Method for preparing hypovanadic oxide suspensoid

A technology of vanadium dioxide and suspension, applied in the coating and other directions, can solve the problems of uniformity of dispersion, lack of practical application effect in short time, etc., and achieve the effects of low cost, rheological change and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

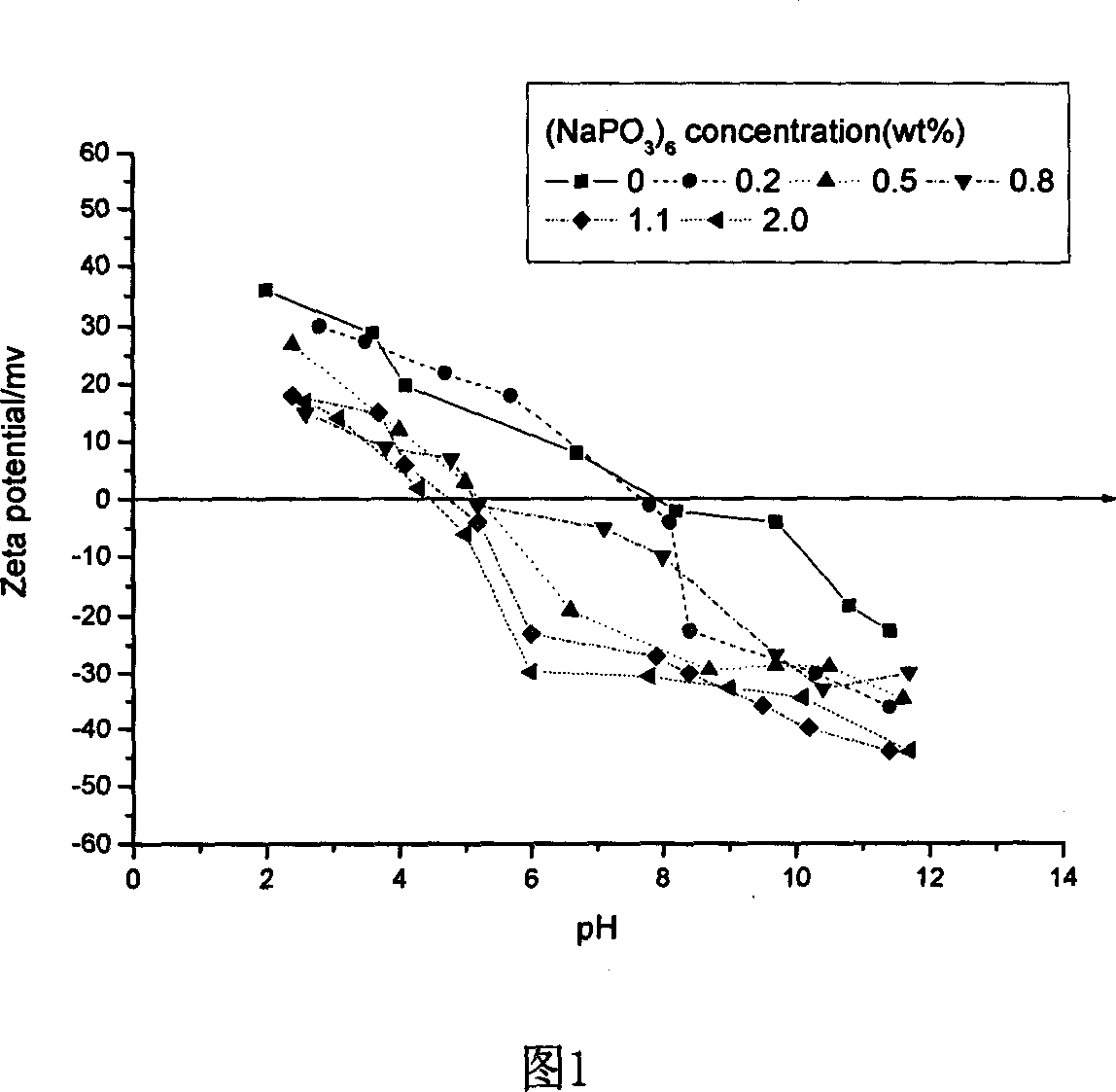

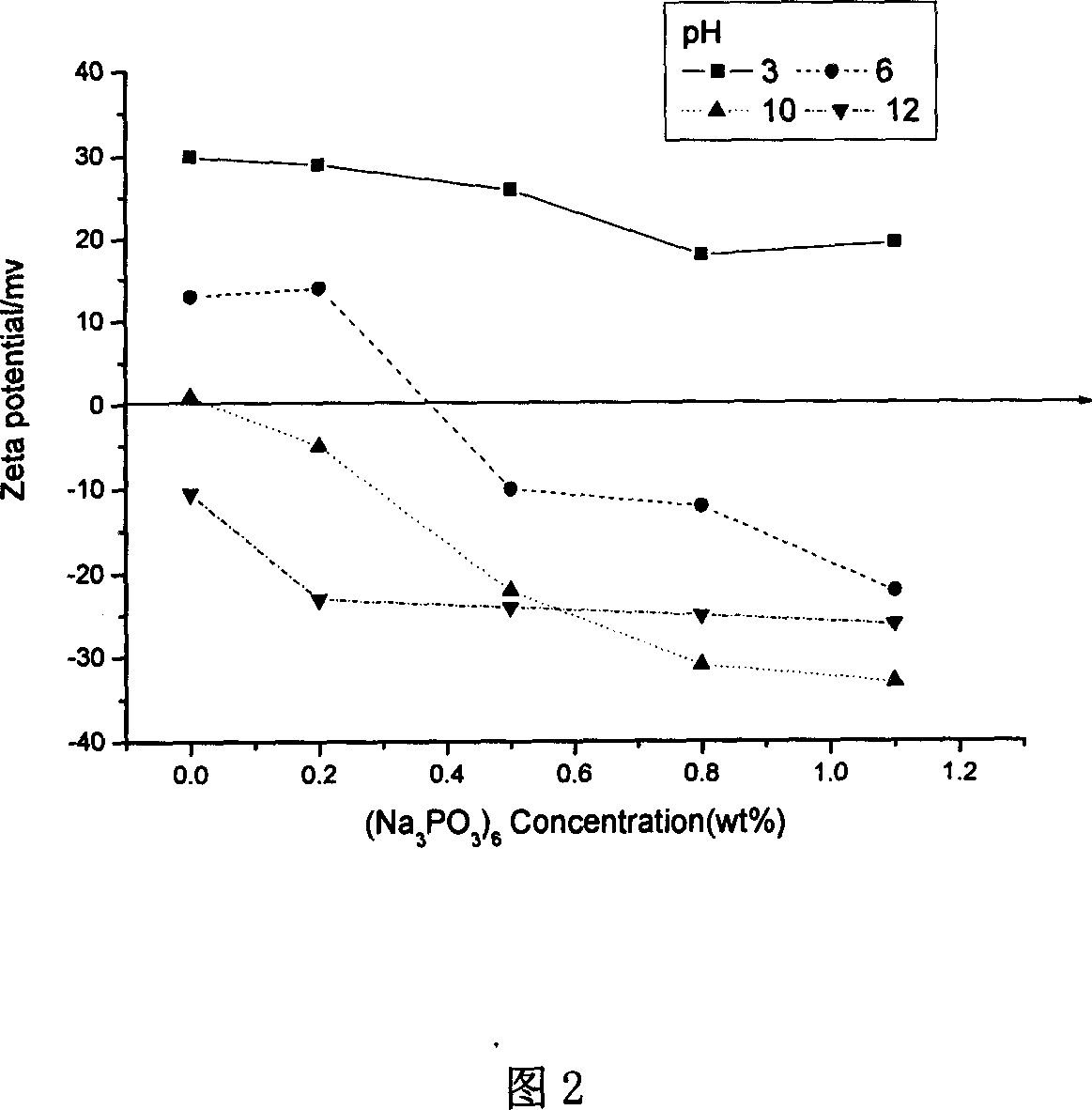

[0023] Weigh 1g nano VO 2 Powder, add 5 drops of wetting agent to wet, then weigh 0.8g (NaPO 3 ) 6 Dissolve 100g of water to prepare a solution, and add the solution to the wetted nano VO 2 In a powder beaker, shear and mix at 5000r / min, adjust the pH value to 10 with ammonia water, stir for 2 hours, and oscillate with ultrasonic waves for 30 minutes to obtain nano VO 2 Powder homogeneous suspension. The zeta potential is shown in Figure 1 and Figure 2.

Embodiment 2

[0025] Take by weighing 2g of nanometer VO2 powder, add 10 drops of wetting agent for wetting, then weigh 1.6g (NaPO3) 6 and dissolve it with 200g of water to make a solution, add the solution to the beaker of the wetted nanometer VO2 powder, Shear and mix at 5000r / min, adjust the pH value to 9 with ammonia water, stir for 2 hours, and oscillate with ultrasonic waves for 30 minutes to obtain a uniform suspension of nano-VO2 powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com