High refraction and low dispersion optical glass and manufacturing method thereof

An optical glass and manufacturing method technology, applied in glass manufacturing equipment, glass pressing, manufacturing tools, etc., can solve the problems of high price, reduced transmittance, high cost, etc., and achieve low-cost operation and mass production, good resistance Devitrification, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] Embodiment 1 The properties of the optical glass of the present invention

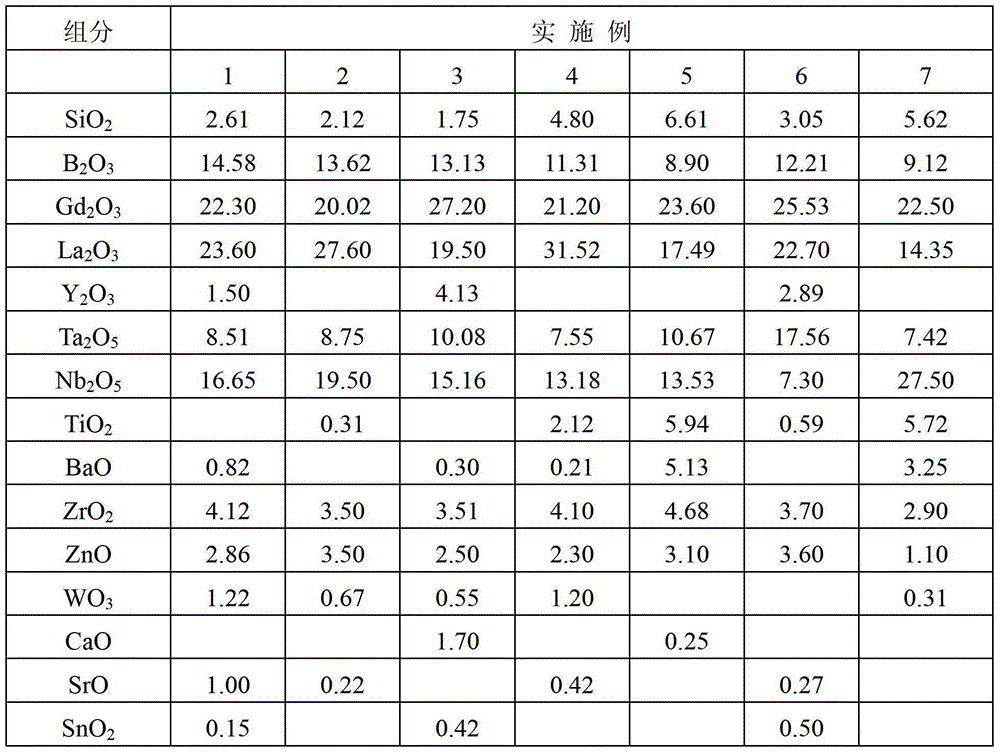

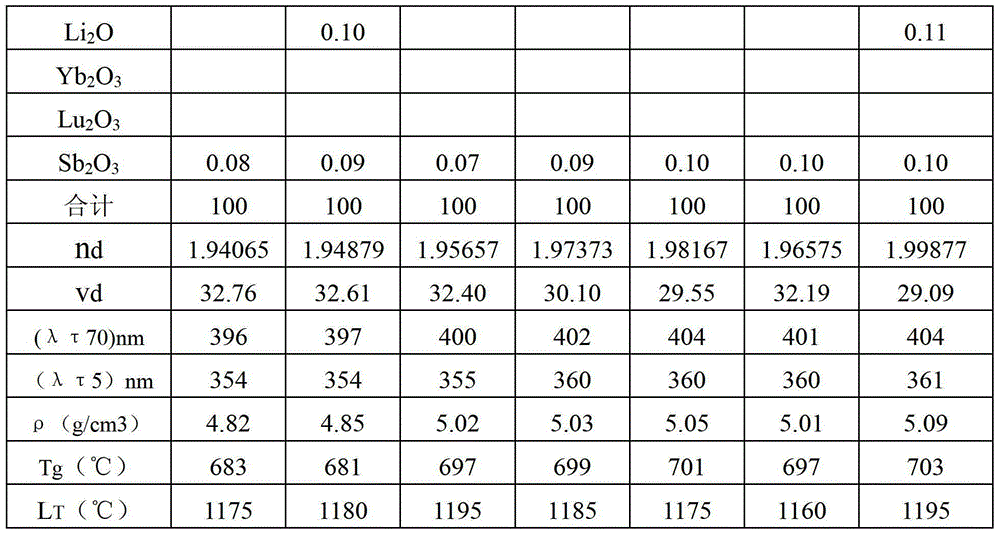

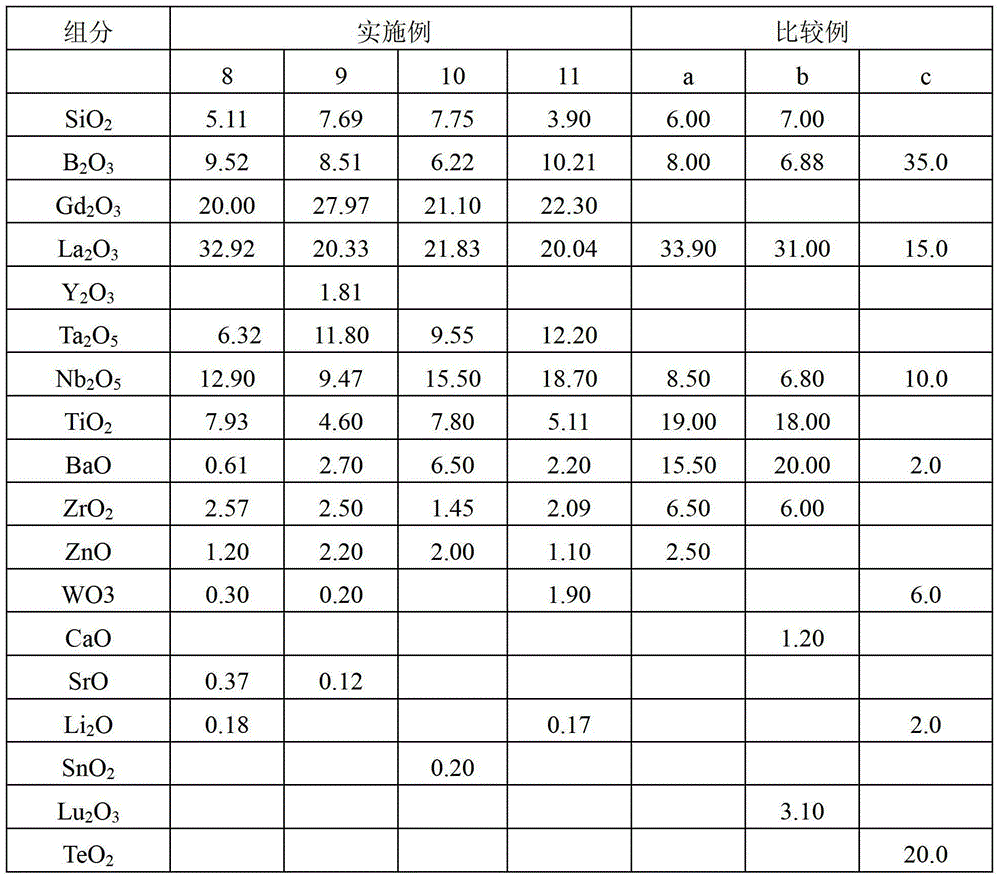

[0095] Tables 1 and 2 show the glass composition of Examples No. 1 to No. 11 of the optical glass of the present invention and the composition of Comparative Examples No. 1 to No. c of the same type of high refraction glass as the glass of the present invention. The optical glass obtained by annealing at -4.0 / h and cooling in each example and comparative example is measured as follows, the refractive index (nd), Abbe number (vd), internal transmission (λτ70) and (λτ5), The measurement results of density (ρ), transition temperature (Tg) and liquidus temperature (LT) are given in Tables 1 and 2.

[0096] The corresponding raw materials such as various oxides, carbonates and nitrates of the raw materials of each component are weighed and mixed according to the composition of each embodiment and comparative example to make a batch, which is added to a platinum container or After melting, stirring, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

| liquidus temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com