Methanol gasoline additive

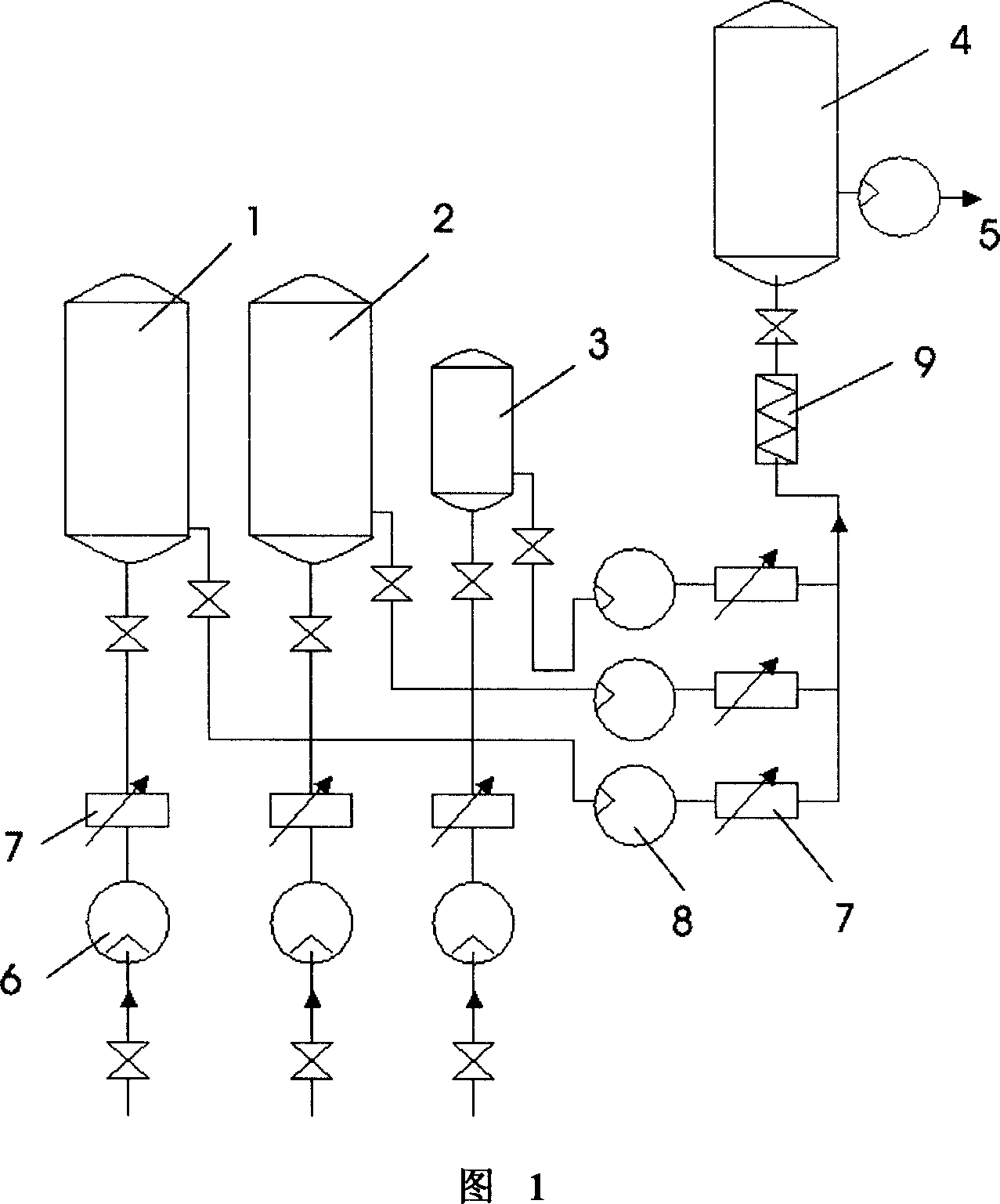

A technology for methanol gasoline and additives, applied in the field of oil additives, can solve the problems of restricting the application and development of methanol gasoline, and achieve the effects of small footprint, labor saving and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

