Electrophotography photoreceptor

一种电子照相、感光体的技术,应用在光学、电记录术、仪器等方向,能够解决缺乏耐久性、感光度低等问题,达到抑制影像模糊、分散性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example 1

[0174] Specific examples of the hole transport agent include compounds represented by the following general formulas (17) to (20).

[0175]

[0176] In general formula (17), R 1a ~R 12a Each independently, is a hydrogen atom, a halogen atom, a substituted or unsubstituted alkyl group with 1 to 12 carbon atoms, a substituted or unsubstituted alkoxy group with 1 to 12 carbon atoms, or a substituted or unsubstituted carbon atom An aryl group with 6 to 30 carbon atoms, a substituted or unsubstituted alkenyl group with 6 to 30 carbon atoms, and -OR 13a (R 13a A group represented by an alkyl group with 1 to 10 carbon atoms, a perfluoroalkyl group, or an aryl group with 6 to 30 carbon atoms), R 1a ~R 5a , R 6a ~R 10a , R 11a and R 12a Two substituents can be connected to each other to form a saturated or unsaturated ring, Ar 1a is a hydrogen atom, a substituted or unsubstituted alkyl group having 1 to 12 carbon atoms, a substituted or unsubstituted aryl group having 6 to ...

specific example 2

[0195] In addition, specific examples of the hole transport agent include compounds (HTM-1 to 4) represented by the following formulas (21) to (24).

[0196]

[0197]

[0198] (2)-4 addition amount

[0199] It is characterized in that the addition amount of the hole transport agent is set to a value within the range of 1 to 100 parts by weight with respect to 100 parts by weight of the binder resin.

[0200] The reason is that if the amount of the hole transport agent added is less than 1 part by weight, the sensitivity characteristics of the photoreceptor layer may not be maintained after predetermined continuous printing.

[0201] On the other hand, if the amount of the hole transport agent added exceeds 100 parts by weight, it may be difficult to mix and disperse uniformly or crystallize easily.

[0202] Therefore, with respect to 100 parts by weight of the binder resin, the amount of the hole transport agent to be added is more preferably within a range of 5 to 80 p...

Embodiment 1

[0301] 1. Fabrication of Electrophotographic Photoreceptor

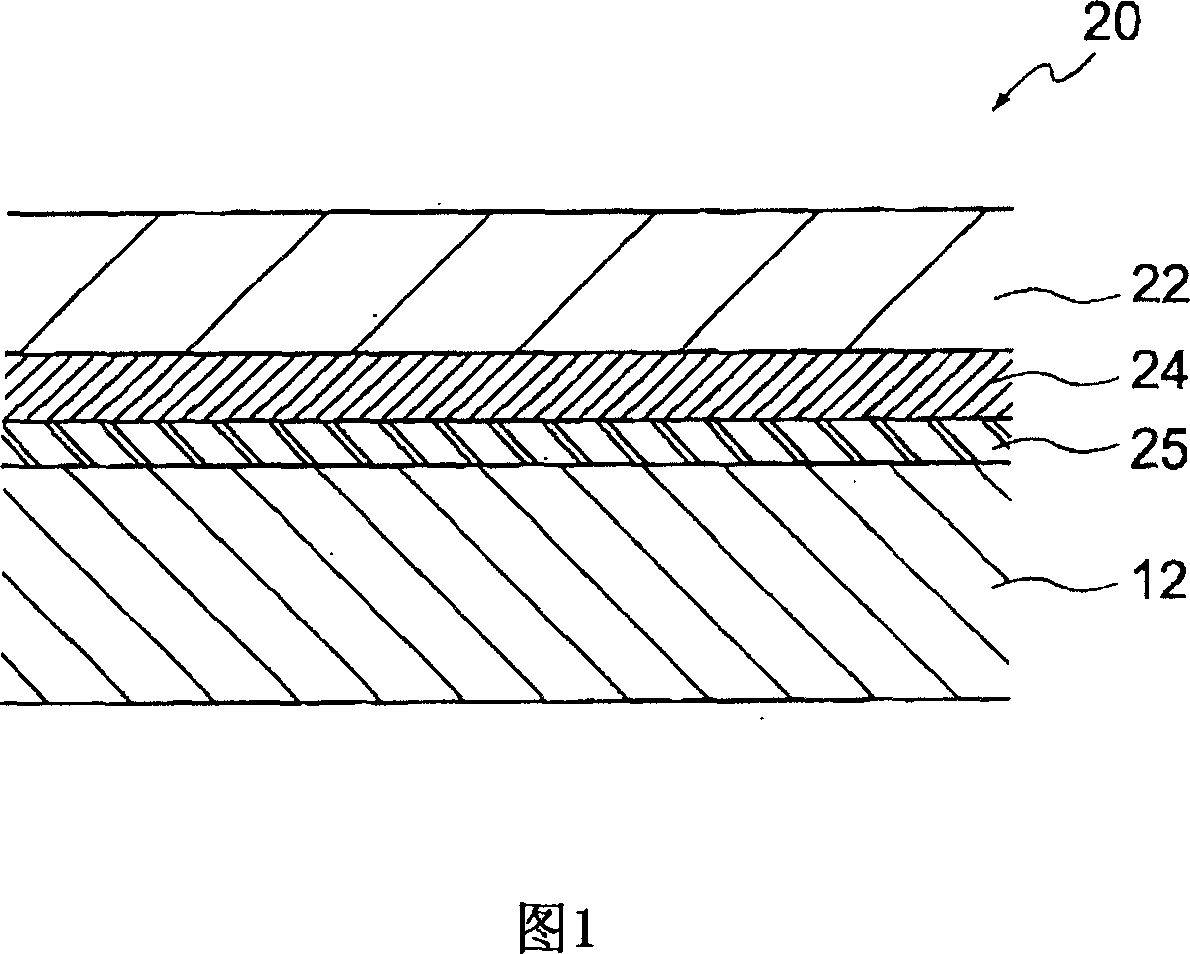

[0302] On the conductive support, an intermediate layer, a charge generating layer, and a charge transporting layer were sequentially formed to prepare the laminated electrophotographic photoreceptor of Example 1.

[0303] (1) Formation of the middle layer

[0304] The intermediate layer was formed as follows. Using a paint shaker, 2.5 parts by weight of titanium oxide (surface-treated with MT-02, alumina, silica, and silicone, with a number-average primary particle diameter of 10 nm (manufactured by TAYCA)) was added, and a quaternary copolymerization 1 part by weight of polyamide resin CM8000 (manufactured by TORAY Corporation), 10 parts by weight of methanol as a solvent, and 2.5 parts by weight of n-butanol were dispersed for 10 hours, and then filtered through a 5-micron filter to prepare a coating for the intermediate layer. cloth liquid.

[0305] Next, one end of an aluminum substrate (supporting substrate)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com