Surface discharge shadow mask type plasma display panel

A technology of surface discharge and plasma, applied in the direction of solid cathode components, cold cathode tubes, etc., can solve the problems of low yield and high production cost of plasma display panel barriers, and achieve low cost, high luminous efficiency, and simple production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

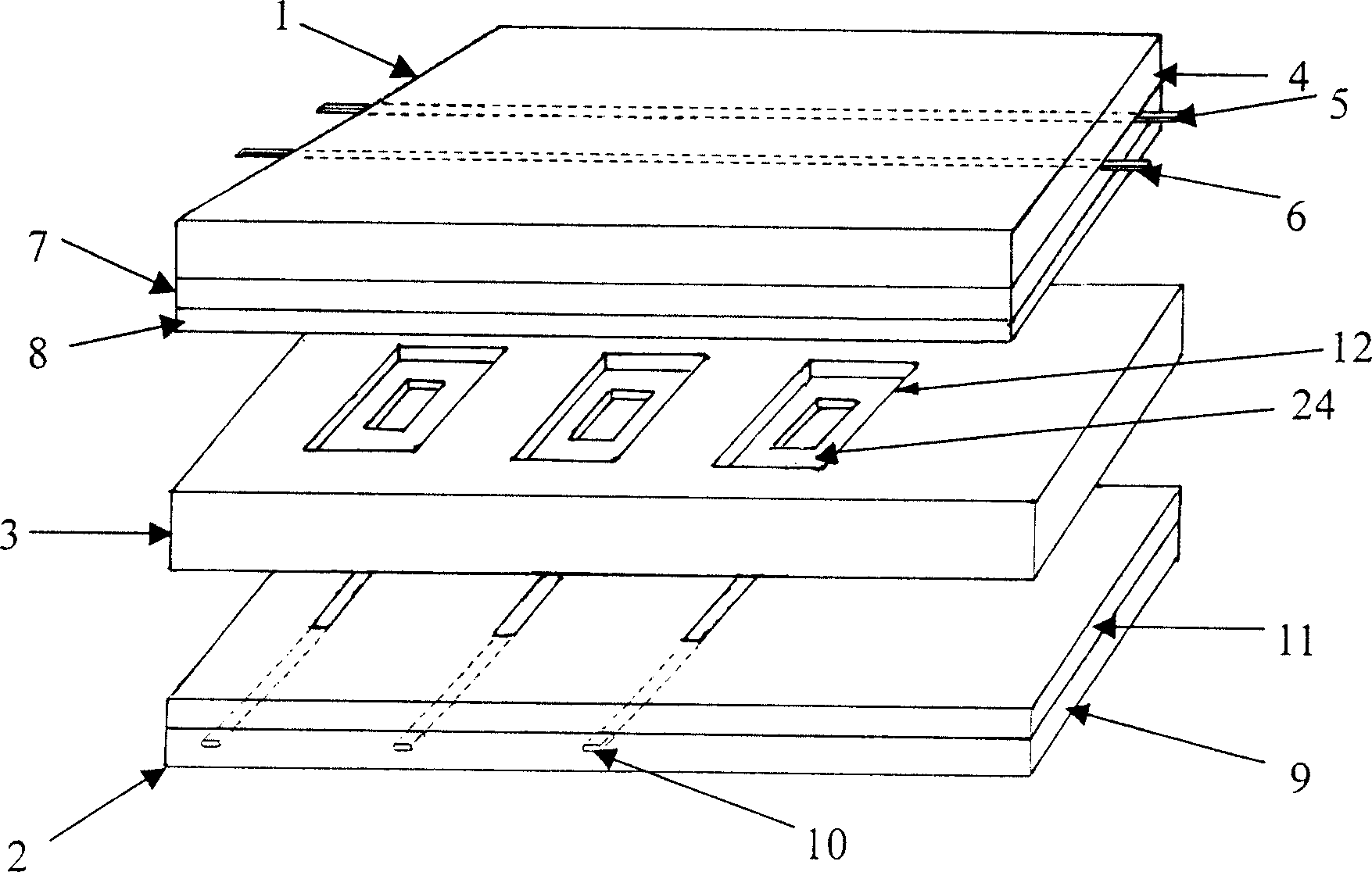

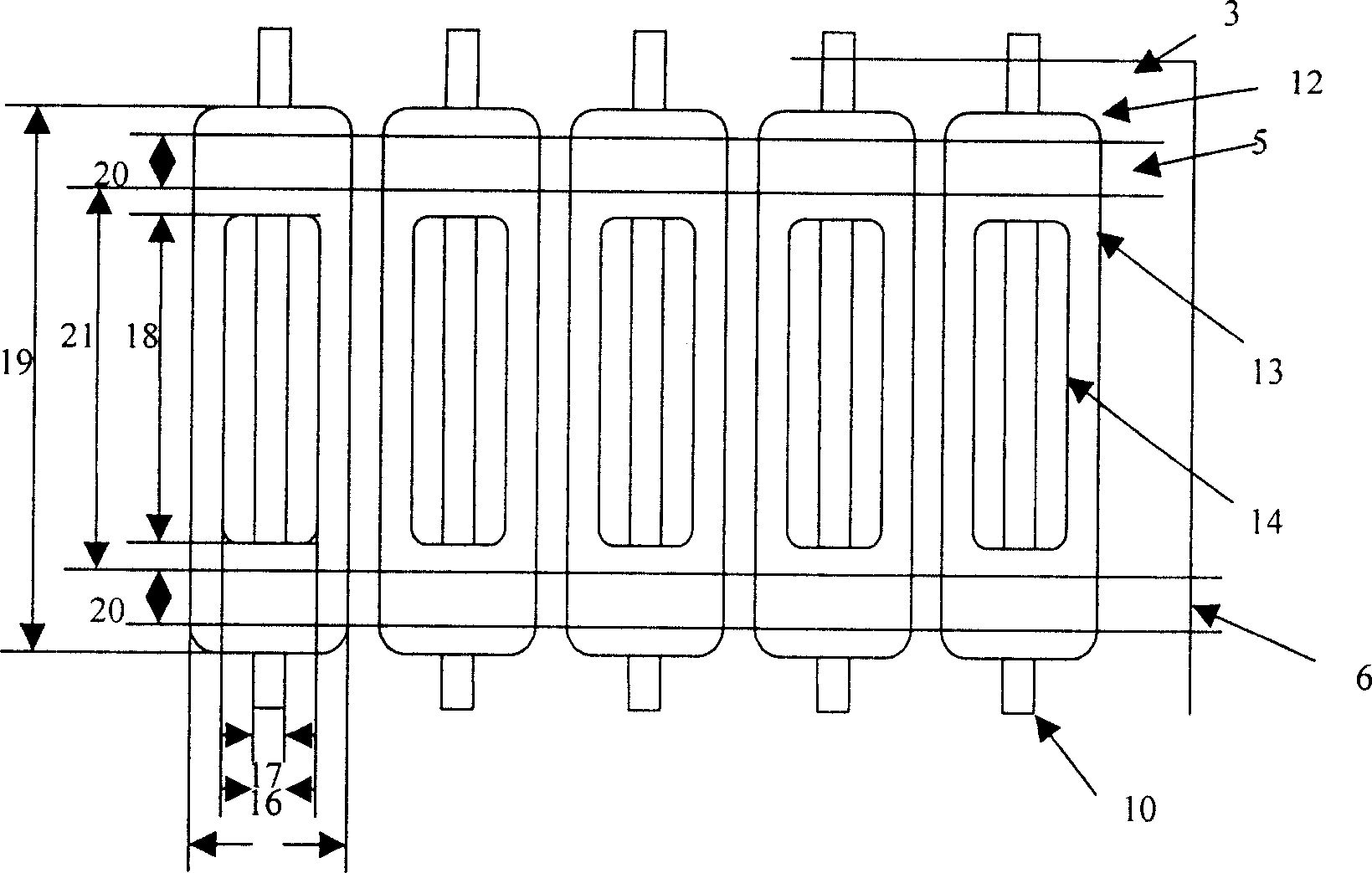

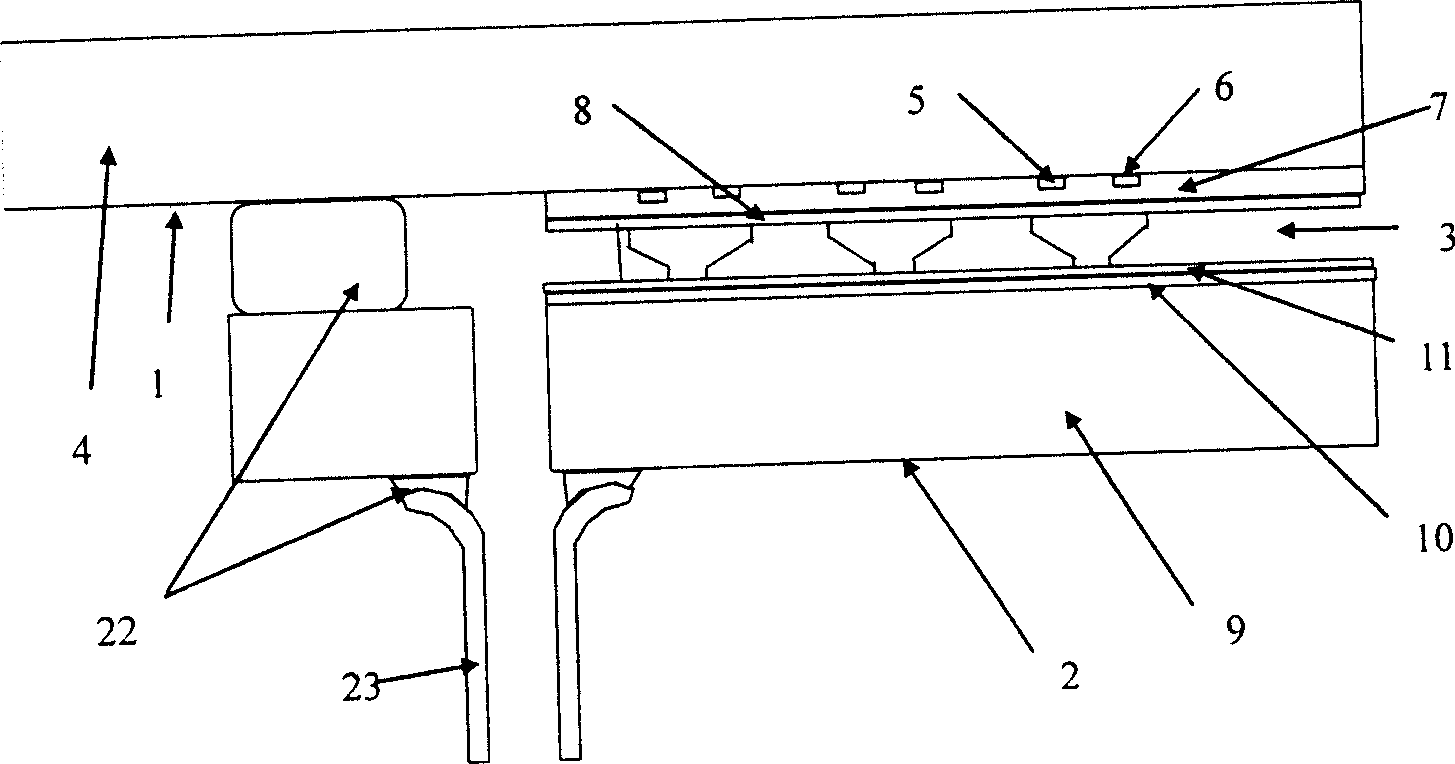

[0024] Such as Figure 1-5 shown

[0025] A surface discharge type shadow mask type plasma display panel, such as figure 1 As shown, it includes a front substrate 1 , a rear substrate 2 , and a shadow mask 3 , wherein the shadow mask 3 is located between the front and rear substrates 1 and 2 . The front substrate 1 is mainly composed of a front substrate glass substrate 4, first electrode pairs 5, 6, a