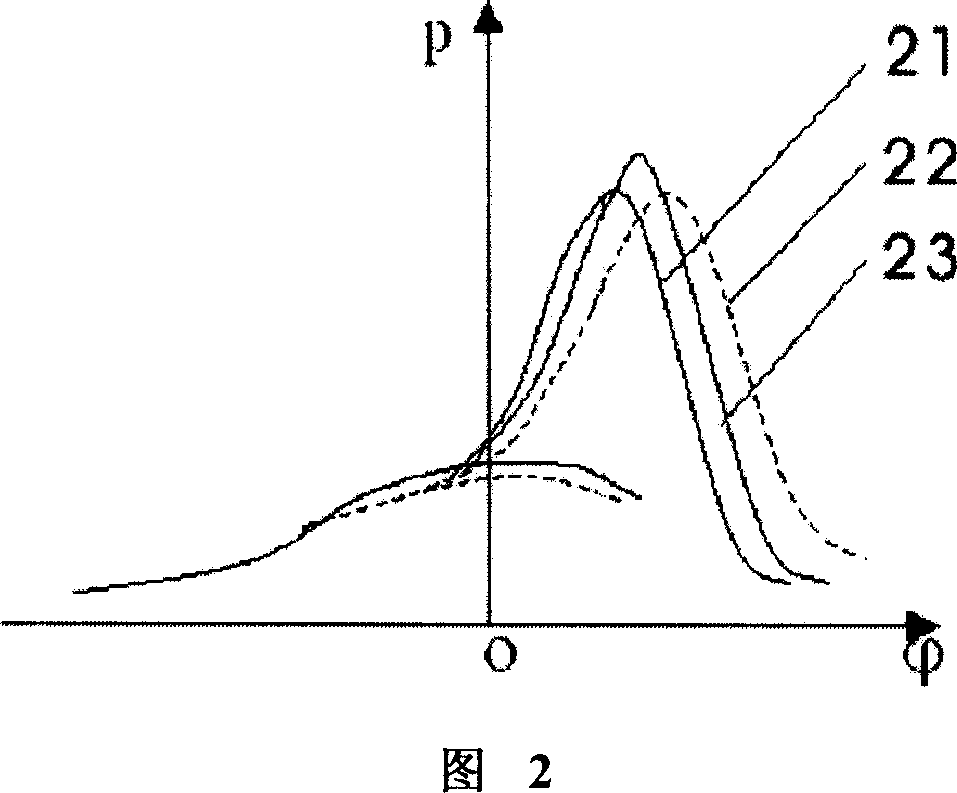

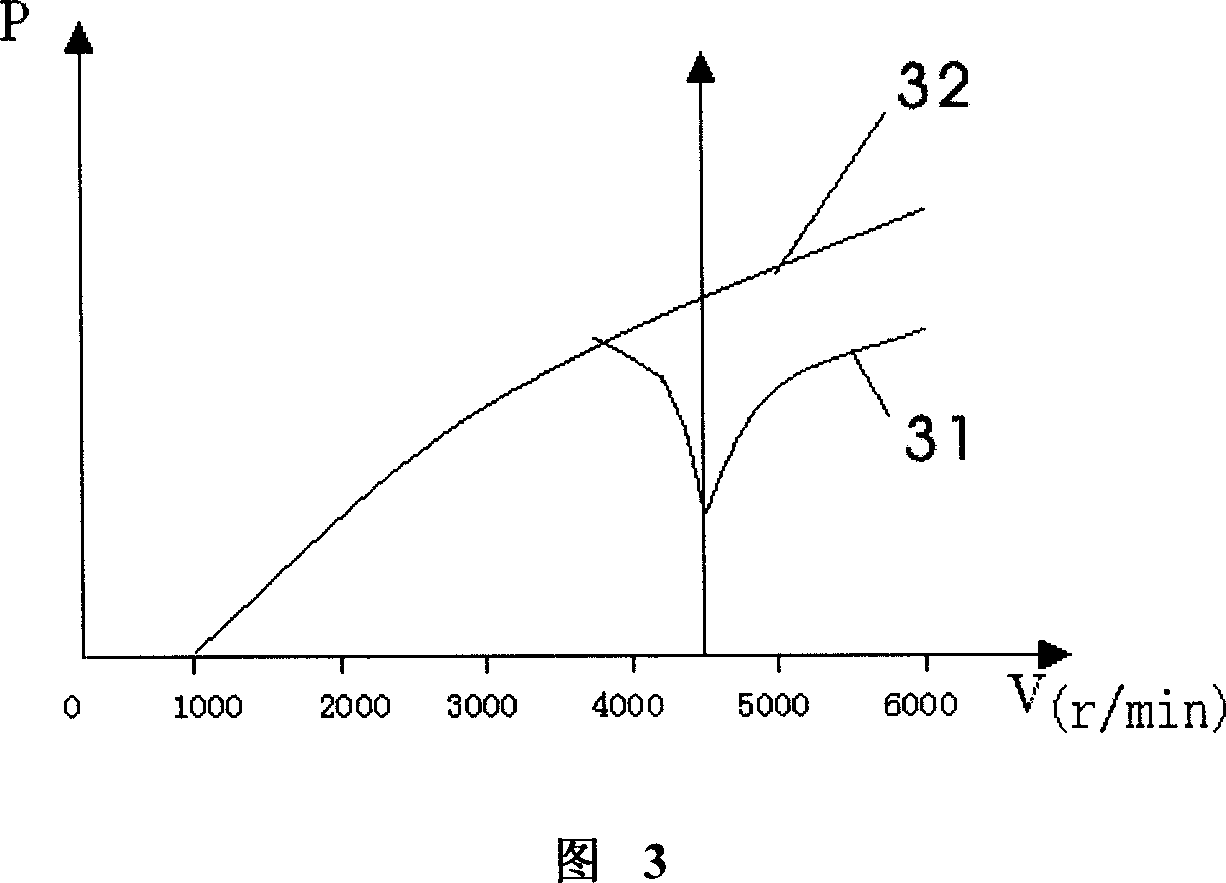

Method used

Image

Examples

Embodiment 1

[0055] A methanol gasoline additive, under normal temperature and pressure, is mixed with the following raw material formula by conventional public mixing methods.

[0056] The raw material of this methanol gasoline additive and its weight ratio are:

[0057] 2.5 parts of ethane, 2 parts of n-hexane, 36 parts of methyl tert-butyl ether, 6 parts of ethanol, 0.5 parts of 2,2-dimethylbutane, 1 part of tert-butanol, 2 parts of n-propanol, 2-ethyl alcohol 2.4 parts of (-1-) ethanol, 5 parts of glycol, 2 parts of 1,3-dihydroxybutane, 8 parts of neopentyl glycol, 2 parts of 1,6-dihydroxyhexane, 4 parts of trimethylolpropane 5 parts of pentaerythritol, 5 parts of diisopropyl ether, 3 parts of ethyl 2-ethylenedioxyacetate, 2.5 parts of isopropyl nitrate, 8 parts of dimethyl ketone, 2 parts of ethyl malonate, diphenyl carbonate 0.5 part of ester, 0.3 part of 102TB corrosion inhibitor, 0.3 part of 107PT anti-swelling agent.

Embodiment 2

[0059] A methanol gasoline additive, under normal temperature and pressure, is mixed with the following raw material formula by conventional public mixing methods.

[0060] The raw material of this methanol gasoline additive and its weight ratio are:

