Dye compositions for anisotropic dye films, anisotropic dye films and polarizing elements

A dye composition, anisotropic technology, applied in the direction of polarizing elements, azo dyes, organic dyes, etc., can solve the problem of poor dichroism and achieve good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

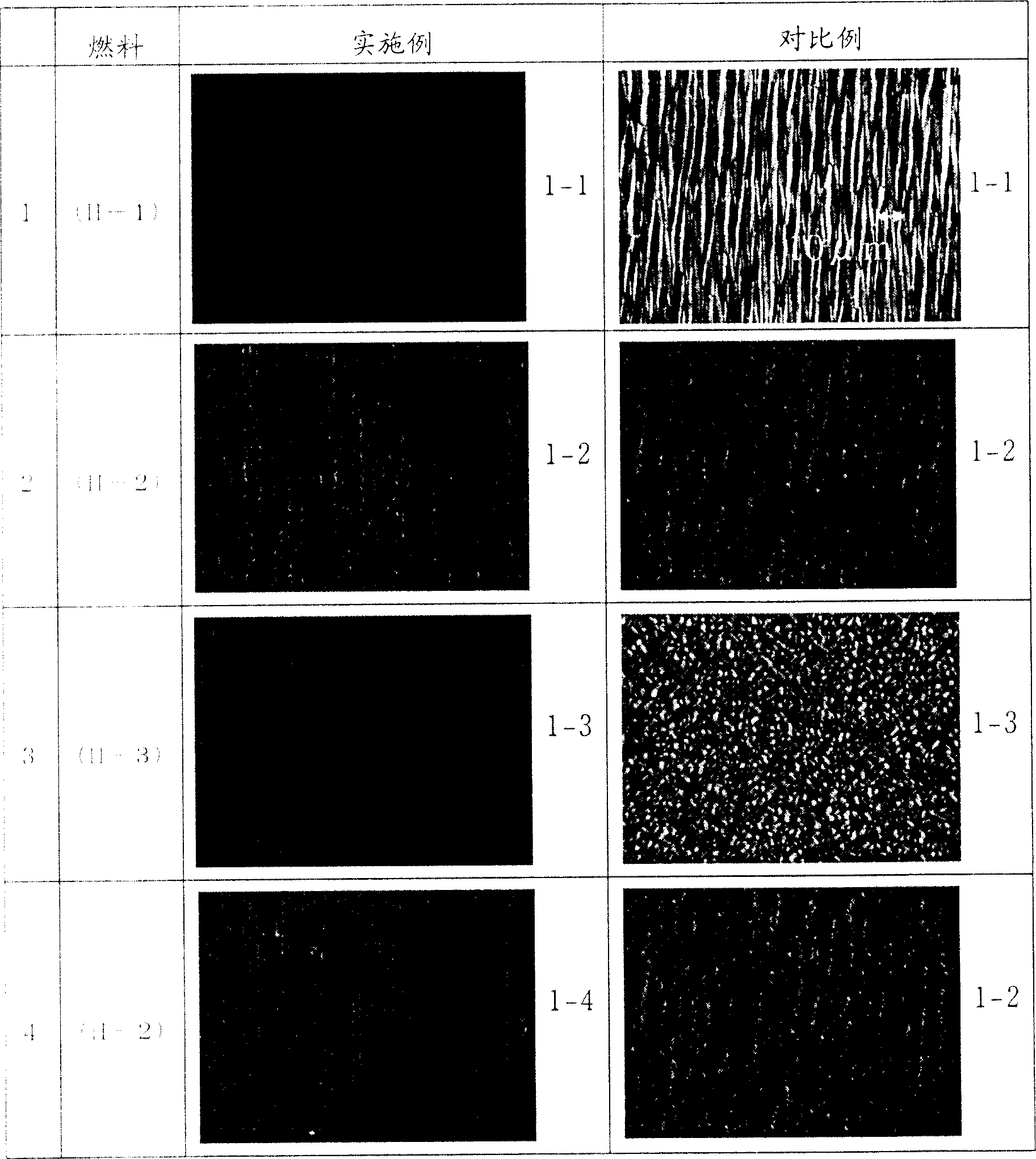

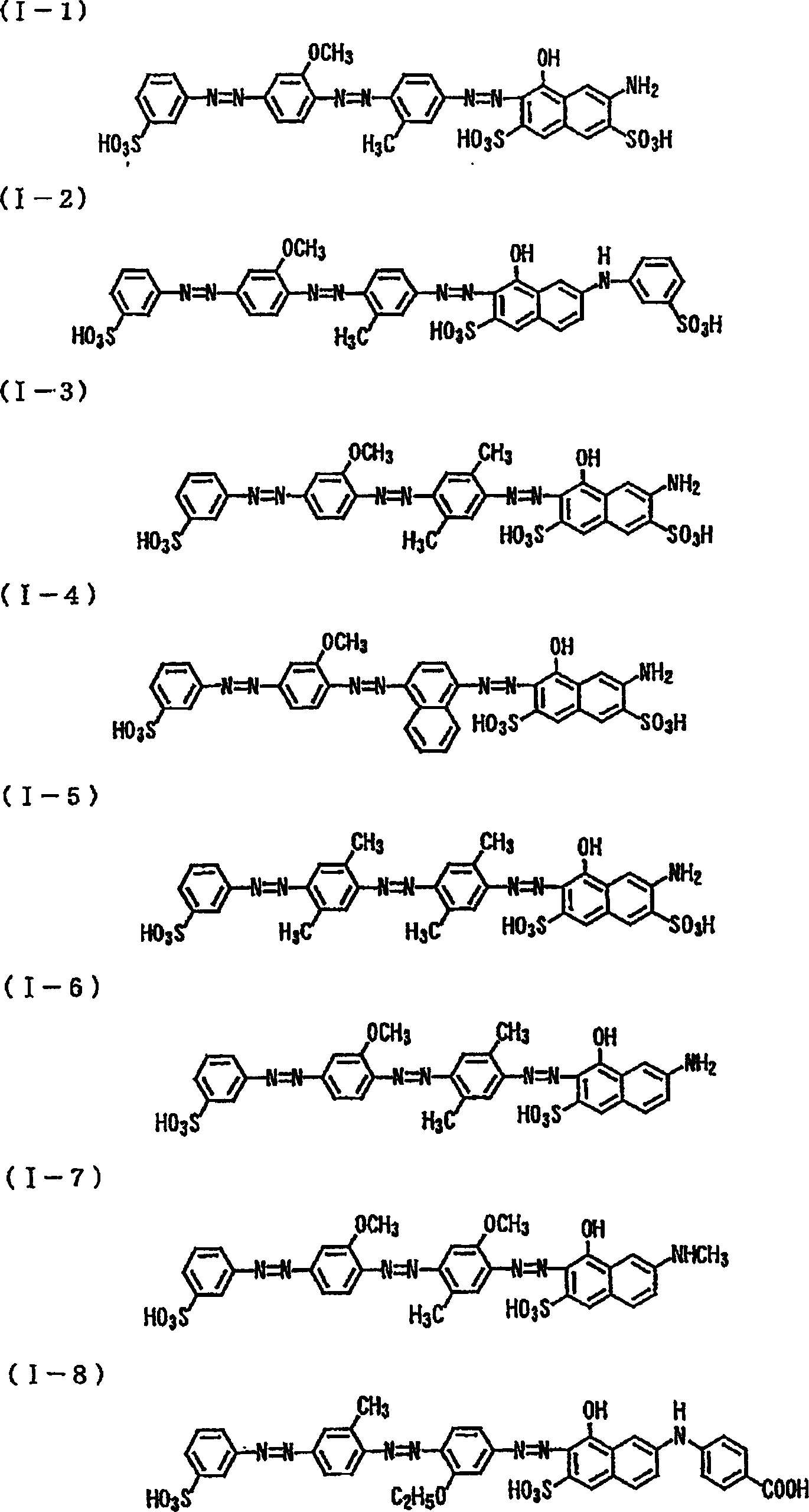

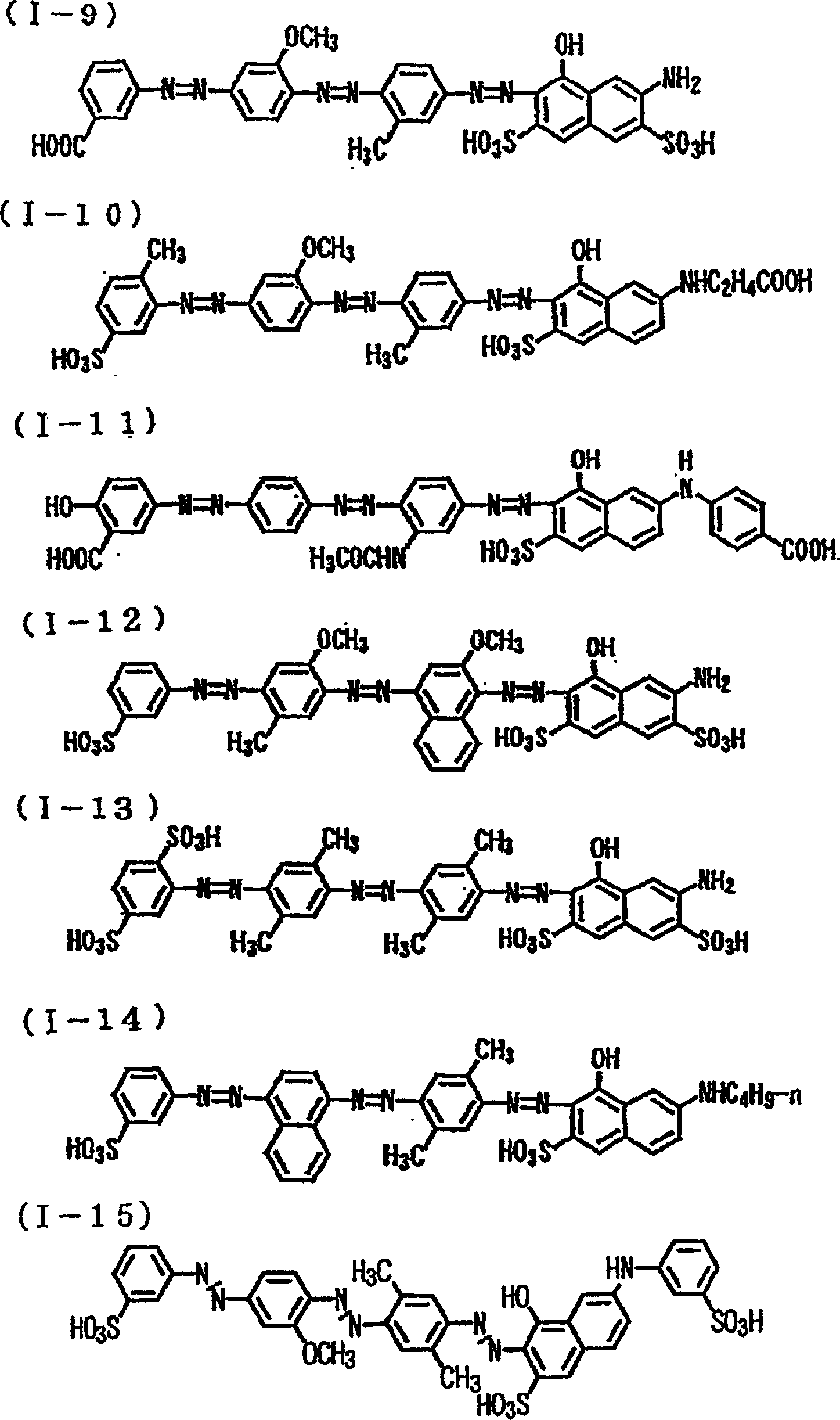

[0152] 5 parts of dye (II-1) and 2.5 parts of L-(+) lysine monohydrochloride (number of basic groups: 2; number of acidic groups: 1) (manufactured by Tokyo Chemical Industry Co., Ltd.) were added to In 92.5 parts of water (the molar ratio of dyestuff and L-(+) lysine monohydrochloride is 1: 1), stir and dissolve, then filter, obtain the dyestuff for anisotropic dyestuff film of the present invention that pH is 7 combination. Form the glass substrate (75mm * 25mm, thickness: 1.1mm) of polyimide alignment film with spin-coating method on the surface, have the polyimide alignment film of the polyimide film of about 800 Ȧ in advance with cloth. rubbing treatment), the above-mentioned dye composition for anisotropic