Arsenic polluted water body repairing method and apparatus

A water body remediation and arsenic pollution technology, applied in the field of remediation of arsenic-contaminated water bodies, can solve the problems of increased governance difficulty, large investment, no removal and purification of arsenic-contaminated water bodies, etc., achieving good environmental benefits, low investment and operating costs, The effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

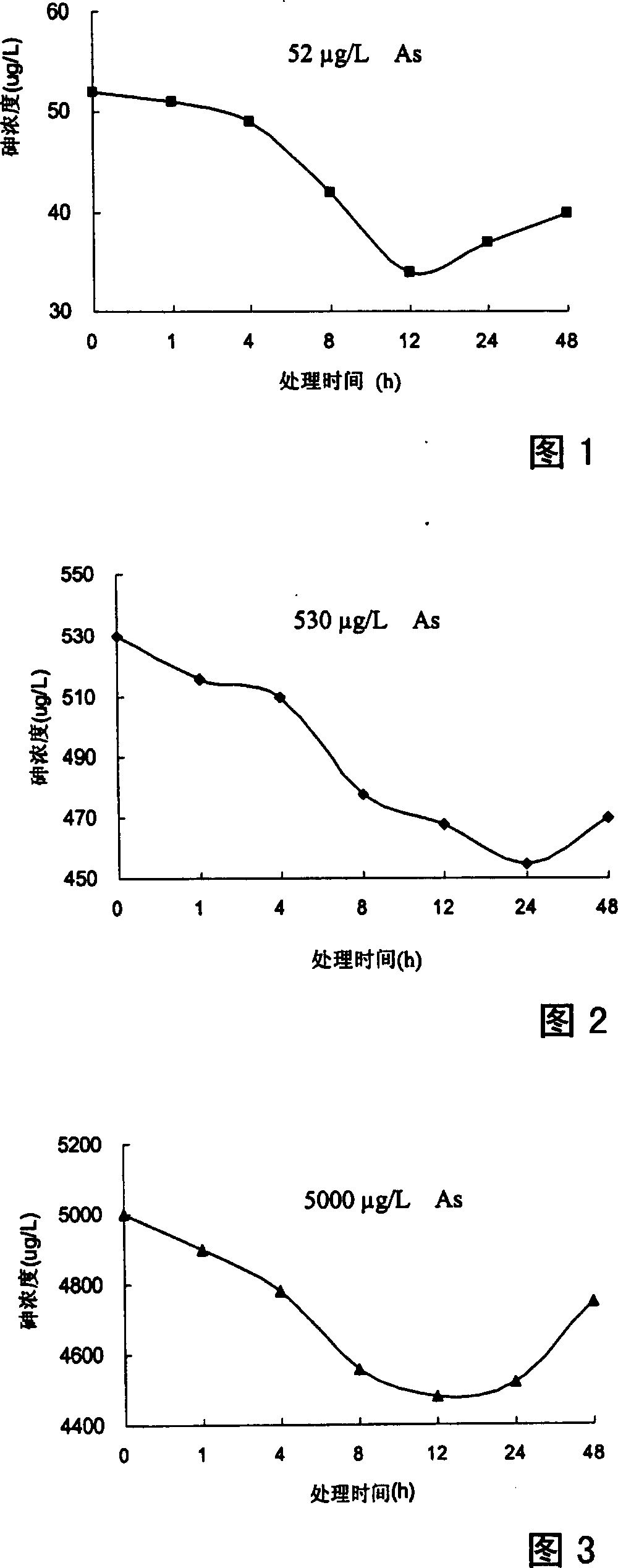

Embodiment 1

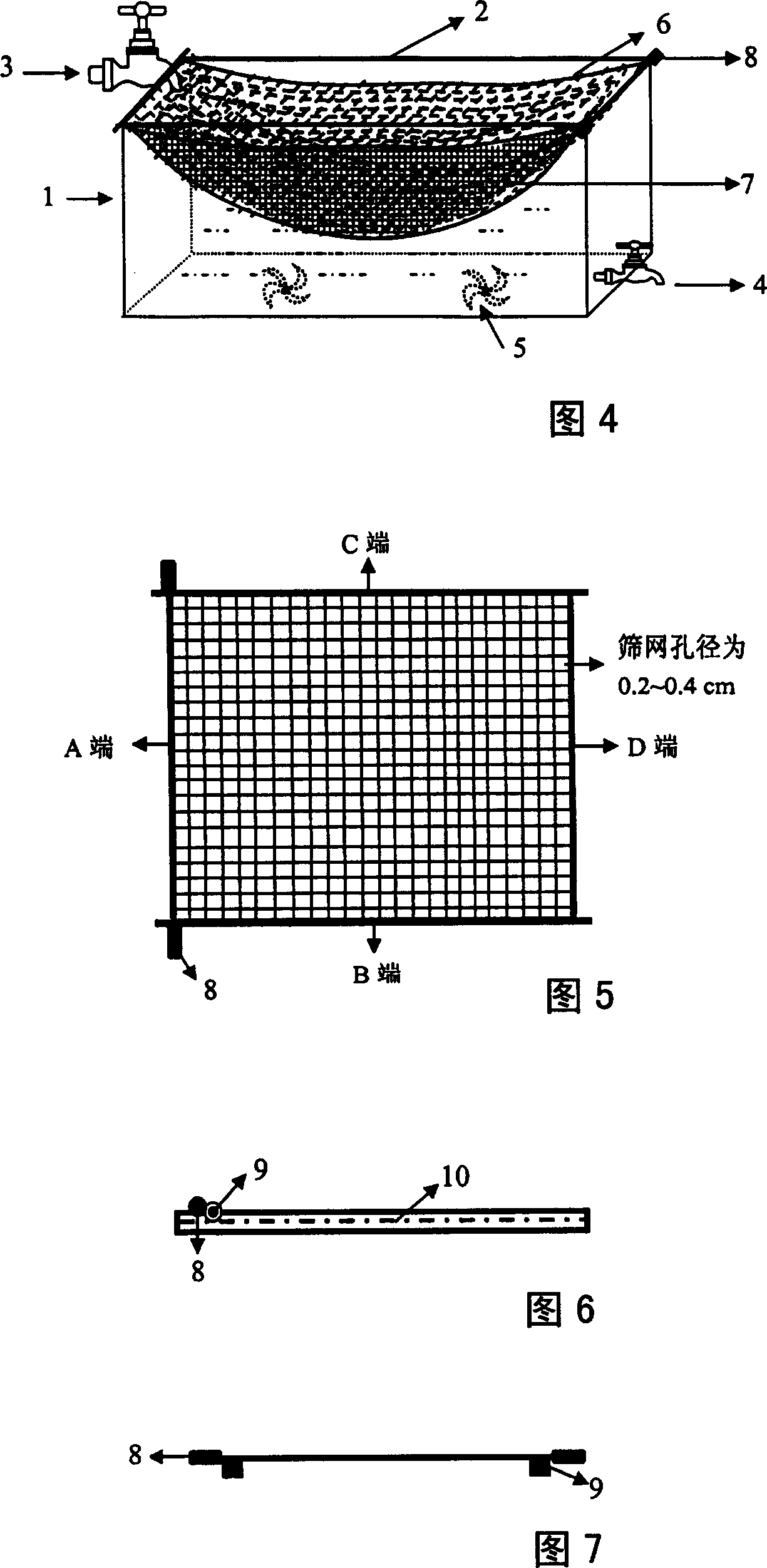

[0032] The arsenic-contaminated water body to be treated (the arsenic concentration is 52 μg / L) enters the water storage tank 1 through the water inlet 3, and the chopped centipede grass feather leaves (length is 1 cm, water: centipede grass=500:1, V / W) are put Put into the middle of the two-layer screen cloth 6 and 7 of pinna holding device, plastic screen cloth and pinnae are all immersed in water then, stir constantly with stirring device 5. Take water samples at 0, 1, 4, 8, 12, 24 and 48 hours to analyze its arsenic concentration, and after 48 hours, slide the A end of the pinna holding device 2 to the D end, and take out the pinnae from the screen Centralized treatment, the treated water is output from the water outlet 4 to the storage tank 1 . As can be seen from Figure 1, between 0-12 hours, the concentration of arsenic in the water decreases with the prolongation of the soaking time of the feather leaves, and reaches the lowest concentration of arsenic in the water at ...

Embodiment 2

