Infrared transparent fluozirconate microcrystalline glass and preparation method thereof

A fluorozirconate, glass-ceramic technology, used in glass manufacturing equipment, glass furnace equipment, manufacturing tools, etc., can solve the problem of not making great progress, low chemical stability and mechanical properties of fluoride glass, hindering optical applications and other problems, to achieve the effect of good transmittance, good mechanical properties and good anti-devitrification properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and 2

[0026] Embodiments 1 and 2 are only different in glass formula composition, but the glass melting process is the same. The specific process from glass melting to heat treatment microcrystallization is as follows:

[0027] (1) Melting of fluorozirconate glass: Weigh the raw materials according to the glass formula in Table 1, mix the powdered raw materials evenly, put them in a platinum crucible and melt them in a silicon carbide rod electric furnace at 1000-1050 °C, completely After being melted and clarified for 15-20 minutes, the molten glass is poured on a preheated graphite mold, and then the glass is quickly moved into a muffle furnace heated to 310°C for annealing. The annealing process is: keep warm at 310°C for 3 to 4 hours, then drop to 200°C at a rate of 3°C / hour, and finally drop to room temperature at a rate of 5°C / hour, and take out the glass sample after complete cooling.

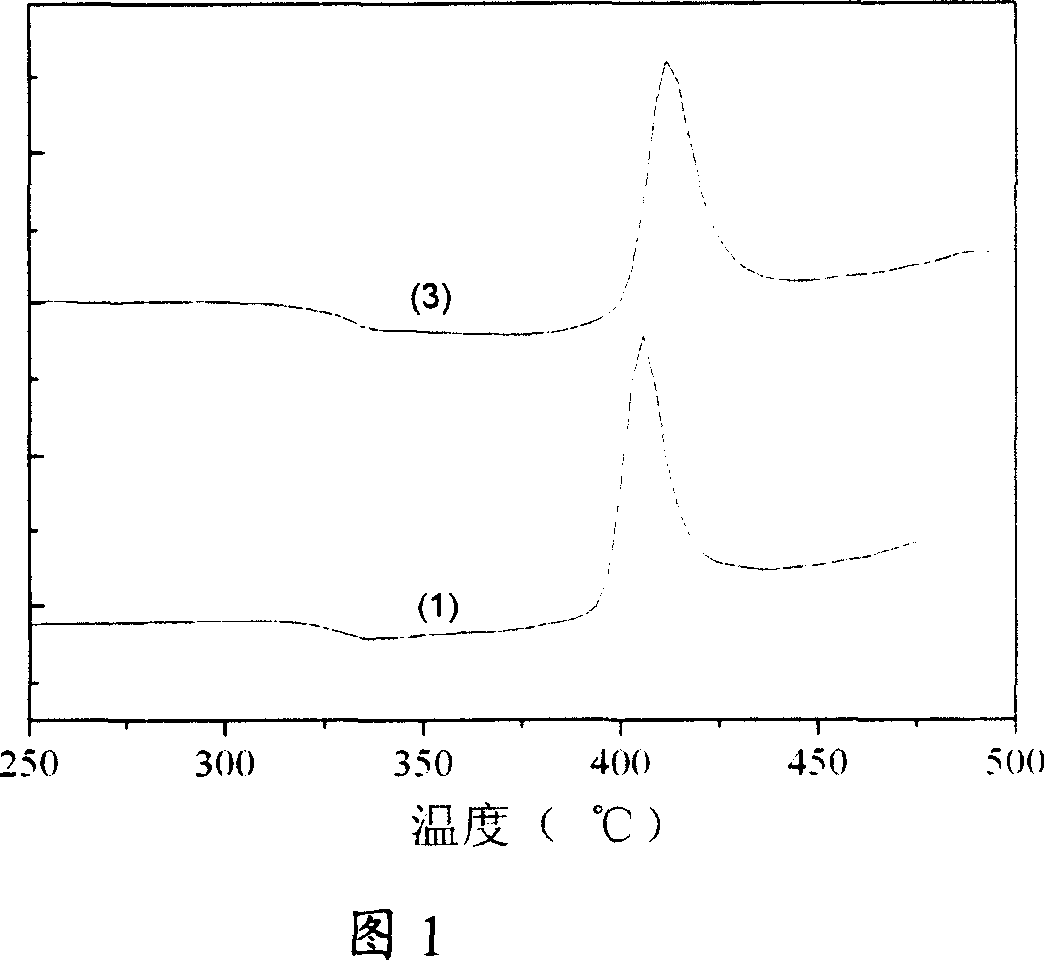

[0028] (2) Preparation method of fluorozirconate glass-ceramics: According to glass therm...