[0061] 3 parts of ethane, 1 part of n-hexane, 50 parts of methyl tert-butyl ether, 4 parts of ethanol, 1 part of 2,2-dimethylbutane, 5 parts of tert-butanol, 1 part of n-propanol, 2-ethyl alcohol 0.5 parts of (-1-) ethanol, 2 parts of glycol, 1 part of 1,3-dihydroxybutane, 3.5 parts of neopentyl glycol, 0 parts of 1,6-dihydroxyhexane, 3 parts of trimethylolpropane 8 parts of pentaerythritol, 6.7 parts of diisopropyl ether, 1 part of ethyl 2-ethylenedioxyacetate, 1 part of isopropyl nitrate, 5 parts of dimethyl ketone, 1 part of ethyl malonate, diphenyl carbonate 2 parts of ester, 0.2 part of 102TB corrosion inhibitor, 0.1 part of 107PT anti-swelling agent.

Embodiment 3

[0063] A methanol gasoline additive, under normal temperature and pressure, is mixed with the following raw material formula by conventional public mixing methods.

[0064] The raw material of this methanol gasoline additive and its weight ratio are:

[0065] 2 parts of ethane, 2 parts of n-hexane, 40 parts of methyl tert-butyl ether, 8 parts of ethanol, 3 parts of 2,2-dimethylbutane, 5 parts of tert-butanol, 4 parts of n-propanol, 2-ethyl alcohol 2 parts of (-1-) ethanol, 3 parts of glycol, 0 parts of 1,3-dihydroxybutane, 2 parts of neopentyl glycol, 1 part of 1,6-dihydroxyhexane, 2 parts of trimethylolpropane 2 parts of pentaerythritol, 12 parts of diisopropyl ether, 2 parts of ethyl 2-ethylenedioxyacetate, 3 parts of isopropyl nitrate, 2 parts of dimethyl ketone, 2 parts of ethyl malonate, diphenyl carbonate 2.3 parts of ester, 0.5 part of 102TB corrosion inhibitor, 0.2 part of 107PT anti-swelling agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com