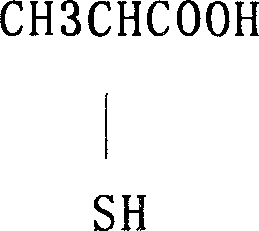

Prepn process of 2-mercapto propanoic acid

A technology of mercaptopropionic acid and sodium mercaptopropionate, which is applied in the preparation of mercaptans, organic chemistry, etc., can solve the problems of high cost, low yield, difficult marketization of products, etc., and achieves increased yield, reduced production cost, Inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

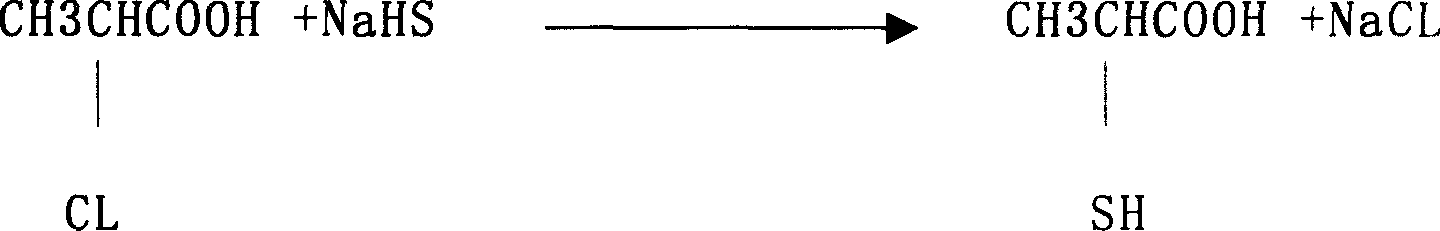

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with embodiment, but does not limit the present invention. Specifically include the following steps:

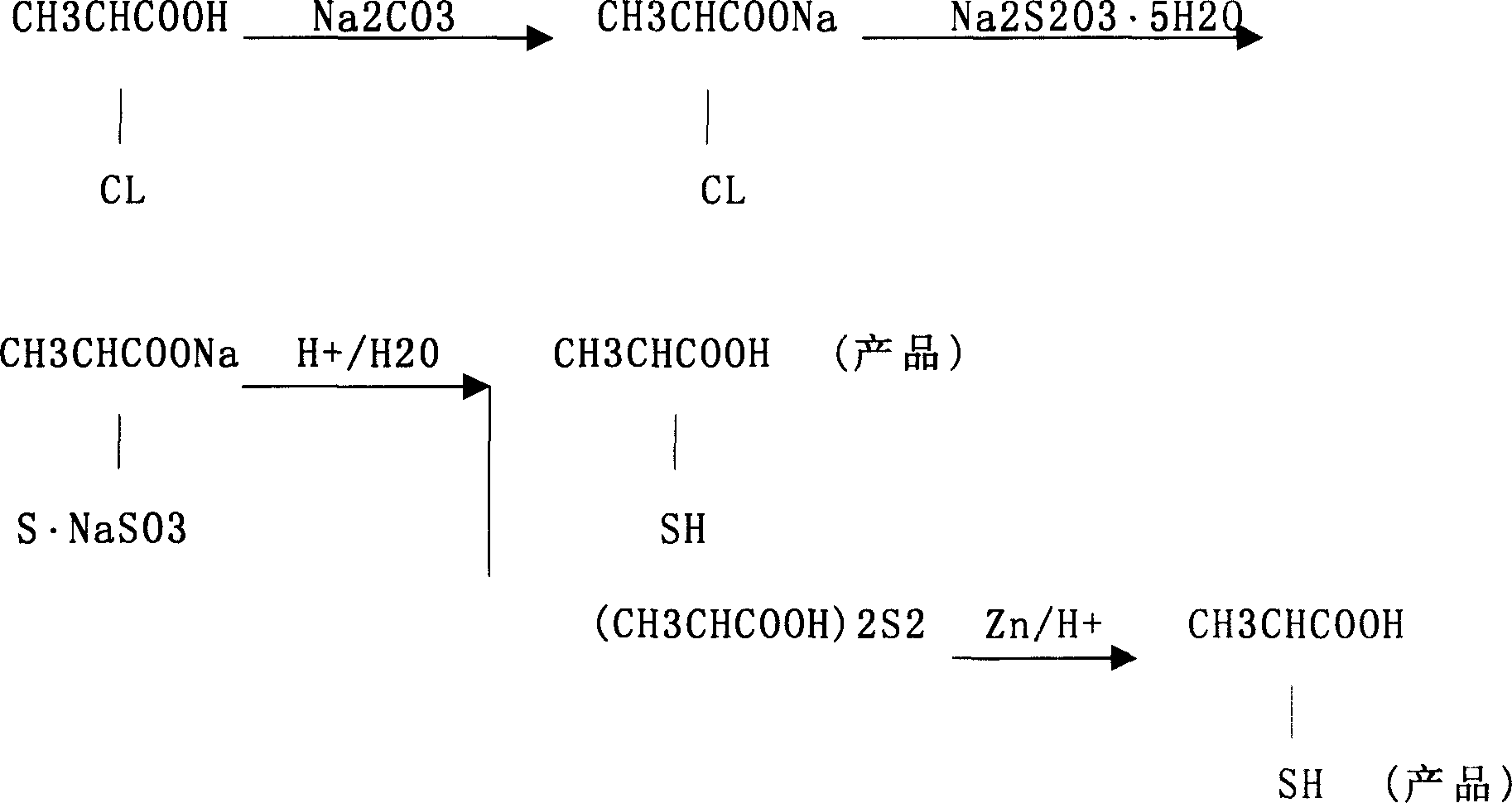

[0026] (1), the preparation of mixed solution:

[0027] First, add 116 grams of sodium carbonate to 400 grams of water to dissolve, slowly add 224 grams of 2-chloropropionic acid to react to obtain a 2-chloropropionic acid sodium reaction solution, and the pH value of the reaction solution is 7.0-7.5;

[0028] Then, 600 grams of sodium thiosulfate are added and dissolved in 400 grams of water to make an aqueous solution of sodium thiosulfate;

[0029] Then, add the sodium thiosulfate aqueous solution to the 2-chloropropionate sodium reaction liquid at 70-75°C after 1 hour to react to generate 2-thiopropionate sodium and 2-mercaptopropionic acid, 2-mercaptopropionic acid Sodium, sodium dithiodipropionate, dithiodipropionic acid mixture.

[0030] Finally, the reaction mixture was kept at 70° C. for 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com