Method for arch dam fast construction by externally mixing MgO slightly expanded concrete

A micro-expansion concrete and concrete technology, applied in the field of construction, can solve the problems such as the limitation of promotion and application, the lack of specifications for design and construction, and achieve a wide range of adaptation conditions and scope, significant economic and social benefits, and improve compensation and crack resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

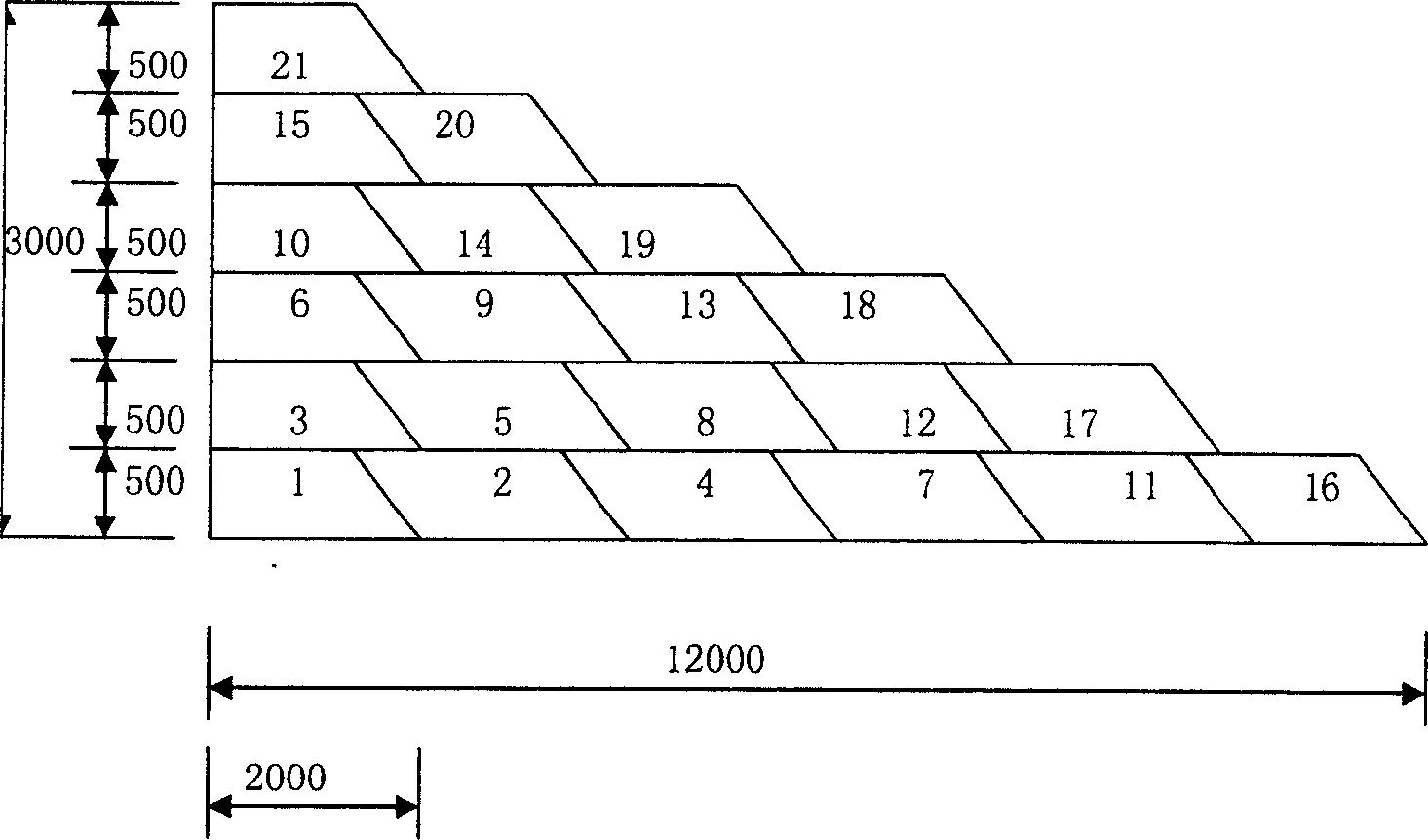

[0017] Example 1: 3m layer

[0018] Preparation of lightly calcined MgO: calcining magnesite with MgO content > 44% to 1100±50°C, holding time 0.5h, activity index 240±20s, particle size 180-250 mesh.

[0019] (1) Batching: batching according to cement 119Kg: sand 538Kg: extra large stone 551Kg: big stone 551Kg: medium stone 340Kg: small stone 340Kg: fly ash 51Kg: MgO9.35Kg: water reducing agent 1.7Kg: water 85Kg;

[0020] (2) mixing:

[0021] The MgO feeding control adopts the "wet mixing" method to add, and the weighing error is less than 1%. A set of MgO automatic stirring device is installed. This device is mainly arranged in the water bucket. When the MgO is fed and weighed by the screw machine, it is automatically added Into the weighed water tank, the mixer starts to stir at this time. The admixture (water reducer) is adjusted to a suspension by adding water in a conventional proportion, weighed and poured into the bucket. Stir together with MgO for 60s and then mix ...

Embodiment 2

[0027] The preparation of lightly burned MgO: with embodiment 1

[0028] (1) Batching: According to cement 119Kg: sand 538Kg: extra large stone 551Kg: big stone 551Kg: medium stone 340Kg: small stone 340Kg: fly ash 51Kg: MgO6.8Kg: water reducing agent 1.7Kg: water 85Kg;

[0029] (2) mixing:

[0030] The MgO feeding control adopts the "wet mixing" method to add, and the weighing error is less than 1%. A set of MgO automatic stirring device is installed. This device is mainly arranged in the water bucket. When the MgO is fed and weighed by the screw machine, it is automatically added Into the weighed water tank, the mixer starts to stir at this time. The admixture (water reducer) is adjusted to a suspension by adding water in a conventional proportion, weighed and poured into the bucket. Stir together with MgO for 60s and then mix into a homogeneous suspension.

[0031] Put the weighed extra large stone, large stone, medium stone, small stone, sand, ordinary silicon 525 cemen...

Embodiment 3

[0036] The preparation of lightly burned MgO: with embodiment 1

[0037] (1) Batching: According to cement 119Kg: sand 538Kg: extra large stone 551Kg: big stone 551Kg: medium stone 340Kg: small stone 340Kg: fly ash 51Kg: MgO10.2Kg: water reducing agent 1.7Kg: water 85Kg;

[0038] (2) mixing:

[0039]The MgO feeding control adopts the "wet mixing" method to add, and the weighing error is less than 1%. A set of MgO automatic stirring device is installed. This device is mainly arranged in the water bucket. When the MgO is fed and weighed by the screw machine, it is automatically added Into the weighed water tank, the mixer starts to stir at this time. The admixture (water reducer) is adjusted to a suspension by adding water in a conventional proportion, weighed and poured into the bucket. Stir together with MgO for 60s and then mix into a homogeneous suspension.

[0040] Put the weighed extra large stone, large stone, medium stone, small stone, sand, ordinary silicon 525 cemen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com