Device for preparing metal ultrafine powder and its method

An ultra-fine powder and ultra-fine powder technology, applied in the field of metallurgy, can solve the problems of narrow powder particle size distribution, large energy consumption, large powder particle size, etc., and achieve the effect of reducing the probability of agglomeration, improving the uniformity and increasing the impulse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

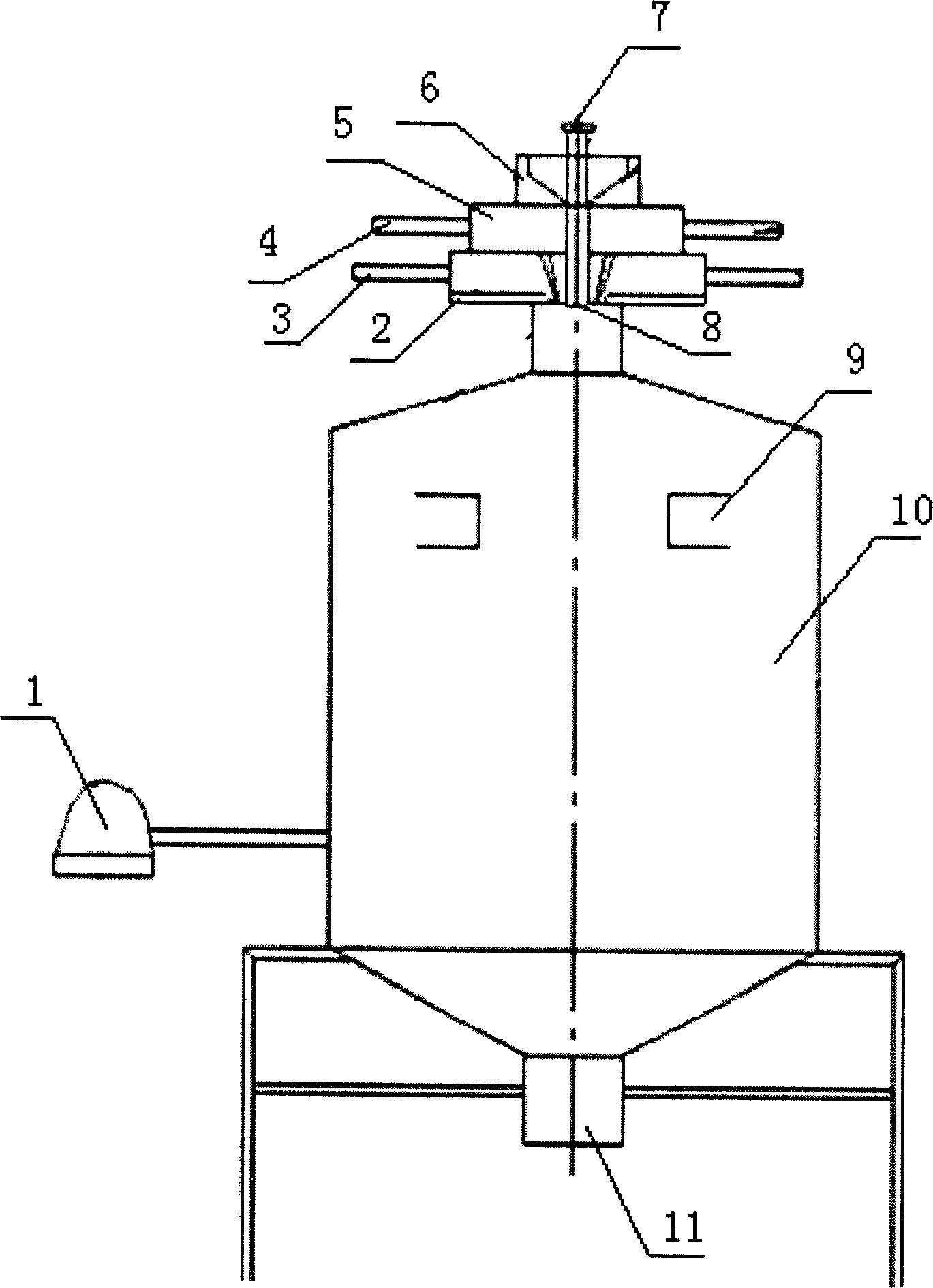

