Food garbage processor

A food waste treatment and heater technology, which is applied in the direction of grain treatment, wrapped objects, packaging/bundling objects, etc., can solve the problems of reduced safety, complicated lid structure, and design lid restrictions, etc., so as to improve merchandise and facilitate use , to avoid the effect of excessive temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, illustrate in detail the specific content of the present invention:

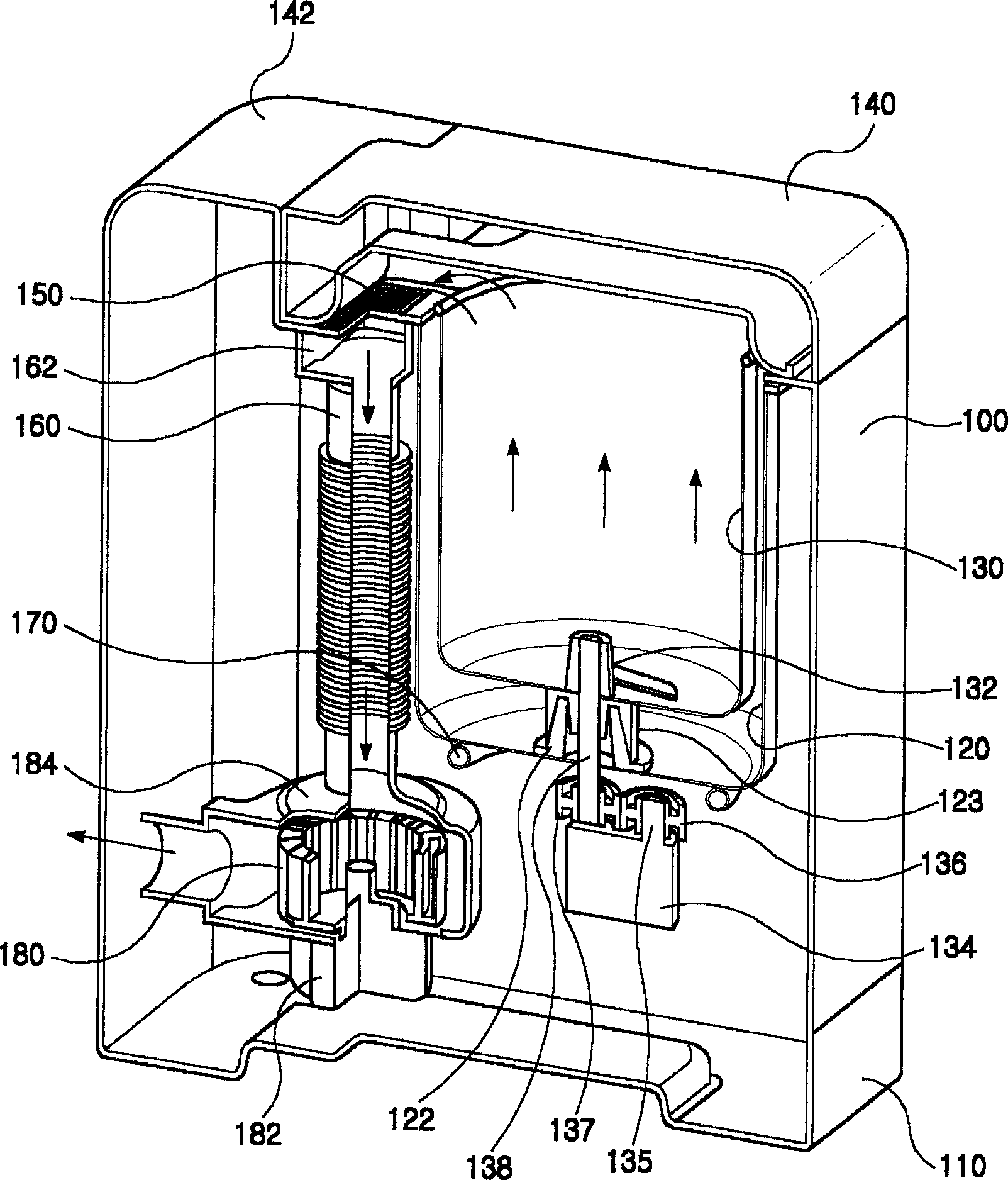

[0023] attached figure 1 It is a perspective view of the internal structure of the food waste disposer used in the present invention.

[0024] From figure 1 It can be seen from the figure that the food waste disposer in the present invention is mainly composed of a main body 100, an outer barrel 120 installed in the main body 100, and a crushing blade installed in the outer barrel 120 with food waste disposal. The inner tub 130 of 132, the motor 134 installed in the main body 100 and driving the crushing blade 132, the heater 170 attached to the outer tub 120 for heating the food waste in the inner tub 130, and the inner tub The exhaust pipe 160 connected with 130, the exhaust fan 180 connected with the exhaust pipe 160 and used to discharge the peculiar smell and water vapor inside the inner tub 130, used to control the motor 134 and the heater 170 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com