Method, apparatus and system for transferring heat

A heat transfer and geothermal technology, applied in the field of heat transfer, devices and systems, can solve problems such as waste of heat energy, achieve the effect of system and operation simplification, and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

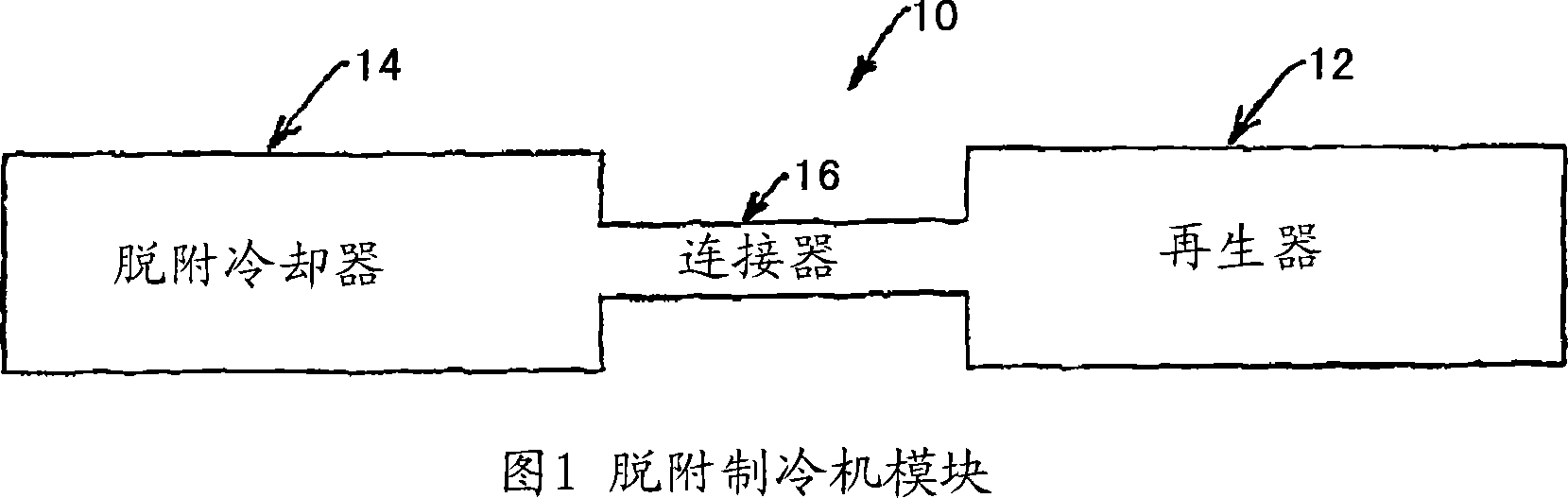

[0072] The desorption cooler module in Figure 1 was tested and calculated to obtain an energy efficiency coefficient (COP) of 0.22 (refer to the system in US5522228 with a theoretical COP lower than 0.054). This calculation is made under the condition that the system in US5522228 is used as the basis for the following items.

[0073] Based on the system in US5522228, an assumption is made that each container 11 and 10 contains 100g of zeolite and carbon. The energy required to heat carbon from 0°C to 30°C is estimated to be about 2.1kJ. The energy required to heat the zeolite from 45°C to 70°C and from 70°C to 200°C is estimated to be approximately 1.75kJ and 9.1kJ, respectively. The energy taken away due to cooling from -40°C to -50°C is estimated to be about 0.7kJ. Ignoring the energy required for zeolite cooling from 190°C to 45°C, from 200°C to 190°C, and carbon from -50°C to 0°C (that is, due to the possibility of recycling energy from cooling material to heating material), C...