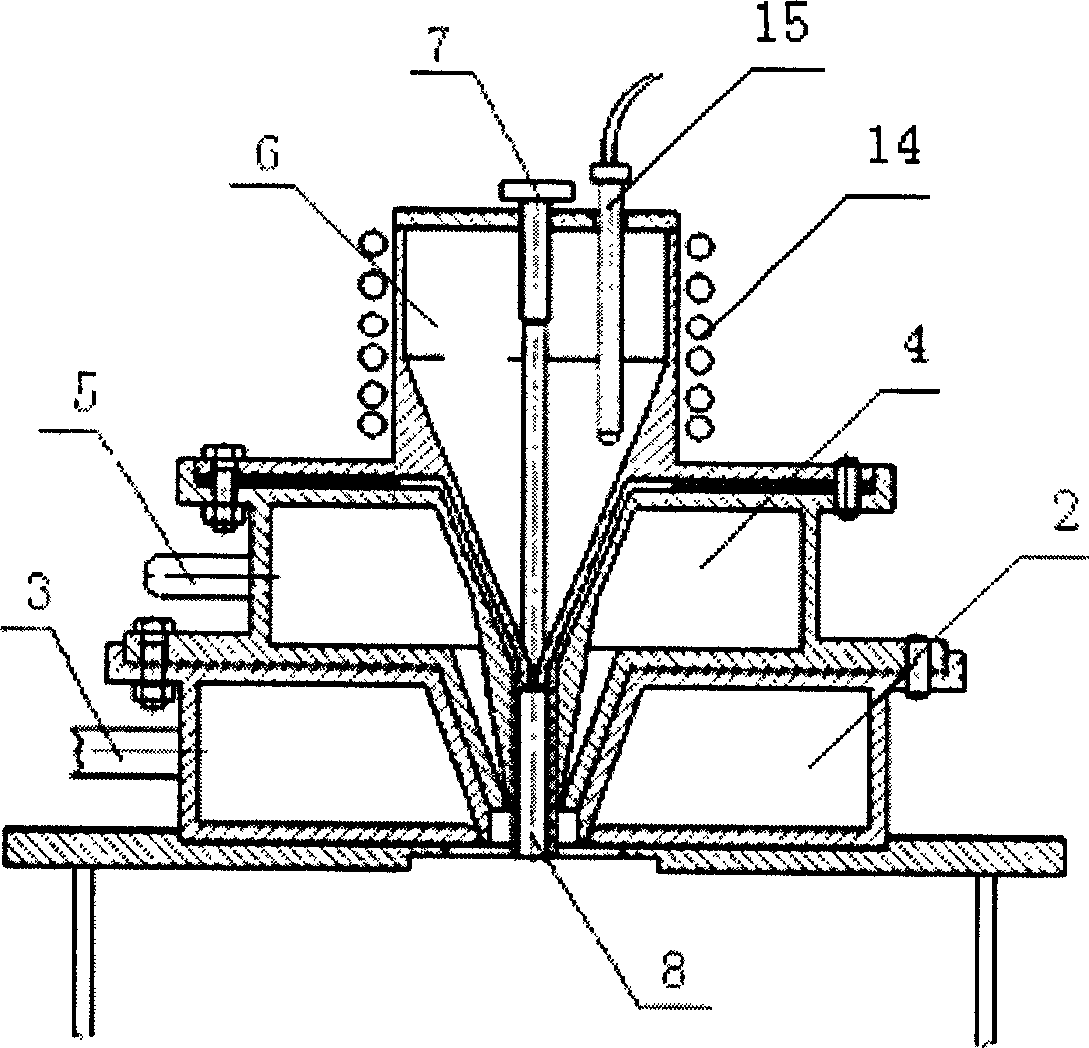

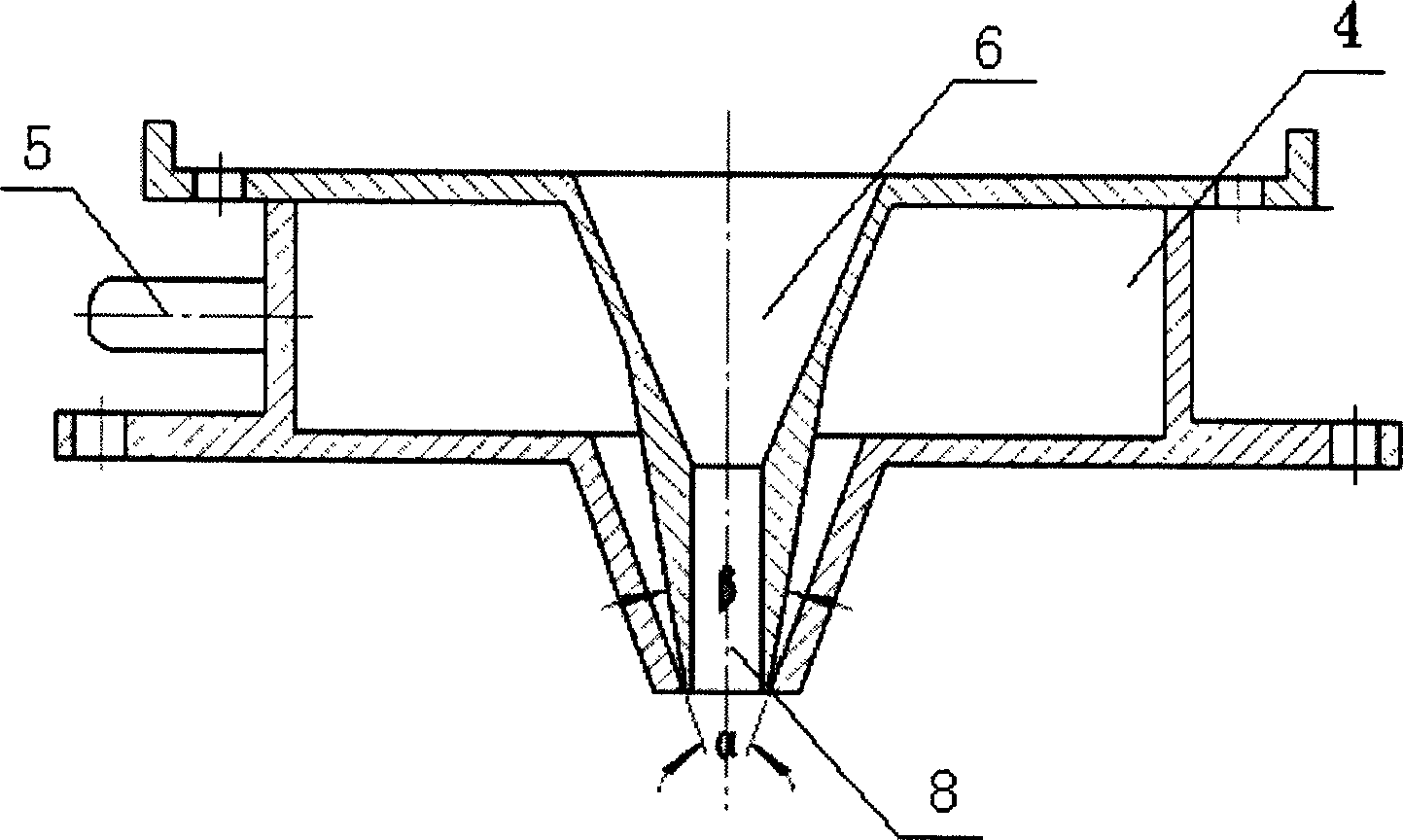

[0019] see figure 1 , the present invention comprises atomization tower 10, and the inlet of atomization tower 10 is connected with melt cavity 6 through the composite atomization nozzle that is made of subsonic atomization nozzle 4 and Laval atomization nozzle 2, and the lower end of atomization tower 10 Connected with the vacuum pump 1, a stopper rod 7 is set in the melt chamber 6, and a liquid guide pipe that runs through the subsonic atomization nozzle 4 and the Laval atomization nozzle 2 is also arranged between the melt chamber 6 and the atomization tower 10 8. Subsonic atomizing nozzle 4 and Laval atomizing nozzle 2 are respectively provided with subsonic atomizing nozzle inlet 5 and Laval atomizing nozzle inlet 3, melt chamber 6 and subsonic atomizing nozzle 4 They are also respectively connected to the negative pole of the electric field dispersion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com