Composite type clearing agent in use for refining sugar, and preparation method

A clarifying agent and composite technology, applied in the fields of application, sucrose production, sugar production, etc., to achieve the effects of reduced dosage, simple manufacturing method, and high clarification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

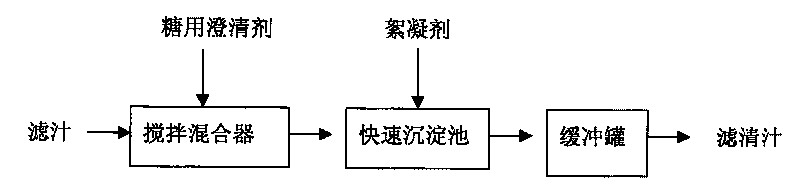

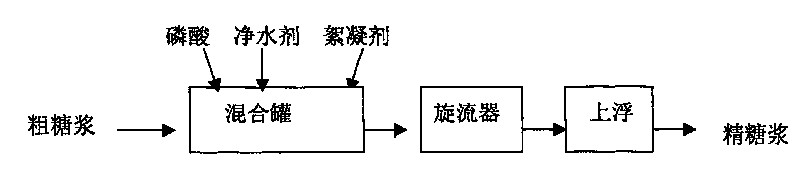

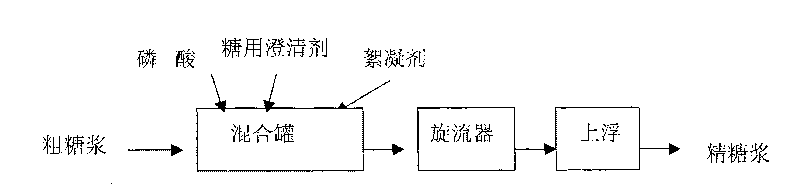

Method used

Image

Examples

Embodiment 1

[0030] Step 1, dissolving dimethyl diallyl ammonium chloride homopolymer in water into a solution with a concentration of 10%, and taking 8 kg in a storage tank;

[0031] Step 2, take 30 grams of 300 mesh diatoms and 10 kilograms of 300 mesh perlite powder in a mixer, and stir continuously at a speed of 100 rpm, and simultaneously mix 8 kilograms of 10% polydimethyl Slowly add the dienyl ammonium chloride solution to the powder, and continue stirring for 15 minutes after the addition of the polydimethyldiallyl ammonium chloride solution;

[0032] Step 3, then 150 kilograms of polyaluminum chloride (basicity is 85%, Al 2 o 3 Content is 30%) join in the mixer;

[0033] Step 4, at last 5 kilograms of chitosan with a deacetylation degree of 85% are added in the mixer, then continue to stir and stop after 30 minutes;

[0034] Step 5, take out the mixture from the mixer, put it into a bag and pack it to obtain the compound sugar clarifying agent-1 of the present invention.

[00...

Embodiment 2

[0046] Step 1, get 7.5 kilograms of concentration and be that the copolymer of 10% dimethyl diallyl ammonium chloride and acrylamide and 7.5 kilograms contain the aqueous solution of 10% chitosan quaternary ammonium salt in storage tank and mix to become organic Polymer material mixture;

[0047] Step 2, get 30 kilograms of 300 mesh diatomite, 15 kilograms of 300 mesh perlite powder and 21 kilograms of 300 mesh clay in a mixer, and keep stirring under the condition of 100 rpm at a rotating speed; Slowly add the molecular mixture into the mixer in step 2 of the powder, and continue stirring for 15 minutes;

[0048] Step 3, then 75 kilograms of polyaluminum chloride (basicity is 85%, Al 2 o 3 content is 30%) into the mixer;

[0049] Step 4, finally adding 5 kilograms of chitosan with a degree of deacetylation of 90% into the mixer and continuing to stir after 30 minutes;

[0050] Step 5, take out the mixture from the mixer, put it into a bag and pack it to obtain the compoun...

Embodiment 3

[0066] Step 1, dissolving the dimethyldienyl ammonium chloride homopolymer in water into a solution with a concentration of 10%, and taking 10 kg in a storage tank;

[0067] Step 2, take 15 kilograms of 400 mesh diatomite in a mixer, slowly add 10 kilograms of 10% polydimethyldienyl ammonium chloride solution to the powder at a speed of 100 rpm, After adding the polydimethyldiallyl ammonium chloride solution, continue to stir for 15 minutes;

[0068] Step 3, then 165 kilograms of polyaluminum chloride (basicity is 85%, Al 2 o 3 Content is 30%) join in the mixer;

[0069] Step 4, finally 15 μg of chitosan with a degree of deacetylation of 85% is added to the mixer, then continue to stir and stop after 30 minutes;

[0070] Step 5, take out the mixture from the mixer, pack it into a bag to obtain the compound sugar clarifying agent-3 of the present invention.

[0071] The weight percent content of each component is in this example:

[0072] Polyaluminum Chloride 82.5%,

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com