dye film was coated with a coater (produced by Imoto Manufacturing Co., Ltd.) with a gap of 10 μm, followed by natural drying to obtain an anisotropic dye film with a thickness of about 0.4 μm .

[0153] Photographs of defects in the resulting anisotropic dye film are...

Embodiment 1-2

[0156] 14 parts of above-exemplified dyes (II-2) and 3.1 parts of L-(+) lysine monohydrochloride (number of basic groups: 2; number of acid groups: 1) (by Tokyo Chemical Industry Co., Ltd. production) was added to 82.9 parts of water (the molar ratio of dye to L-(+) lysine monohydrochloride was 1:1), stirred and dissolved, followed by filtration to obtain the anisotropic compound of the present invention with a pH of 7. Dye composition for dye film. The dye composition for an anisotropic dye film was coated on the same substrate as in Example 1-1 under the same conditions to obtain an anisotropic dye film having a thickness of about 0.9 μm.

[0157] Photographs of defects in the resulting anisotropic dye film are shown in figure 1 middle. And, the maximum absorption wavelength (λ max ) and its dichroic ratio (D) are shown in Table 1.

[0158] The anisotropic dye film obtained in this example has very few defects, the film has a high dichroic ratio (light absorption anisotr...

Embodiment 1-3

[0160] With 15 parts of above-exemplified dyes (II-3) and 3.3 parts of L-(+) lysine monohydrochloride (number of basic groups: 2; number of acidic groups: 1) (by Tokyo Chemical Industry Co., Ltd. production) was added to 81.7 parts of water (the molar ratio of dye to L-(+) lysine monohydrochloride was 1:1), stirred and dissolved, followed by filtration to obtain the anisotropic anisotropic compound of the present invention with a pH of 7. Dye composition for dye film. The dye composition for an anisotropic dye film was coated on the same substrate as in Example 1-1 under the same conditions to obtain an anisotropic dye film having a thickness of about 0.9 μm.

[0161] Photographs of defects in the resulting anisotropic dye film are shown in figure 1 middle. And, the maximum absorption wavelength (λ max ) and its dichroic ratio (D) are shown in Table 1.

[0162] The anisotropic dye film obtained in this example has very few defects, the film has a high dichroic ratio (light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com