example 2

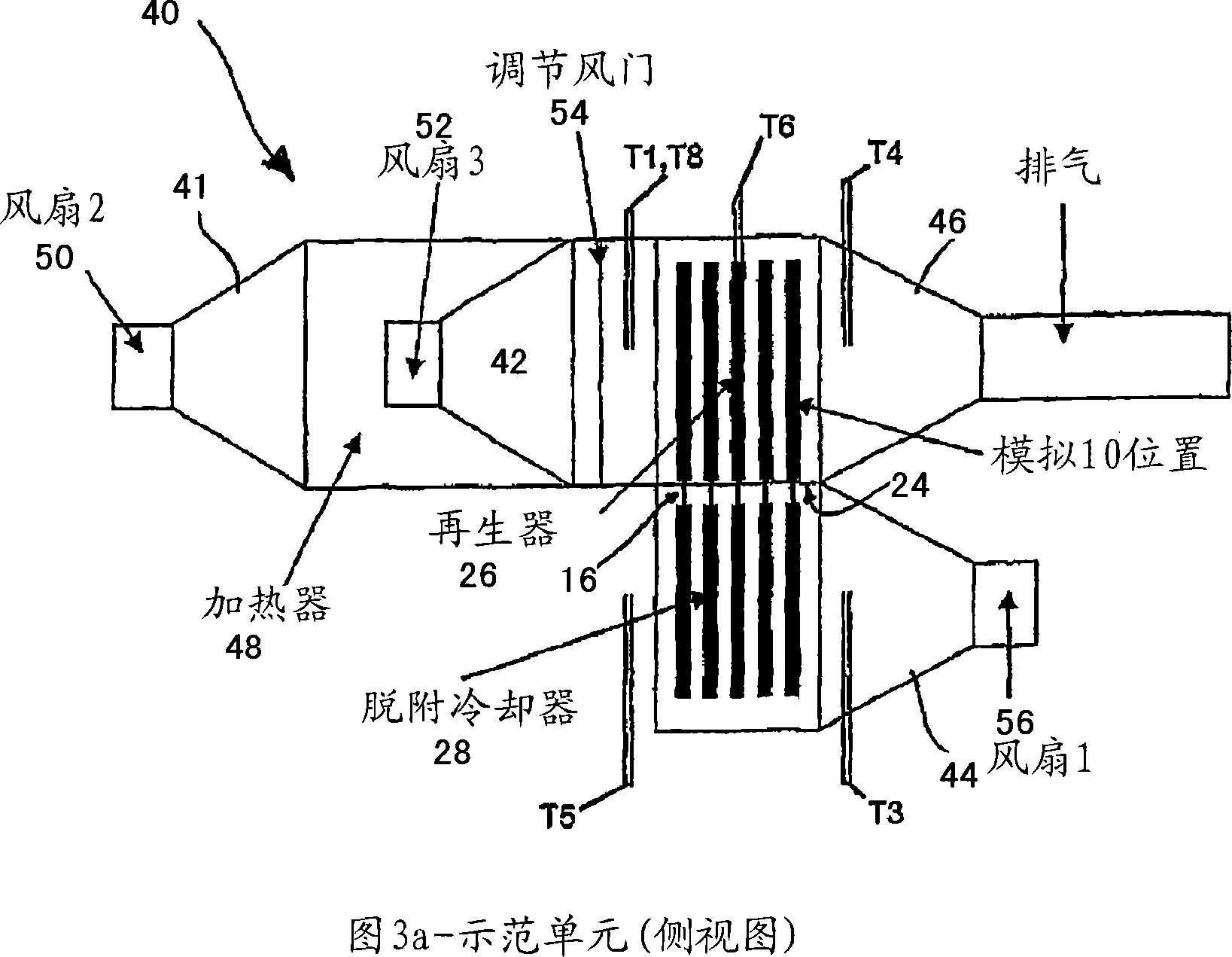

[0076] A demonstration unit was improved and tested for evaluation:

[0077] 1. The temperature of the regenerator is optimized;

[0078] 2. Cooling capacity, calculated in KJ;

[0079] 3. Energy efficiency coefficient (COP) or efficiency;

[0080] 4. The range of temperature drop reached in one cycle;

[0081] 5. Any impact of time on performance;

[0082] 6. The possibility of changing the heating and cooling rate or time to design an optimal time cycle for commercial systems.

