Decomposing process for organic garbage and organic garbage thermal decomposing device

A decomposition treatment and organic treatment technology, applied in the field of organic waste decomposition and organic waste thermal decomposers, can solve the problems of power consumption, difficult to popularize and apply, incompatibility, etc., and achieve easy processing and assembly production, easy popularization and application, Small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

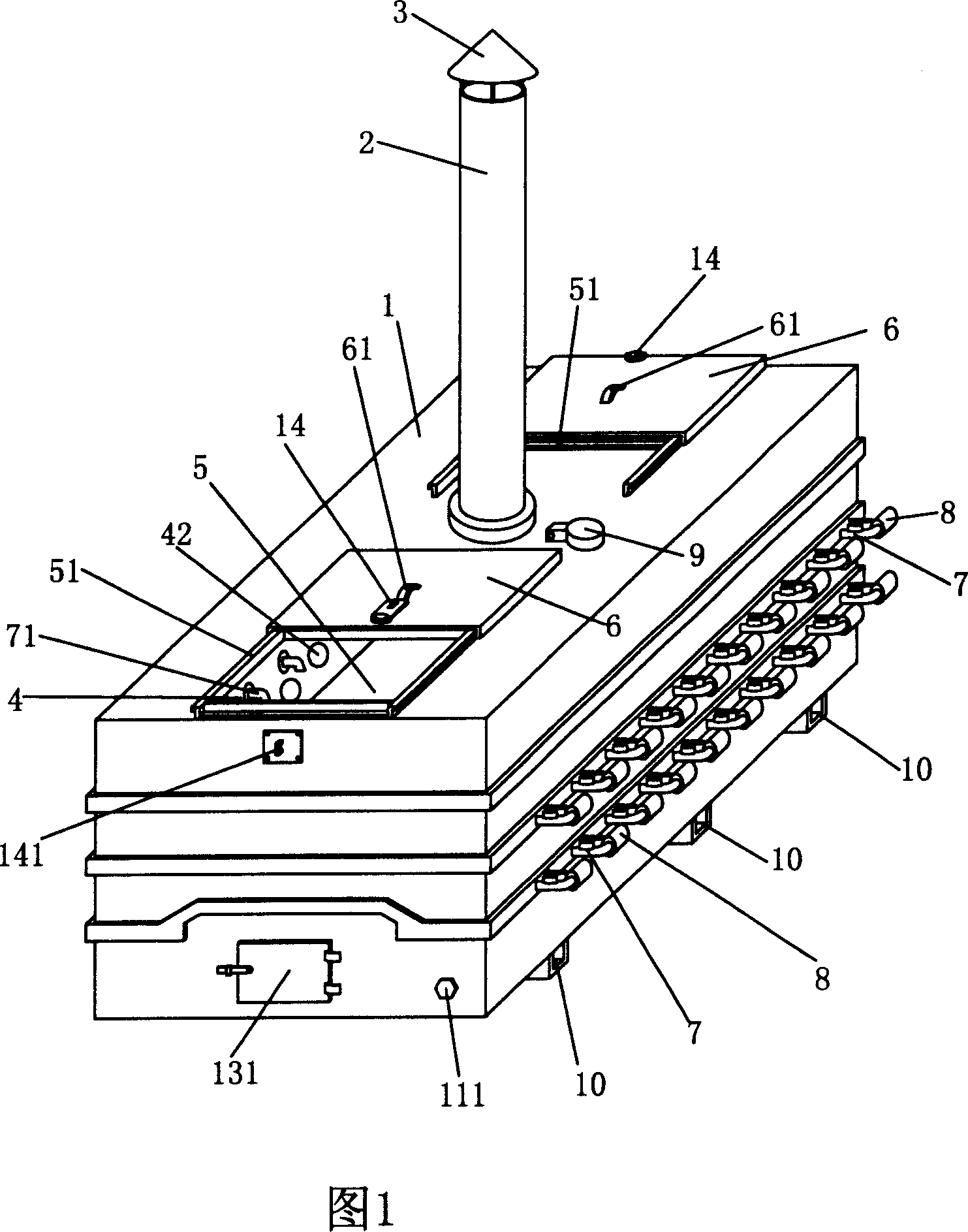

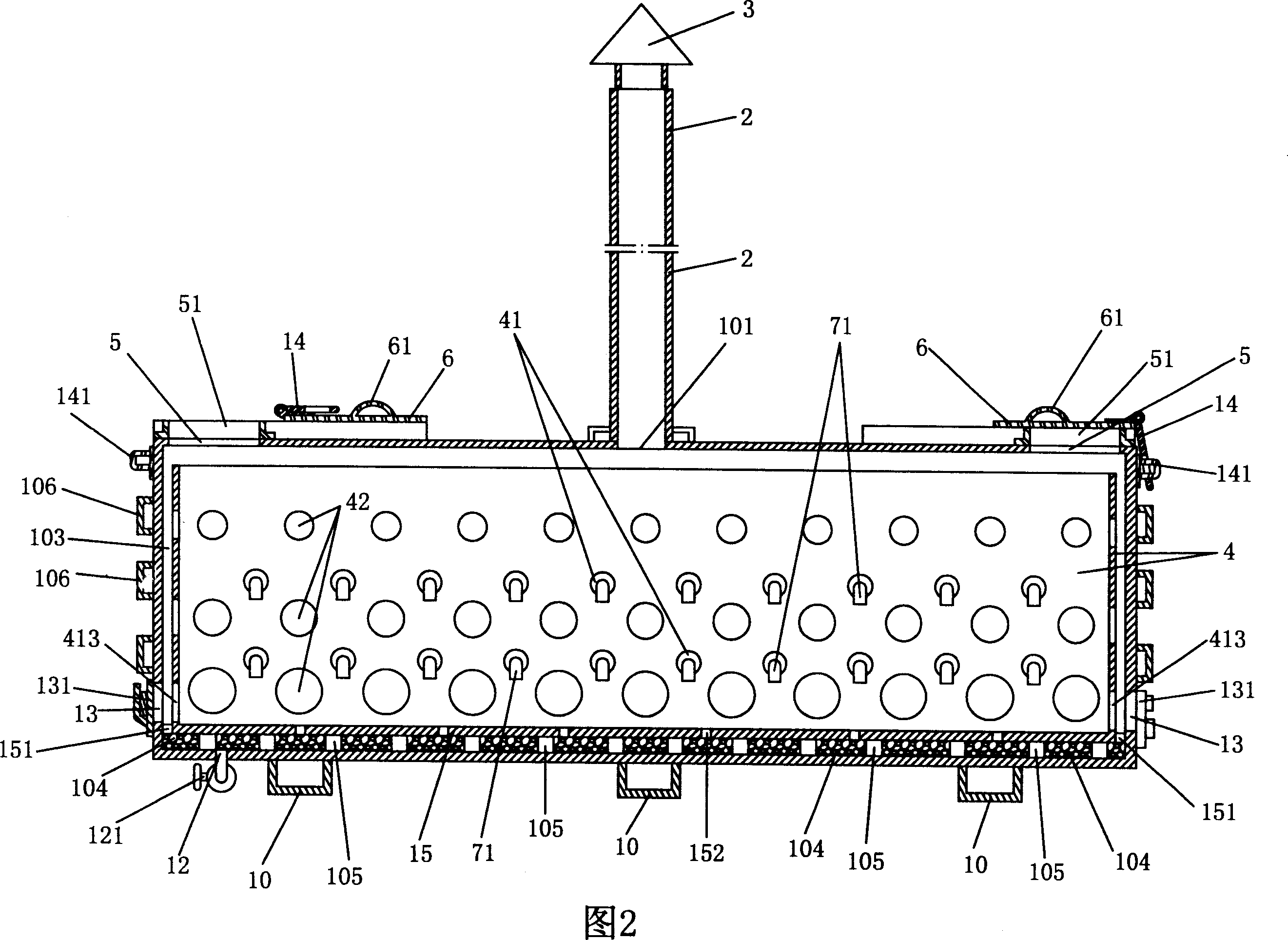

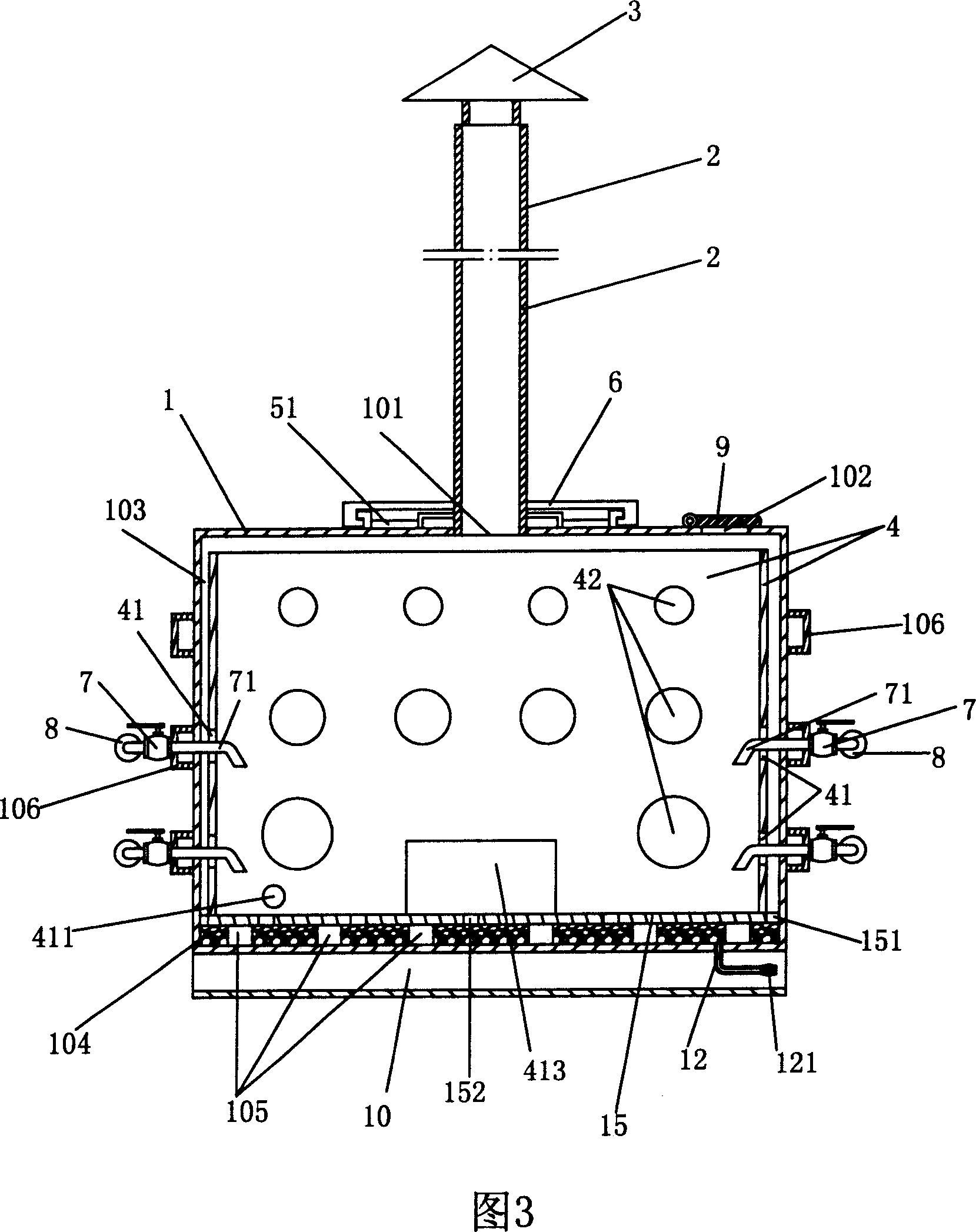

[0034] The structure of a 5 cubic meter capacity embodiment of the thermal decomposer for organic waste of the present invention, which decomposes and treats organic waste with a large capacity, is shown in Figures 1-3. The structural feature of the thermal decomposer for