Method for improving freezing resistance of lactic acid bacteria in freezing sour flour dough using glutathione

A technology of glutathione and sourdough, applied in the direction of dough processing, pre-baked dough processing, application, etc., can solve the problems of short shelf life of sourdough and unstable quality of the final product, so as to save the fermentation stage and improve the resistance of the sourdough. The ability to freeze, the effect of slowing down the peroxidation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

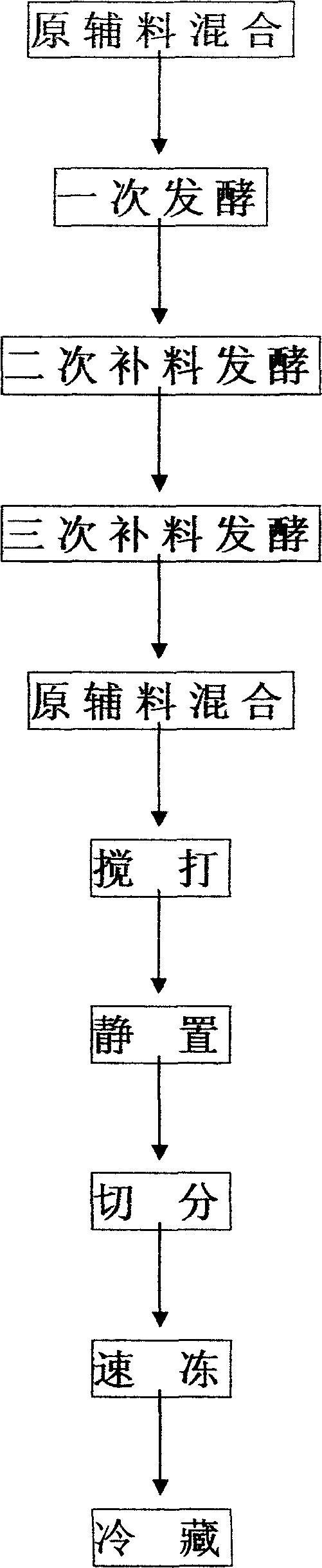

Image

Examples

Embodiment 1

[0019] The present invention uses glutathione to improve the method for the frost resistance of lactic acid bacteria in sourdough, adopts the following process steps: the formula ratio is counted by the number of parts:

[0020] Sourdough starter: primary fermentation: take 48 parts of flour, 48 parts of water, and 0.1 part of reduced glutathione, mix evenly, and place it at 29°C to ferment for 25 hours; secondary fermentation: in the above fermented sourdough Add 48 parts of flour and 48 parts of water, mix evenly, and place it at 29°C to ferment for 49 hours; three feeding fermentations: add 48 parts of flour and 48 parts of water to the above-mentioned fermented sourdough, mix evenly, and place it at 29°C Ferment until 73 hours to become a semi-solid sourdough starter; bread dough formation: Take 45 parts of flour, 20 parts of semi-solid sourdough starter, 23 parts of water, and 1.0 part of salt, mix well, add to the mixing tank and beat for 10 minutes , Knead and form a do...

Embodiment 2

[0021] Embodiment two: the present invention adopts following processing steps:

[0022] Sour dough starter: primary fermentation: take 49 parts of flour, 49 parts of water, and 0.2 parts of reduced glutathione, mix evenly, and place it at 30°C to ferment for 24 hours; secondary fermentation: in the above fermented sourdough Add 49 parts of flour and 49 parts of water, mix evenly, and place it at 30°C to ferment for 48 hours; three feeding fermentations: add 49 parts of flour and 49 parts of water to the above-mentioned fermented sourdough, mix evenly, place at 30°C Ferment until 72 hours to become a semi-solid sourdough starter; bread dough formation: Take 48 parts of flour, 23 parts of semi-solid sourdough starter, 28 parts of water, and 1.5 parts of salt, mix well, add to the mixing tank and beat for 12 minutes , knead and form a dough; take out the above dough and let it stand for 12 minutes, and then cut it as needed; quick freezing: put the cut dough at -39°C for 1.3 hou...

Embodiment 3

[0023] Embodiment three: the present invention adopts following processing steps:

[0024] Sour dough starter: primary fermentation: take 50 parts of flour, 50 parts of water, and 0.3 parts of reduced glutathione, mix evenly, and place it at 31°C to ferment for 23 hours; secondary fermentation: in the above fermented sourdough Add 50 parts of flour and 50 parts of water, mix evenly, and place it at 31°C to ferment for 47 hours; three feeding fermentations: add 50 parts of flour and 50 parts of water to the above-mentioned fermented sourdough, mix evenly, place at 31°C Ferment for 71 hours to become a semi-solid sourdough starter; bread dough formation: Take 50 parts of flour, 25 parts of semi-solid sourdough starter, 34 parts of water, and 2.0 parts of salt, mix well, add to the mixing tank and beat for 15 minutes, Knead into a dough; take out the above dough and let it stand for 15 minutes, and cut it as needed; quick freezing: put the cut dough at -40℃ for quick freezing for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com