Embodiment

[0029] Examples: 3, 4 and 5:

[0030] Concrete preparation process is as follows:

[0031] The first step: carry out batching according to the glass component of embodiment 3,4 and 5 described in table 1; The process is essentially the same, with a slight increase in the temperature at which the glass is melted and the temperature at which the glass is annealed.

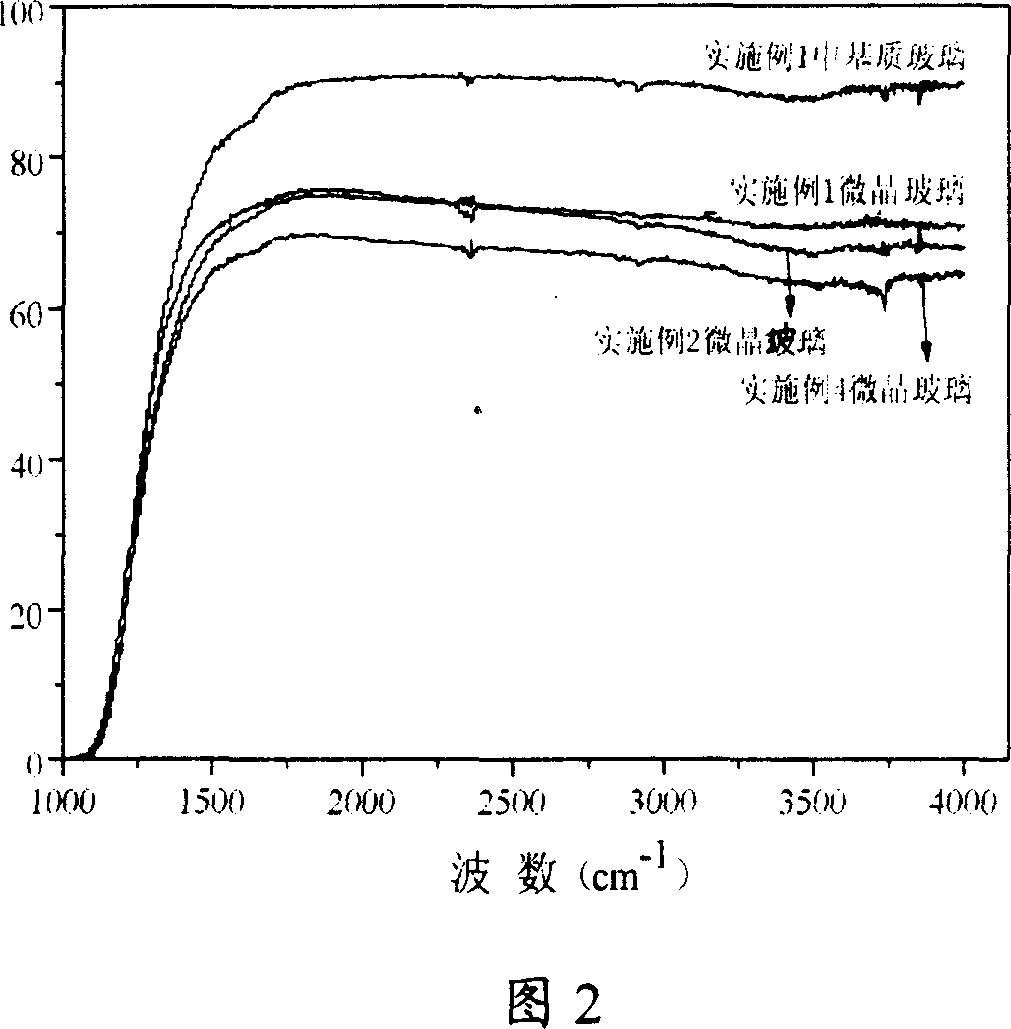

[0032] Second step: the preparation process of embodiment 3, 4 and 5 fluoride glass-ceramics is basically the same as that of embodiment 1 and 2, that is, according to the glass thermal analysis (DTA) data, the glass sample made is changed from room temperature to 10 °C / min rate of heating above T g After nucleation at a temperature above 20°C for 4 to 5 hours, heat to the first crystallization peak temperature at a rate of 0.5°C / min (T x ) in the vicinity of crystallization for 30 to 50 minutes, and finally cooled to room temperature at a rate of 1° C. / min and then taken out to obtain transparent fluorozirconate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com