Process and apparatus for utilizing medium-temperature smoke pre-heating combustion-supporting coal gas and air in hot-air stove

A technology of combustion-supporting air and hot blast stoves, applied in furnaces, blast furnaces, heating furnaces, etc., can solve problems such as difficulties in arranging flue gas stoves and pipelines, inability to fully utilize gas enthalpy, poor thermal efficiency of front flue gas stoves, etc., to achieve The effect of shortening the firing time, improving efficiency, and less conversion links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

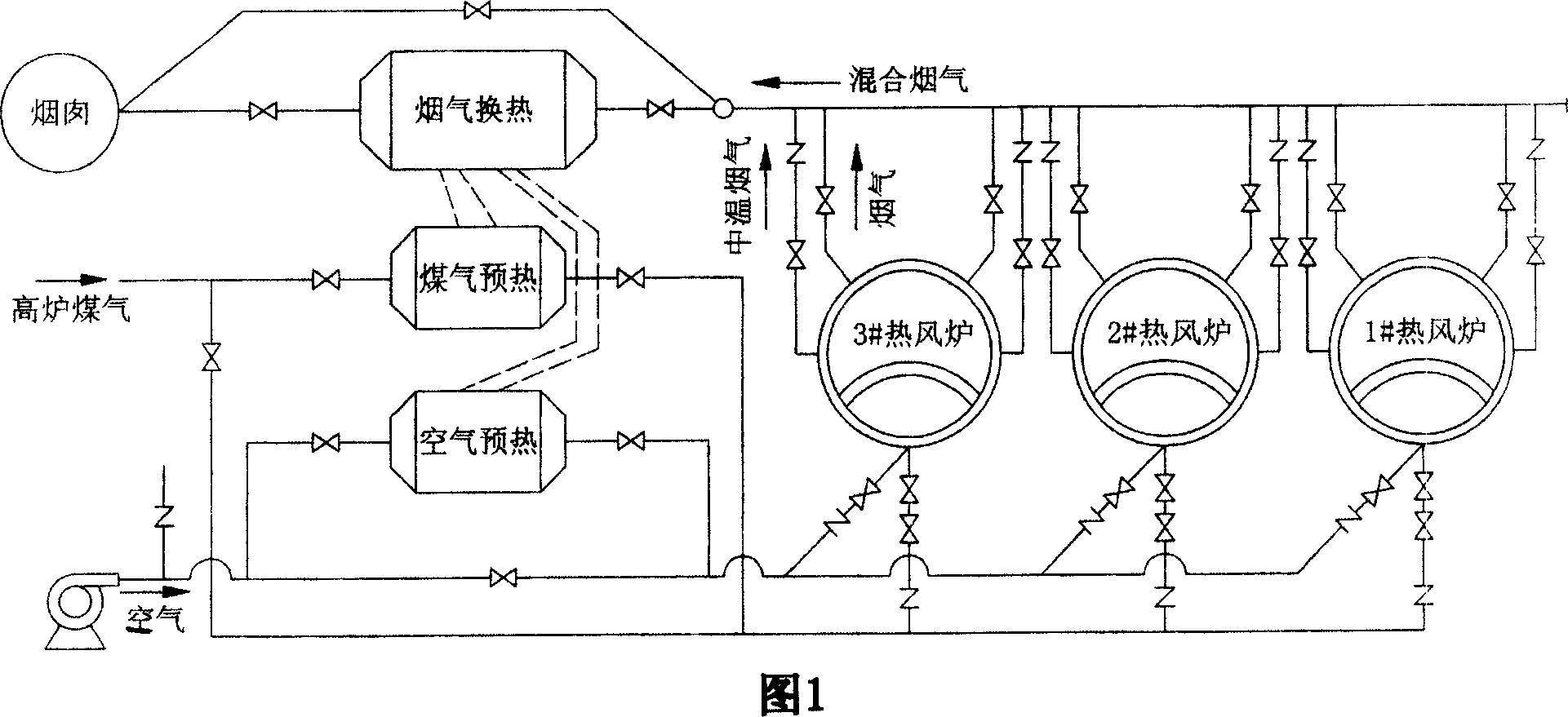

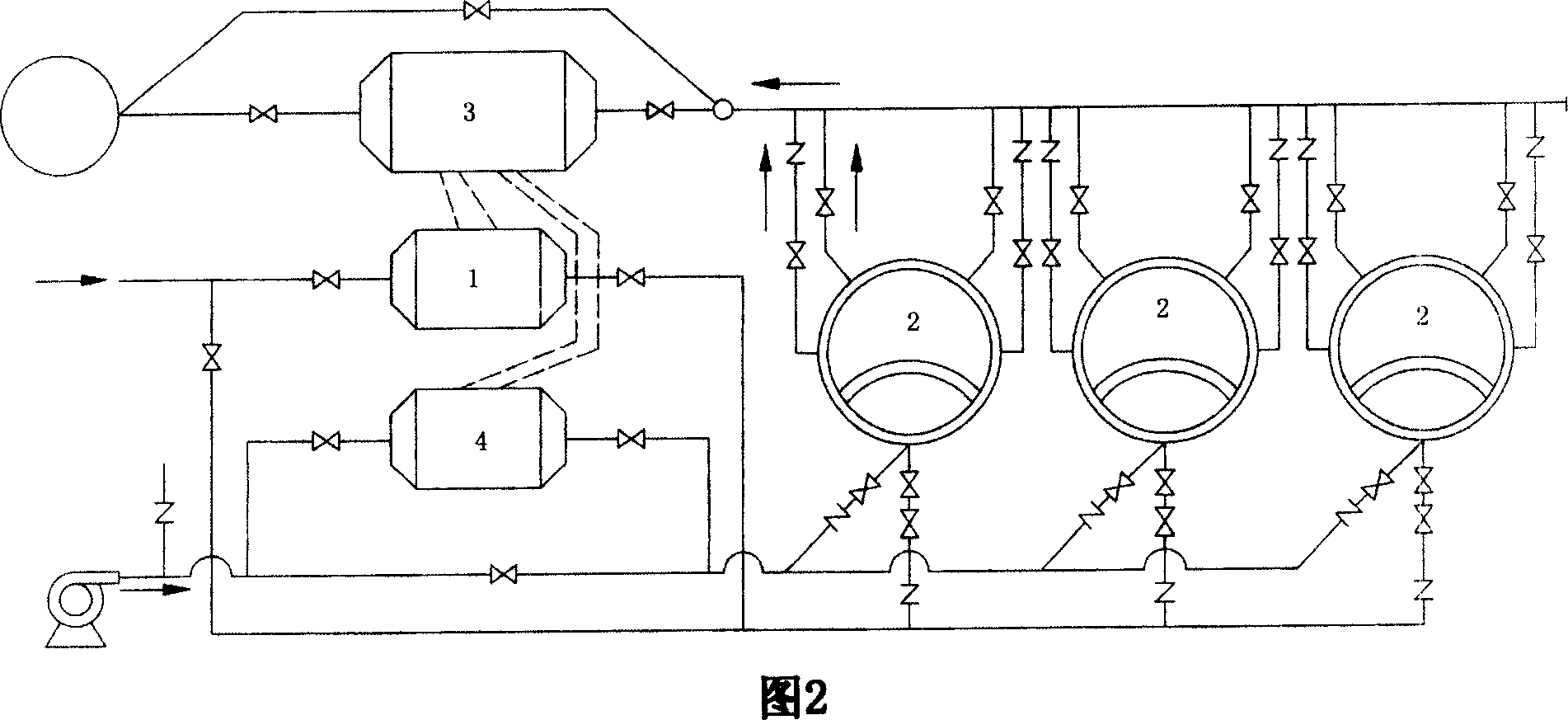

[0012] The technology of using the combustion exhaust gas of the hot blast stove to preheat the combustion air and gas with a heat pipe heat exchanger has been gradually promoted in domestic steel plants in the 1980s and 1990s. Usually, the temperature of the flue gas discharged from the hot blast stove is between 280°C-300°C, the air and gas can be preheated to about 160°C at the same time, and the blast furnace inlet air temperature can be increased by about 70°C. To further improve its preheating effect, the flue gas temperature needs to be increased. The purpose of this process is to effectively increase the flue gas temperature, make the combustion-supporting air and coal gas after heat exchange reach a certain heat enthalpy, increase the combustion temperature of the hot blast stove, and obtain a furnace inlet air temperature of 1250°C. Its process flow is shown in Figure 1.

[0013] First of all, a part of the medium-temperature flue gas from the middle-temperature zon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com