dielectric layer 7, and a protective film 8, wherein the first electrode pairs 5, 6 are arranged in parallel and located on the front substrate glass substrate 4 On the top, it is only composed of Al or Ag electrodes, and there is no electrode composed of transparent conductive film (ITO). The electrode 5 is called a scan electrode, and the electrode 6 is called a sustain electrode. The dielectric layer 7 covers the first electrode pair 5, 6 to protect The membrane 8 covers the dielectric layer 7 . The rear substrate 2 is mainly composed of a rear substrate glass substrate 9,...

Embodiment 2

[0030] In the above-mentioned first embodiment, the shadow mask grid holes 12 form upper openings of any polygonal structure such as elongated, quadrilateral, circular, trapezoidal, hexagonal or octagonal, and the lower openings are elongated, and meet the requirements of the upper and lower openings. The condition that the center of the opening is on a straight line perpendicular to the mask surface. Such as Figure 4 , which constitutes the second embodiment group of the present invention, and the working principle is the same as that of the first embodiment.

Embodiment 3

[0032] In the above-mentioned first and second embodiments, the monochrome phosphor powder 24 is coated on the inner wall of the shadow mask grid hole 12 and the array formed by the surface part of the dielectric layer 11 of the rear substrate 2 corresponding to the lower opening 14, and is filled with a suitable Working gas, so that it produces ultraviolet light of corresponding wavelength to excite the ultraviolet phosphor to emit monochromatic visible light, thereby realizing image display, which constitutes the third embodiment group of the present invention, that is, monochromatic surface type shadow mask plasma display plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com