Self-dense concrete of mixed fiber with fly ash in use for prefabricated acoustic barrier

A technology of self-compacting concrete and hybrid fiber, which is applied in the field of configuration of fiber concrete and fly ash concrete, self-compacting concrete, hybrid fiber fly ash self-compacting concrete, achieving significant technical advantages, simple production process and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

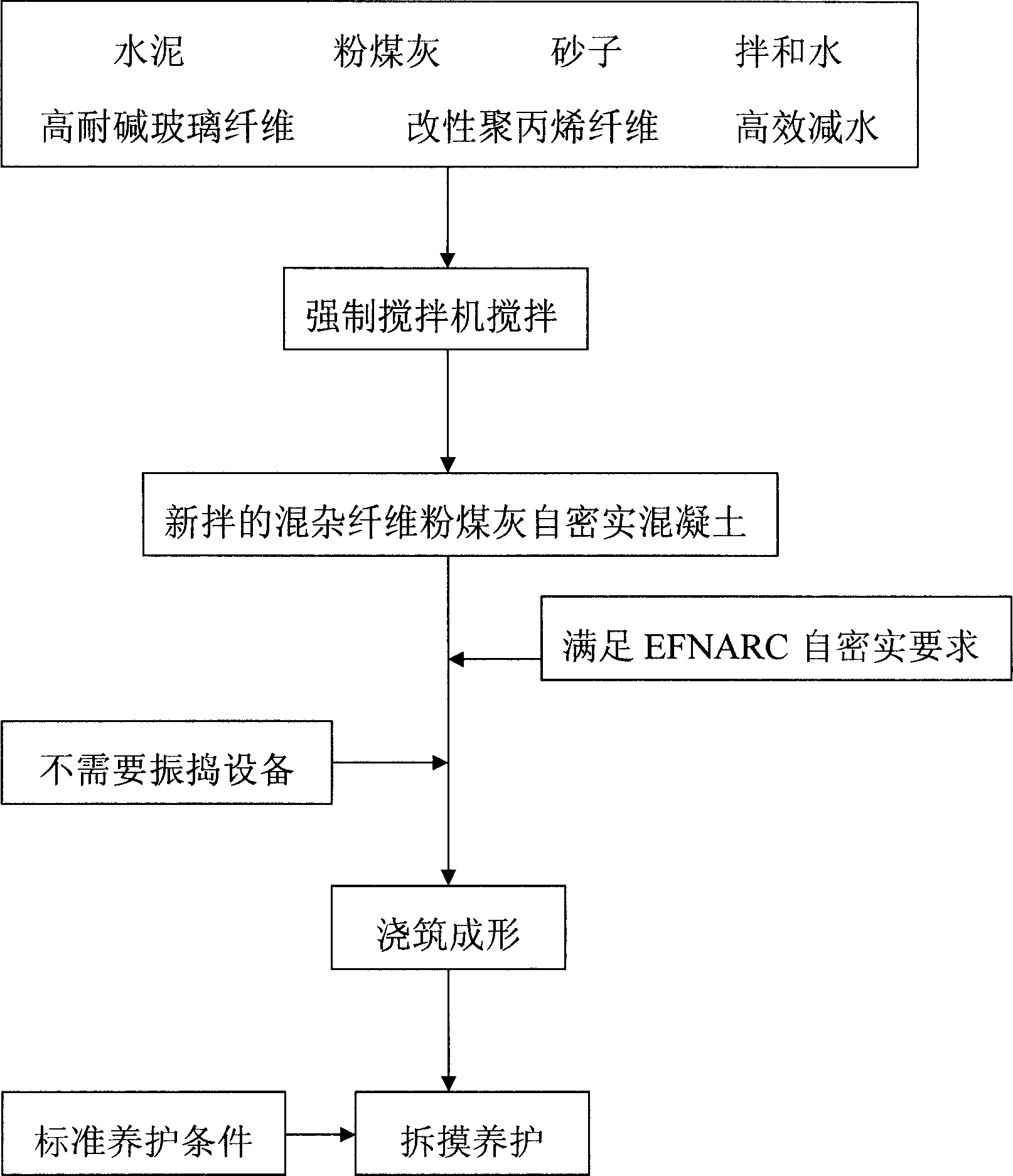

Method used

Image

Examples

Embodiment

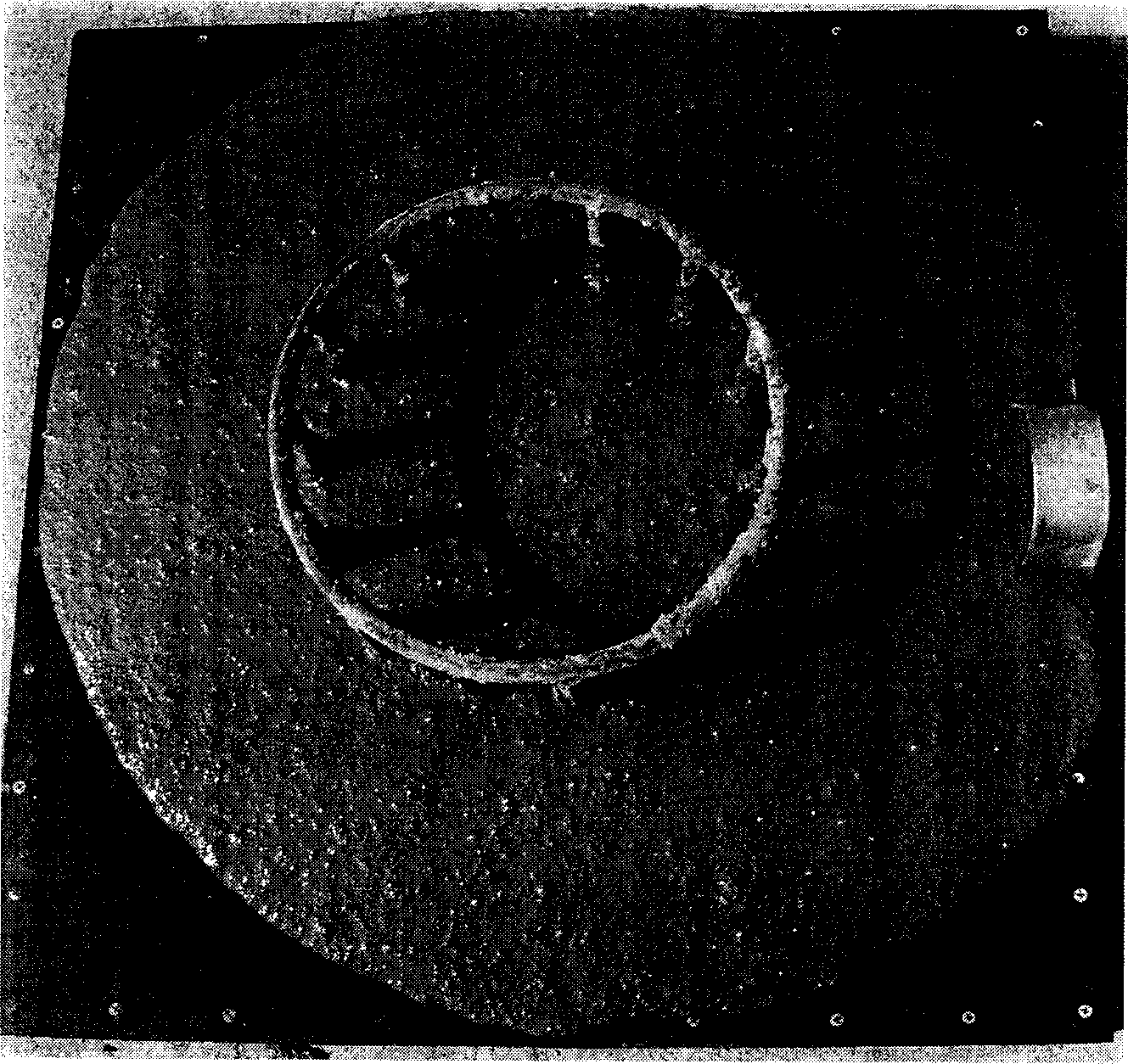

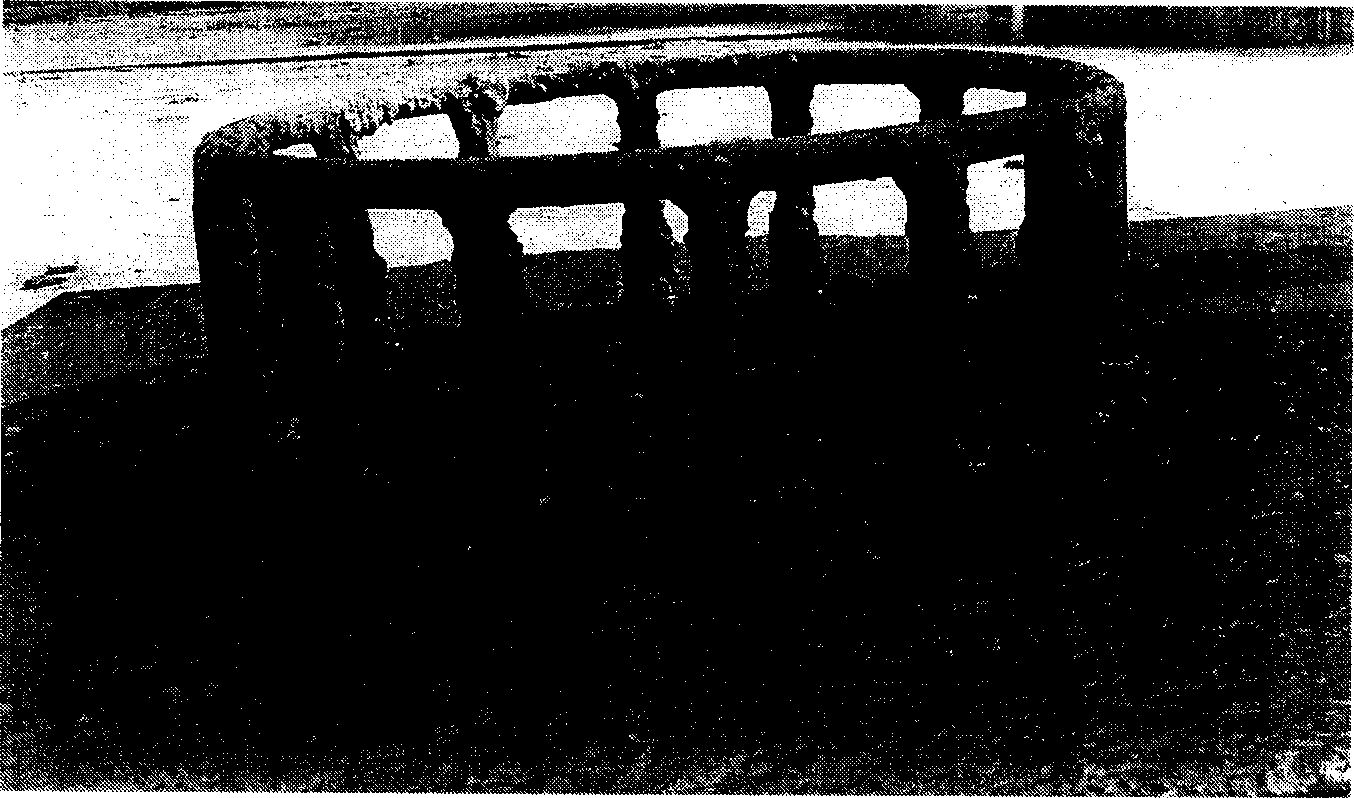

[0028] A hollow sound-absorbing barrier with grids is poured using the self-compacting concrete of the hybrid fiber fly ash of the present invention. In order to compare and study different properties, ordinary fly ash self-compacting concrete without fiber, fly ash self-compacting concrete with glass fiber alone and fly ash self-compacting concrete with polypropylene fiber alone are also configured. Table 1 is the mix ratio of four kinds of concrete, the data unit in the table is kg / m 3 . Table 2 is the parameter description of each component material of the concrete of the embodiment.

[0029] concrete type

[0030] Material

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com