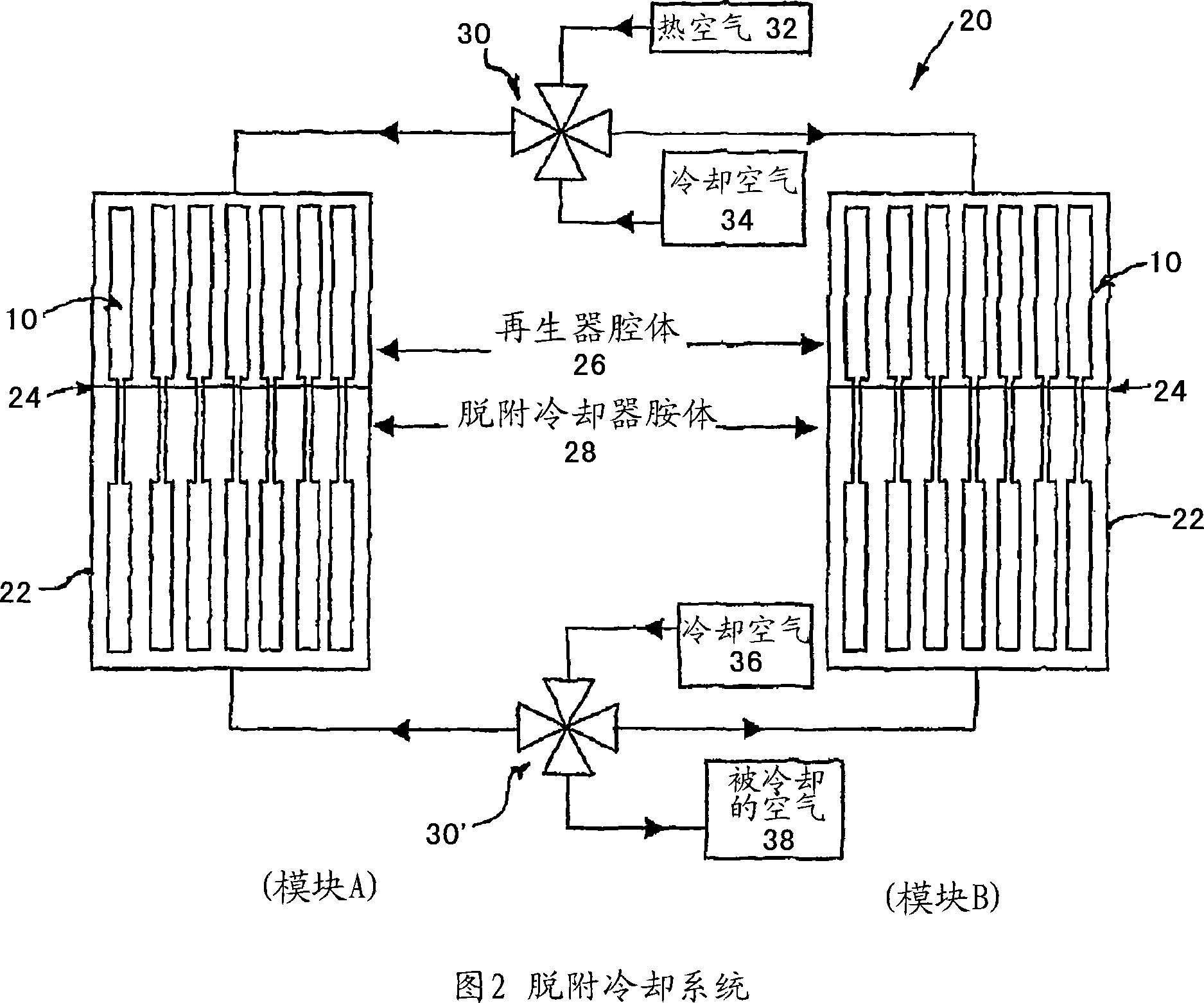

[0083] The schematic diagram of the exemplary unit is depicted in FIGS. 3a and 3b, where the same reference numerals denote the same or similar parts as in FIGS. 1 and 2. The exemplary unit 40 includes one of the two modules A and B shown and described in FIG. 2.

[0084] Conduct research and optimization of one of the modules to collect relevant performance and design data, and therefore can be proportionally increased and decreased in the design of commercial modules.

[0085] The demonstration unit in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com