Accumulator, accumulator group and their producing method

A battery and battery casing technology, which is applied in secondary battery manufacturing, battery pack components, secondary batteries, etc., can solve problems such as poor heat dissipation performance and difficulty in heat dissipation, improve performance and reliability, and ease cooling problems. The effect of shortening the distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

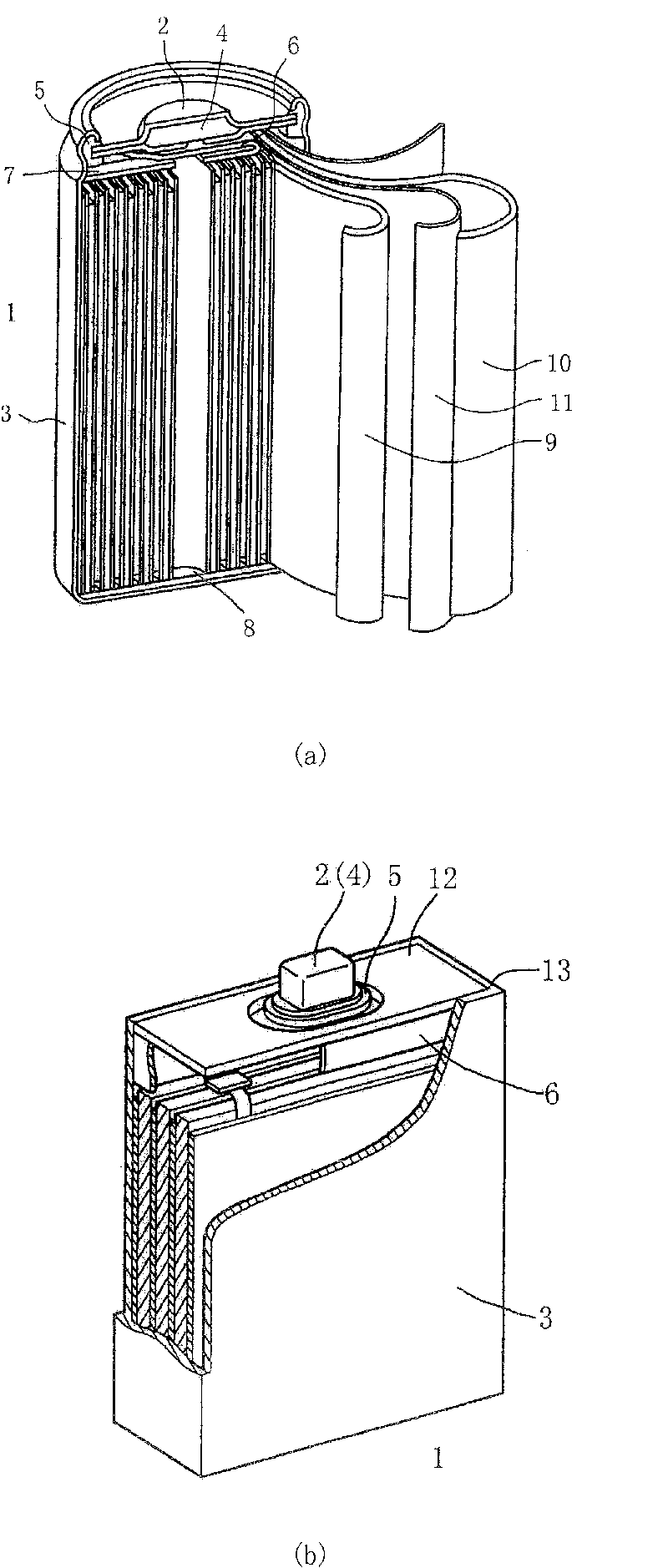

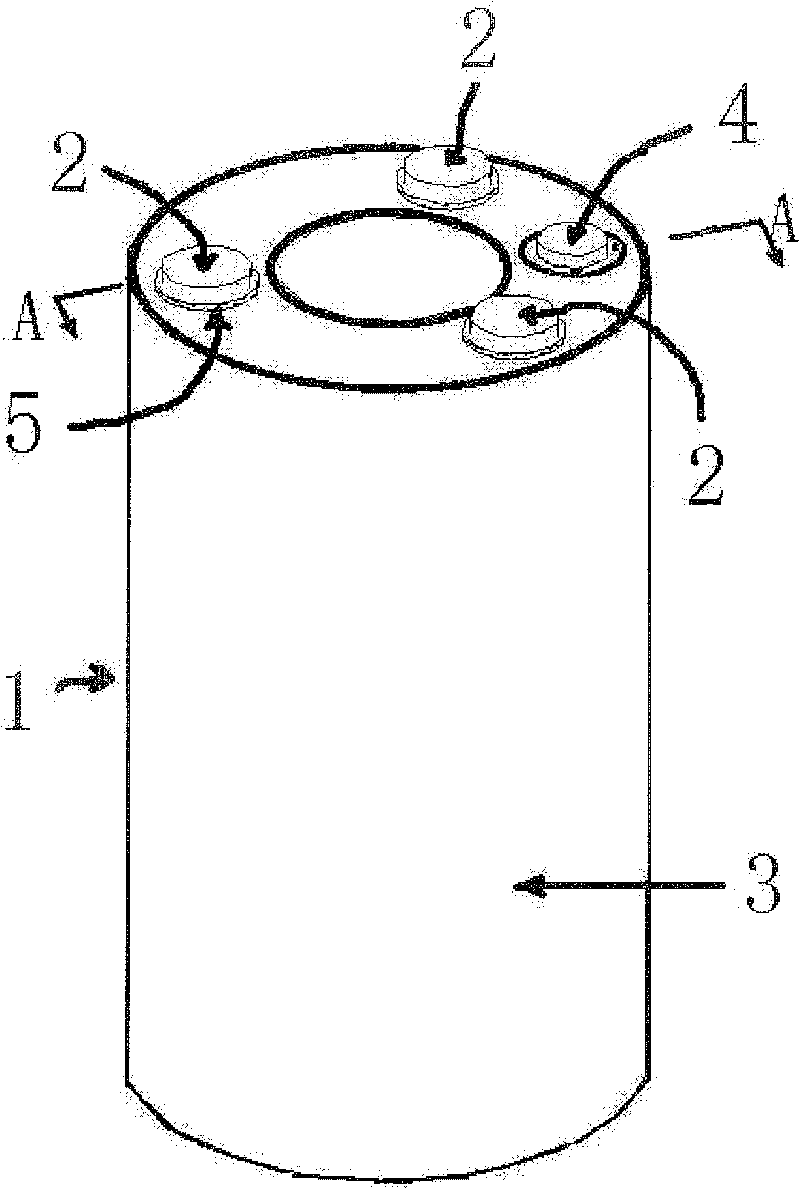

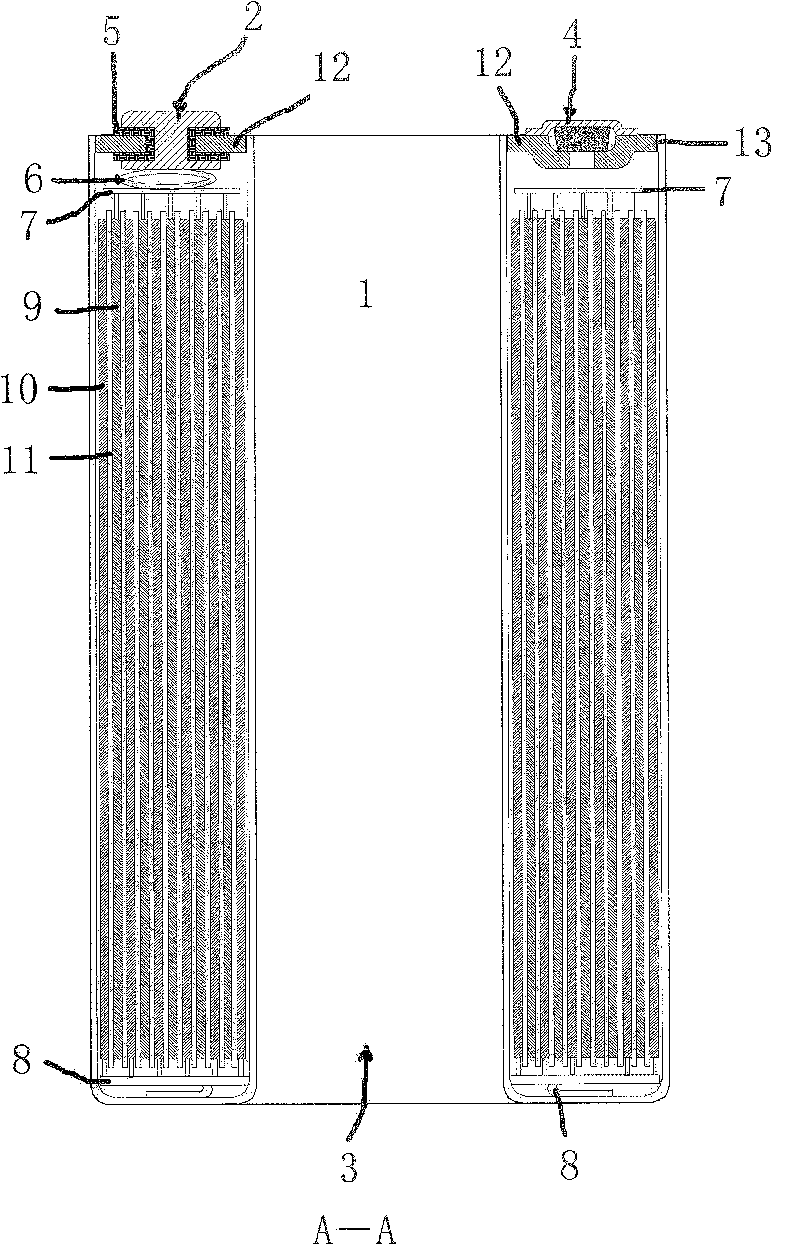

[0046] The battery 1 with a metal case looks like figure 2 As shown, the outside is cylindrical, and the inside is also cylindrical. There are three positive terminals 2 on the top, and the battery shell 3 is used as the negative terminal. There is also a safety valve 4 on the top. Looking down from the top, the battery 1 is as Figure 4 As shown, it is in the form of a ring, and the three positive terminals are evenly distributed on the battery sealing plate 12. The safety valve 4 can be a safety valve commonly used in alkaline sealed batteries at present, and the sealing plate 12 and the battery case 3 are welded by laser. The method is connected and sealed. Since the opening of the battery case is in the form of a ring, there are two welding seams, inner and outer. 13. The internal structure of the battery 1 is as follows: image 3Since the sealing cover 12 is electrically connected to the battery case 3, an insulating pad 5 made of plastic is used to realize electrical in...

Embodiment 2

[0055] Such as Figure 5 As shown, except that the cross-sectional shape of the battery is a "back" shape, the rest are the same as in Example 1.

[0056] When batteries in this embodiment form a battery pack, the space utilization rate can be further improved under the premise of ensuring good heat dissipation.

Embodiment 3

[0058] Such as Image 6 As shown, except that the cross-section of the battery is hexagonal and different in shape, the rest are the same as in Example 1.

[0059] The battery of this embodiment combines the advantages of Embodiment 1 and Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com