organic waste is that it is suitable for adding organic waste into an iron box and taking out ashes when decomposing and treating organic waste. Its main body is an iron box 1 in a rectangular shape, which is processed and welded with high temperature and high pressure resistant steel plates.

[0035] Iron box 1 top center has exhaust hole 101, and corresponding exhaust hole 10 is equipped with the exhaust tube 2 that thin iron pipe or stainless steel pipe or heat-resistant resin pipe are made. The top of the exhaust pipe 2 is provided with a conical rainproof cover 3 made of thin iron plate or stainless steel sheet. The top of iron case 1 is also provided with a safety hole 102, and the top of iron case 1 i...

Embodiment 2

[0060] The structure of another embodiment of the organic waste thermal decomposer of the present invention is shown in Figures 9-11. The basic structure of the present embodiment is similar to the previous embodiment, but the flow hole 42 ' of each side wall of the heat shield 4 ' adopts a rectangular hole; a smoke-cleaning and deodorizing liquid recoverer is installed on the iron box 1 top. The smoke-cleaning and deodorizing liquid recoverer is composed of stacked primary smoke-cleaning and deodorizing cylinders 90 and secondary smoke-cleaning and deodorizing cylinders 92 , and the exhaust cylinder 2 is inserted into the primary smoke-cleaning and deodorizing cylinders 90 .

[0061] The main body of the present embodiment is a rectangular body iron box 1 welded with steel plates with a relatively long length in the front-to-back direction and a relatively small width in the left-to-right direction.

[0062] Iron box 1 top center has exhaust hole 101, and corresponding exhaus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com