[0034] The main operation process is basically the same as that in Example 1, but the arsenic concentration in the water body to be repaired is 530 μg / L. The chopped centipede grass pinnae were immersed in the water body to be treated (water: centipede grass=500:1, V / W), and water samples were taken at 0, 1, 4, 8, 12, 24 and 48 hours to analyze its arsenic concentration, the pinnae were removed from the water body after 48 hours. It can be seen from Figure 2 that the concentration of arsenic in the water decreases with the prolongation of the soaking time of the feather leaves between 0 and 24 hours, and the concentration of arsenic in the water reaches the lowest level at 24 hours, which is 440 μg / L. If the amount of centipede grass pinnata was increased, its arsenic removal efficiency could be further improved. After remediation with centipede grass feather leaves, the arsenic concentration in the polluted water was reduced to below the arsenic concentration (500μg / L, GB 89...

Embodiment 3

[0036] The main operation process is basically the same as in Example 1, but the arsenic concentration in the water body to be repaired is 5000 μg / L (the highest level of arsenic concentration in ordinary industrial sewage). The centipede grass feather leaves were immersed in water with arsenic concentration of 5000 μg / L (water: centipede grass=500:1, V / W), and water samples were taken at different times to analyze the arsenic concentration. It can be seen from Figure 3 that the concentration of arsenic in the water decreases with the extension of the soaking time of the feather leaves between 0 and 12 hours, and the concentration of arsenic in the water reaches the lowest level at 12 hours, which is 4500 μg / L. The removal efficiency of arsenic in the whole process can reach up to 10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com