1,3-urylene di (dithioformate) and its preparation method and application as deoil agent

A technology of dithiocarbamate and ureido dithiocarbamate, applied in 1 field, can solve the problem of high cost of dithiocarbamate, and achieve the effects of easy availability of production raw materials, elimination of pollution, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

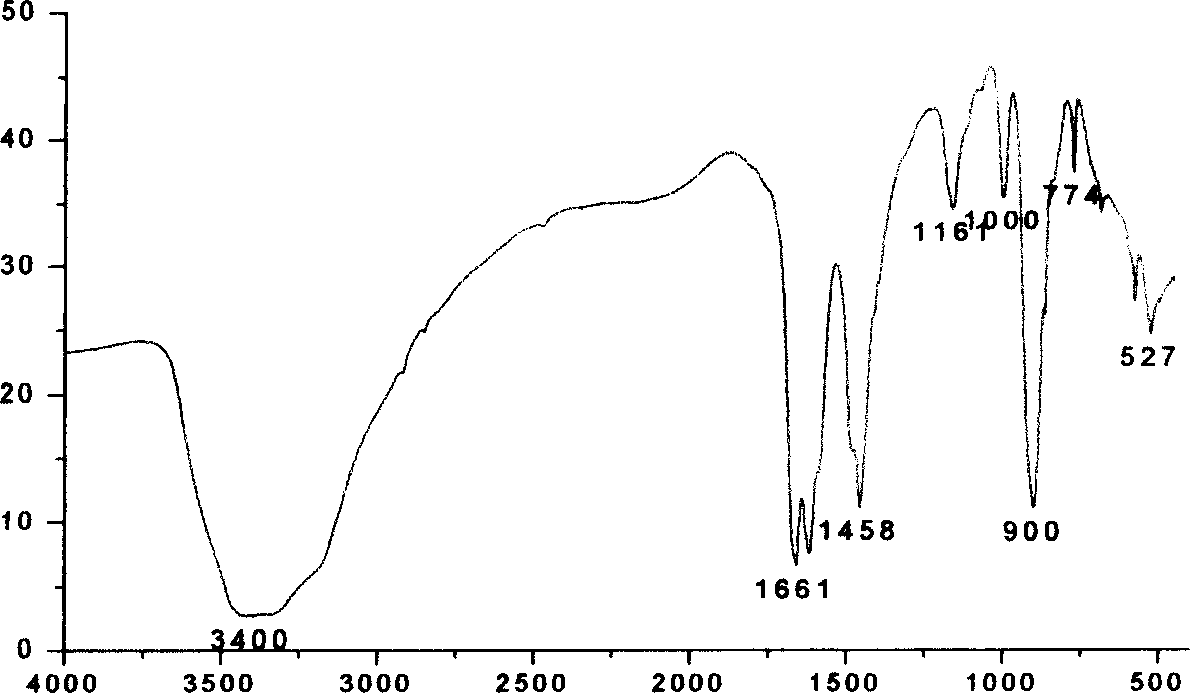

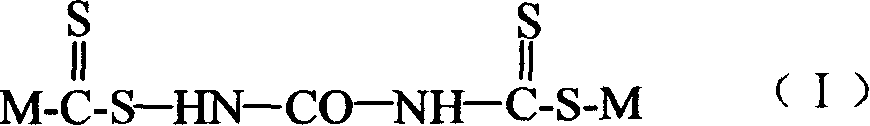

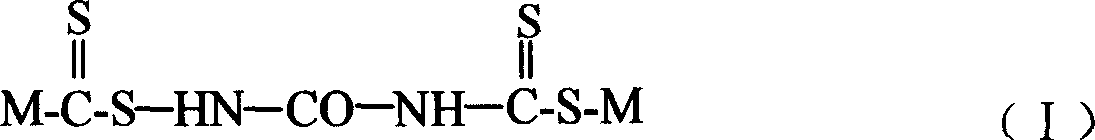

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: the concrete steps of this embodiment are as follows:

[0049] 1. The raw materials and formula (unit-kilogram) of the present embodiment:

[0050] Urea: 100.0 kg

[0051] Carbon disulfide: 238.0 kg

[0052] Sodium hydroxide solution (mass fraction is 50%): 275.0 kilograms

[0053] Sodium gluconate: 1.0 kg

[0054] Water: 386.0 kg

[0055] 2. Process steps and process parameters

[0056] The preparation of the present invention is carried out under normal pressure:

[0057] That is, first add 100.0 kg of urea, 1.0 kg of sodium gluconate and 386.0 kg of water into the reactor. After stirring and dissolving, slowly add 275.0 kg of sodium hydroxide solution at 15°C and dropwise add 238.0 kg of carbon disulfide. After 4.0 hours of reaction, Raise the temperature to 50°C, continue the reaction for 2.0 hours, cool down and discharge the material. The prepared product is a brown-red liquid, or the brown-red liquid is concentrated by vacuum distillation, fil...

Embodiment 2

[0058] Embodiment 2: the concrete steps of this embodiment are as follows:

[0059] 1. The raw materials and formula (unit-kilogram) of the present embodiment:

[0060] Urea: 74.5 kg

[0061] Carbon disulfide: 180.0 kg

[0062] Sodium hydroxide solution (mass fraction is 40%): 248.5 kilograms

[0063] Sodium aluminate: 50 kg

[0064] Water: 447.0 kg

[0065] 2. Process steps and process parameters

[0066] The preparation of the present invention is carried out under normal pressure:

[0067] That is, first add the above-mentioned calculated amount of urea, sodium aluminate and water into the reactor, stir and dissolve, then slowly add sodium hydroxide solution at 20°C while adding carbon disulfide dropwise, after 2.0 hours of reaction, raise the temperature to 70°C, continue After reacting for 1.5h, the temperature was lowered and the material was discharged. The prepared product was a brownish-red liquid.

Embodiment 3

[0068] Embodiment 3: the concrete steps of this embodiment are as follows:

[0069] 1. The raw materials and formula (unit-kilogram) of the present embodiment:

[0070] Urea: 66.7 kg

[0071] Carbon disulfide: 160.0 kg

[0072] Sodium hydroxide solution (mass fraction is 50%): 166.7 kilograms

[0073] Sodium metaaluminate: 65 kg

[0074] Water: 541.6 kg

[0075] 2. Process steps and process parameters

[0076] The preparation of the present invention is carried out under normal pressure:

[0077] That is, first add the above-mentioned calculated amount of urea, sodium metaaluminate and water into the reactor, stir and dissolve, then slowly add sodium hydroxide solution at 25°C and drop carbon disulfide at the same time, after reacting for 5.0 hours, raise the temperature to 55°C, Continue to react for 2.0h, cool down and discharge the material, the prepared product is a brownish red liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com