 Preparation and Kinetic Properties of Composite Hydrogen Storage Materials

[0037] The preparation method of the composite material is the same as that of Example 1. Magnesium powder (purity, 99%, 100-200 mesh) and Fe 3 o 4 (purity, 99%, 100-200 mesh) according to x=0.05,0.1,0.2,0.5,1,2 stoichiometric proportioning. Prepared by high-energy ball milling method, the ratio of ball to material is 40:1, the sample tank is evacuated, then filled with hydrogen, repeat 3 times to remove the air in the tank, and finally filled with 0.2MPa high-purity hydrogen. Control the rotation speed to 400r / min, after each rotation for 15 minutes, let it stand still for 5 minutes, and fill with hydrogen once every 30 minutes of ball milling to ensure that the hydrogen pressure is 0.2MPa, and the desired sample can be obtained after 30 hours of ball milling. The structure and surface topography of the composite material are also similar to Example 1, tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com