Dye based circularly polarizing film for organic light emitting diodes

A technology of light-emitting diodes and circular polarizers, which is applied to the materials of organic semiconductor devices, luminescent materials, organic semiconductor devices, etc., can solve the problems of reducing external quantum efficiency, improve external luminous efficiency, increase brightness, and reduce power consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

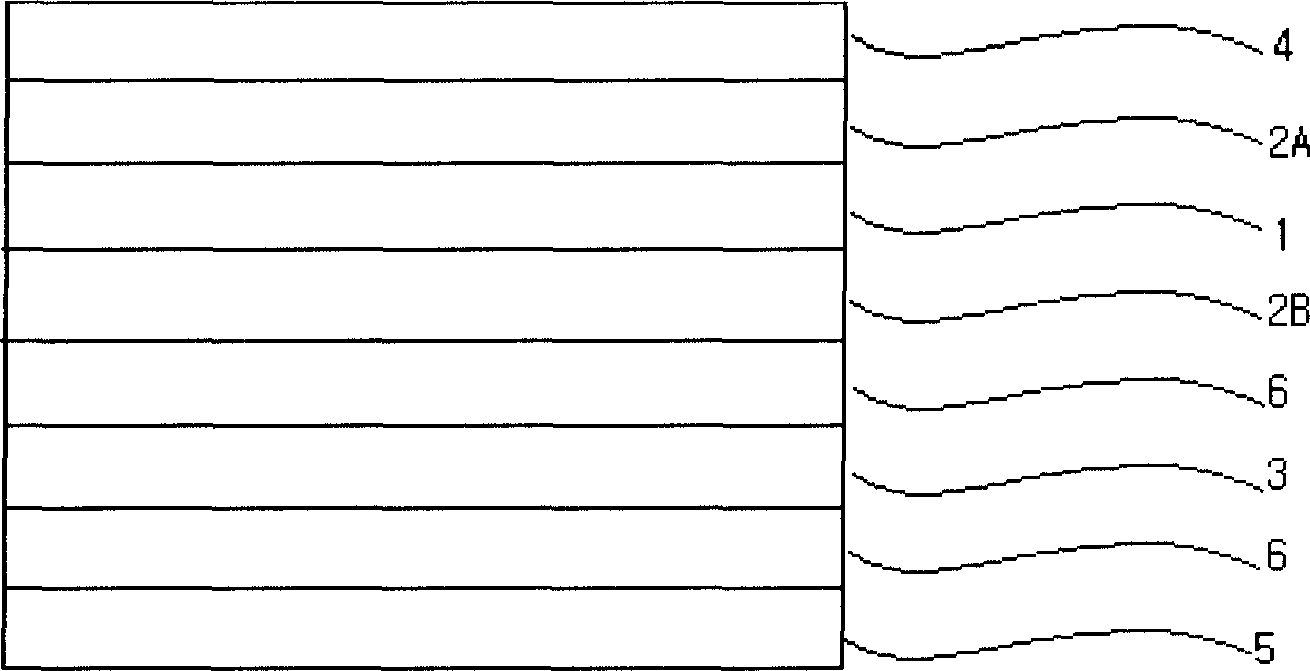

[0060] The circular polarizer of Example 1 was manufactured through the following steps.

[0061] (1) washing

[0062] Add 20000 g of normal temperature water into a 25000 ml cleaning tank, and fully wash polyvinyl alcohol (PVA) (product of Kuraray Company, trade name VF-P#7500) with a width of 310 mm for two minutes.

[0063] (2) swelling

[0064] Add 24000g of water into the swelling tank of 30000ml and heat up to 35 degrees, and place the PVA film through the above (1) water washing process for 1 minute and 30 seconds to swell.

[0065] (3) Dichroic dye (polarizer) dyeing

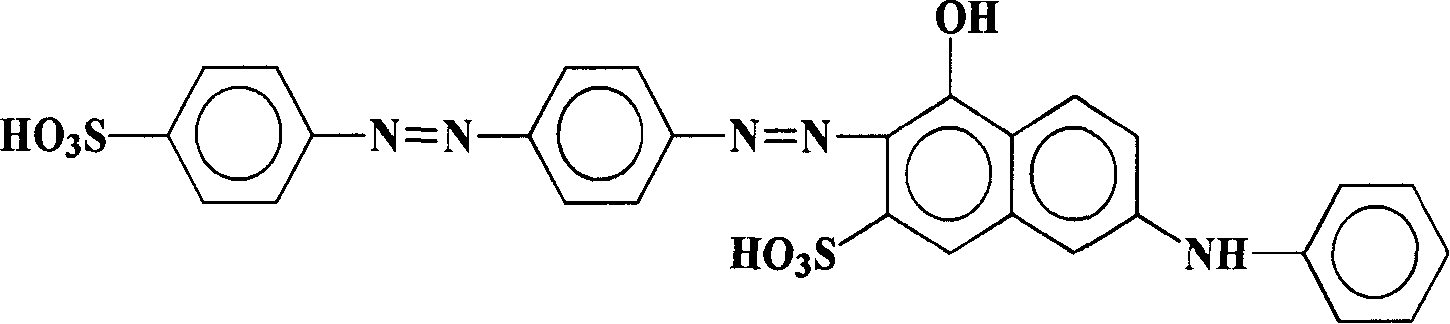

[0066] In the dissolving tank of 20000ml, add 265g of the dyestuff of chemical formula 1 and 20g of chemical formula 2 of the above-mentioned group A, and heat to make it dissolve completely. The solution was transferred to a 90000ml dyeing tank, and 50000g of warm water was added. Here, 700 g of sodium sulfate was added to dissolve it completely, and then cooled to 42 degrees. The membrane swollen ...

Embodiment 2

[0092] With the dichroic dye 260g of the chemical formula 4 of group B, this single dyestuff replaces the dichroic dye in the dyeing process (3) of embodiment 1, i.e. the dichroic dye 265g of the chemical formula 1 of group A and the dichroic dye of the chemical formula 2 Except for 20 g of dichroic dyes, steps (1) to (14) were performed using the same method as in Example 1 to manufacture a circular polarizing plate.

[0093] The same method as in Example 1 was used for the manufactured polarizer, and its optical characteristics and power consumption were measured.

Embodiment 3

[0095] Replace the dichroic dye in the dyeing process (3) of embodiment 1 with the mixture of the dichroic dye 255g of chemical formula 4 of group B and the dyestuff 4.5g of chemical formula 6 of group C, i.e. the dichroic dye of chemical formula 1 of group A Except for 265 g of the neutral dye and 20 g of the dichroic dye of the chemical formula 2, the same method as in Example 1 was used to perform steps (1) to (14) to manufacture a circular polarizer.

[0096] The same method as in Example 1 was used for the manufactured polarizer, and its optical characteristics and power consumption were measured.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com