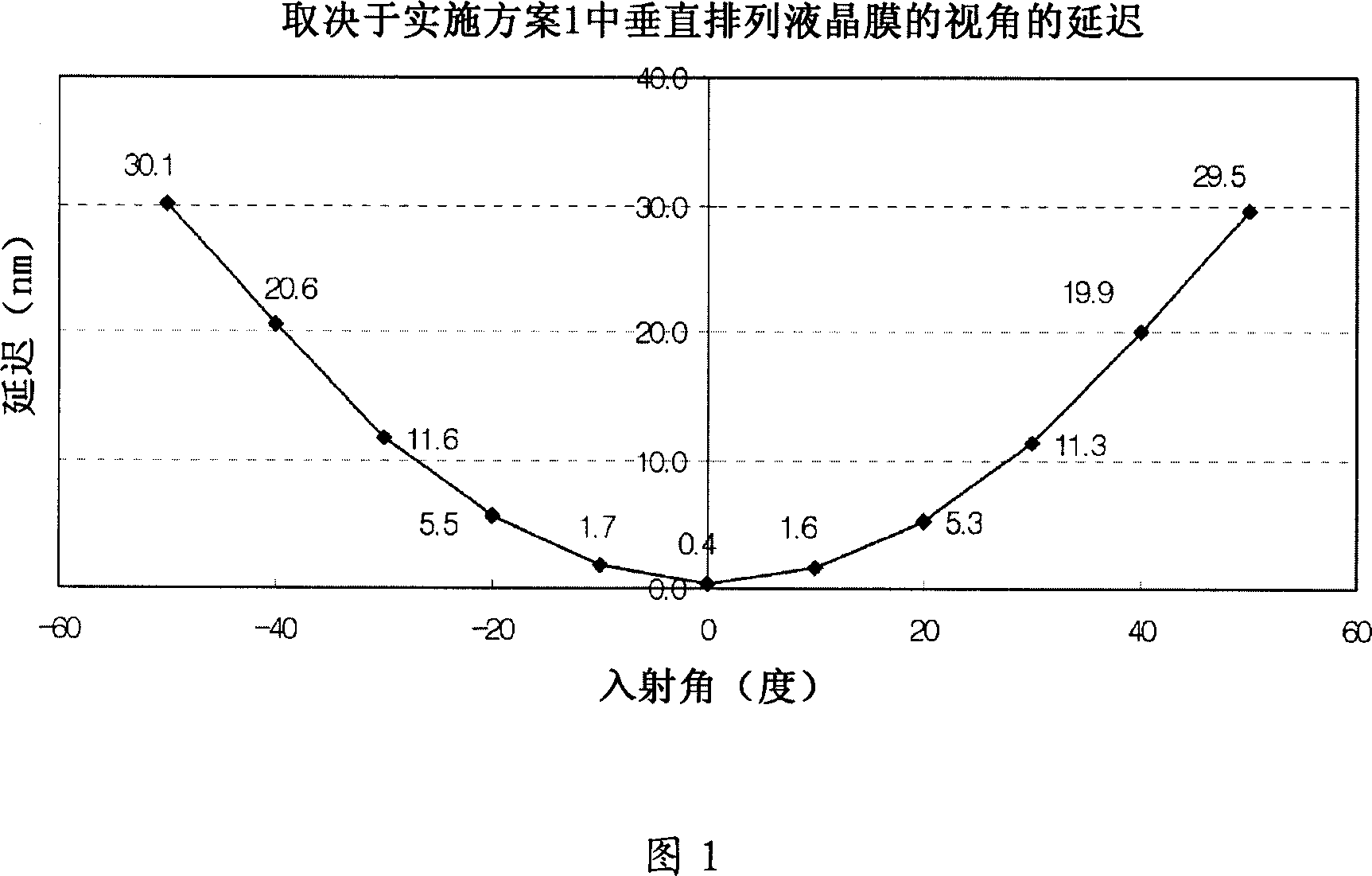

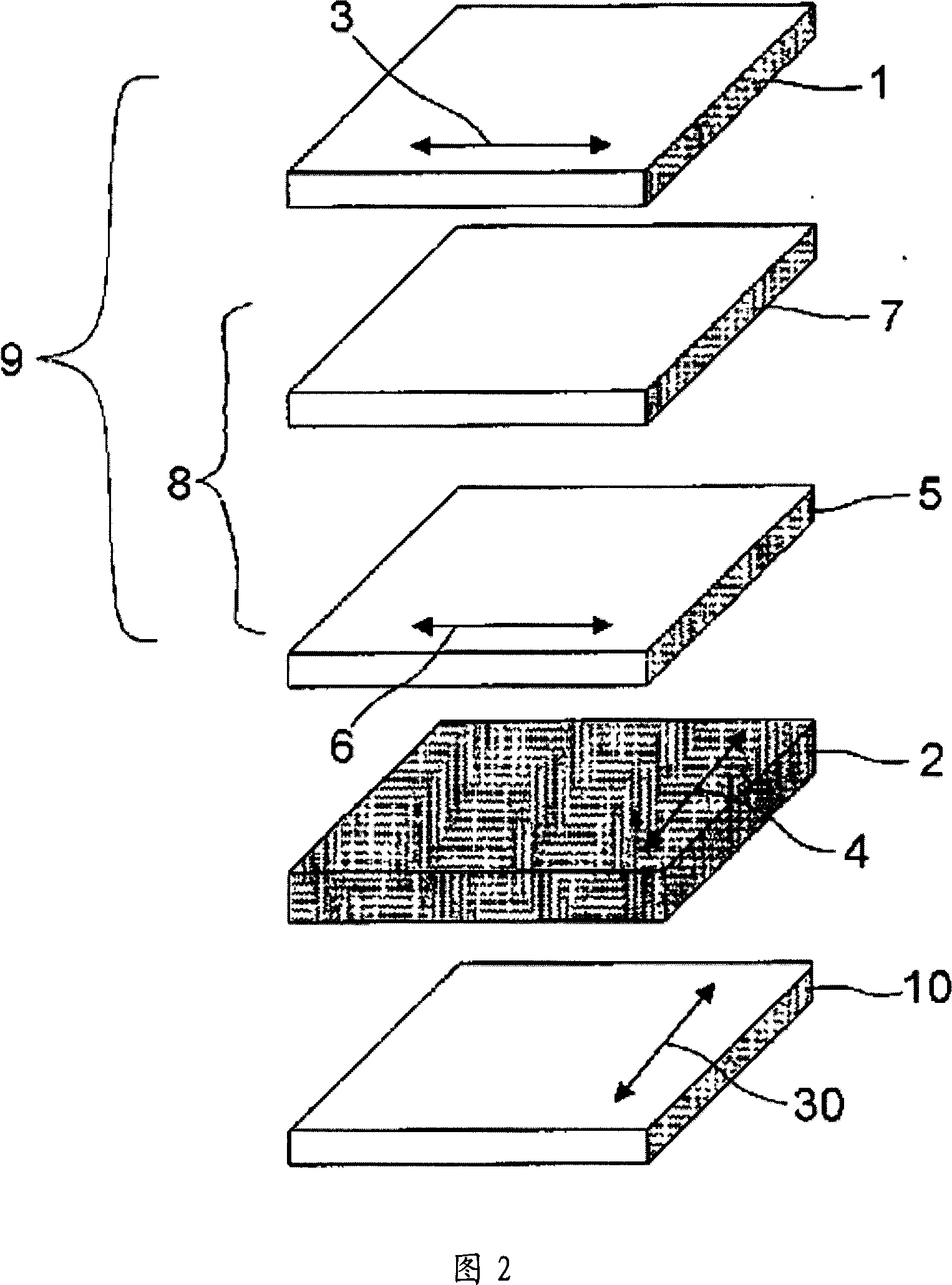

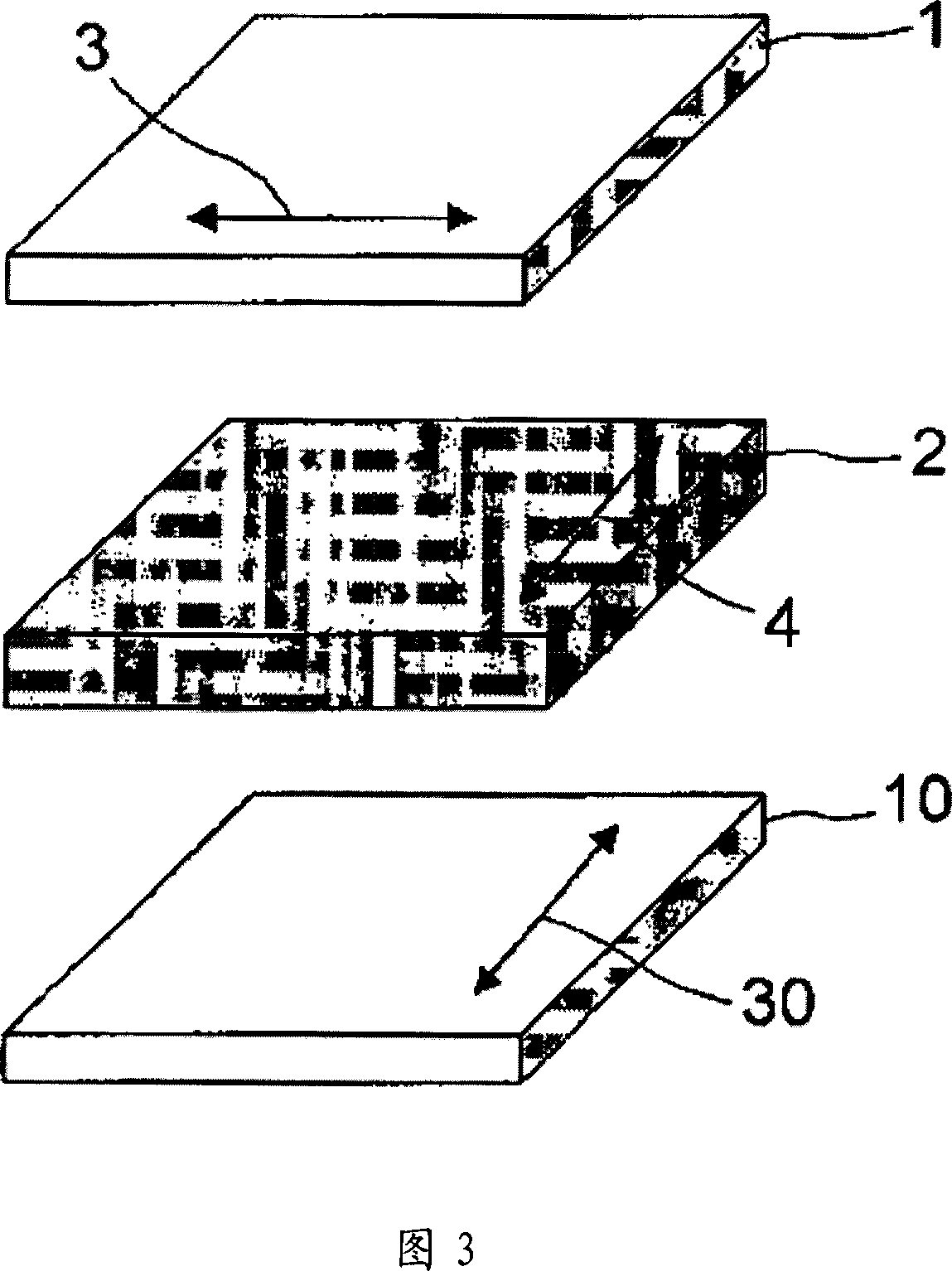

Retardation film having a homeotropic alignment liquid crystal film and method for preparing the same

A technology of vertical alignment and retardation film, applied in liquid crystal materials, chemical instruments and methods, optics, etc., can solve the problems of insufficient thickness reduction, thickening retardation film, difficult continuous process, etc., and achieve viewing angle and color shift properties. Improved, reduced processing time, increased productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0085] In the liquid crystal monomer contained in the polymerizable photoreactive liquid crystal monomer mixed compound used in the embodiment of the present invention, the compound of Chemical Formula 1 is 40 wt%, the compound of Chemical Formula 2 is 27 wt%, and the compound of Chemical Formula 3 is 27 wt%. The solid mixed with a ratio of 6.0 wt% of Irgacure 907 (manufactured by Ciba-Geigy) was melted in a mixed solvent of 70 wt% toluene and 30 wt% cyclohexanone to a solid concentration of 25 wt% to prepare a reactive liquid crystal solution.

[0086] A fluorocarbon-based surfactant Novec (trade name, produced by 3M, USA) FC4430 was added at 1.0 wt% compared to 100 wt% of total solids contained in the total solution.

[0087] After implementing corona discharge treatment on a triacetyl cellulose film (trade name: 80UZ, produced by Fuji of Japan), the liquid crystal solution was coated on the film with a wire rod control coater (No. 4), and The film was kept in a drying oven ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com