Pre-treating process for preparing biological diesel oil with waste animal and vegetable oil

A technology of waste animals and plants and biodiesel, which is applied in the field of pretreatment production process of waste animals and plants to prepare biodiesel, can solve the problems of low concentration of glycerin water, large equipment investment, large energy consumption, etc. The effect of saving and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 3

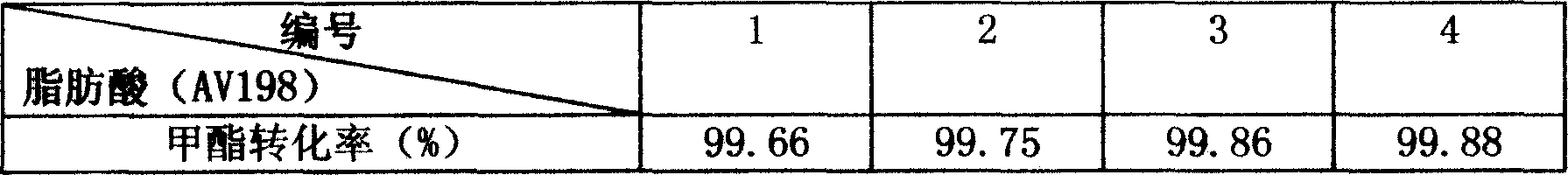

[0019] Example 3: After the fatty acid with AV of 198 obtained by the pretreatment process of the present invention enters the esterification process, the reaction is catalyzed by biological enzymes, and the conversion rate of methyl ester is as high as 99%.

[0020]

example 4

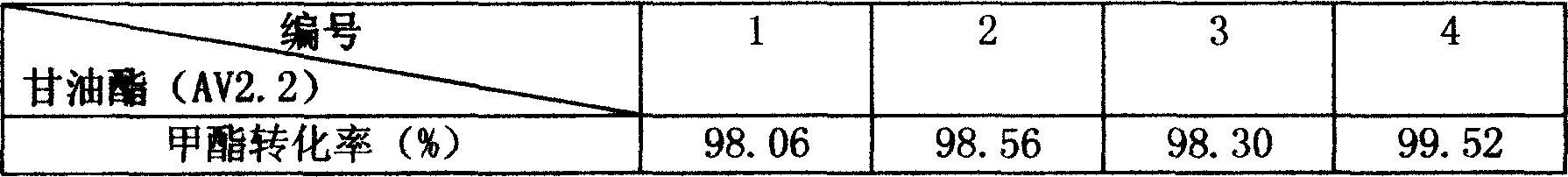

[0021] Example 4: After the glyceride with AV of 2.20 obtained by the pretreatment process of the present invention enters the esterification process, a basic catalyst is used to carry out transesterification reaction, and the conversion rate of methyl ester is as high as 98%.

[0022]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com