Process for producing hydrotalcite-like layered hydroxide

A layered hydroxide and production method technology, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as complex process, low yield, pollution, etc., and achieve high-quality, high-yield effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

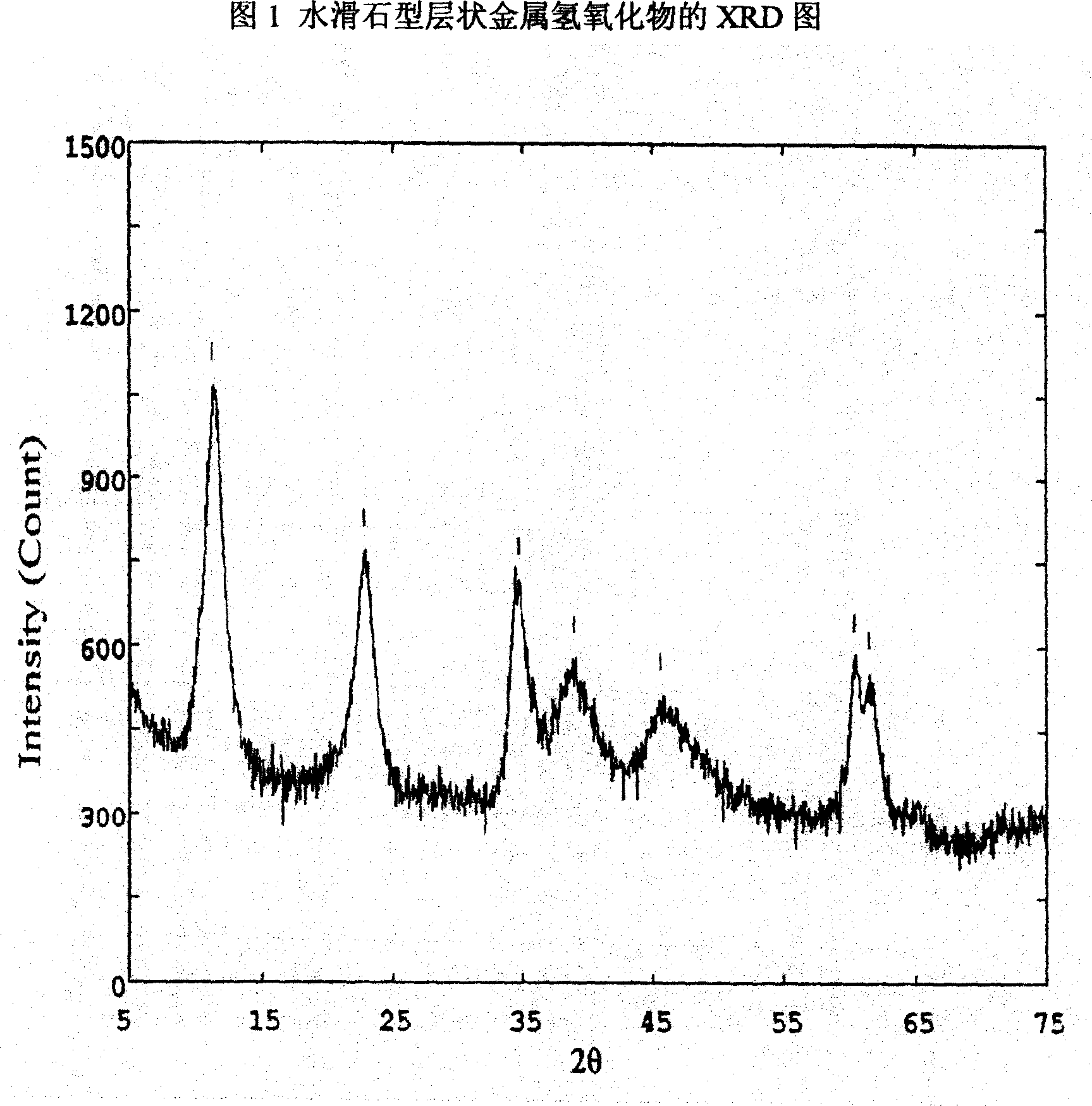

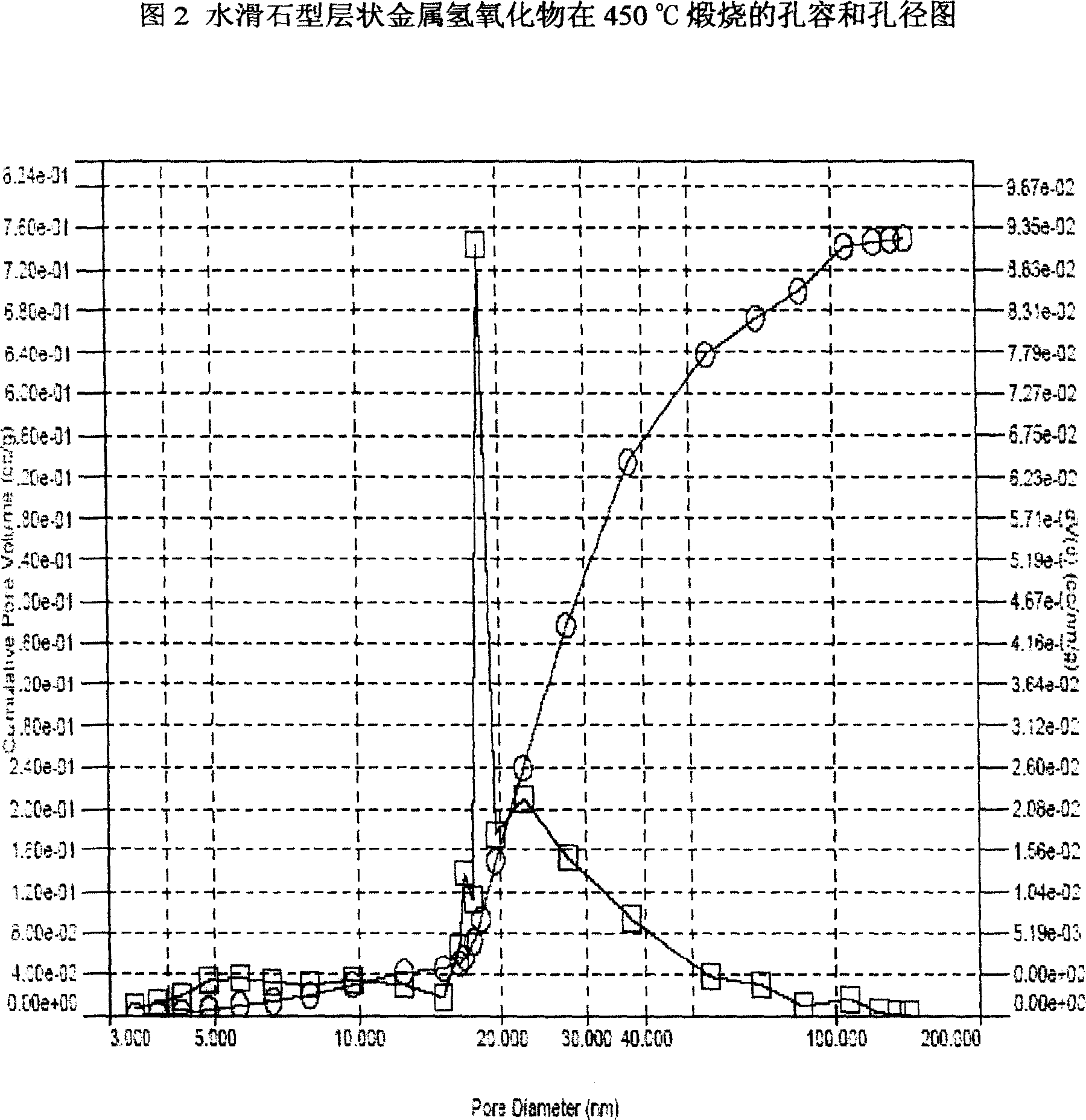

[0022] 1536.2 grams of industrial magnesium nitrate, 748.5 grams of industrial aluminum nitrate, dissolved in deionized water to a specific gravity of 1.116; 583 grams of sodium hydroxide, 1272 grams of sodium carbonate, dissolved in deionized water to a specific gravity of 1.147. Under stirring conditions, the two solutions were neutralized at a flow rate of 5L / min, the temperature of the precipitation solution was 70°C, the pH was adjusted to 7.3, the precipitation time was controlled at 3 hours, the precipitation was completed and aged for 30 minutes, and the product was filtered and washed , dried to obtain a white powder. The XRD test results show (as shown in Figure 1), the product is a layered material with a specific surface area of 80m 2 / g, the pore volume is 0.40cc / g. In the waste liquid generated, Al 2 o 3 The concentration of MgO is 0, and the concentration of MgO is 0.001%.

Embodiment 2

[0024] 5120 grams of industrial magnesium nitrate, 725 grams of industrial aluminum sulfate, dissolved in deionized water to a specific gravity of 1.316; 926.5 grams of sodium hydroxide, 170.4 grams of sodium carbonate, dissolved in deionized water to a specific gravity of 1.247. Under stirring conditions, the two solutions were neutralized at a flow rate of 10L / min. The temperature of the precipitation solution was 70°C, and the pH was adjusted to 11.1. The precipitation was completed and aged for 160 minutes. The product was filtered, washed, and dried to obtain a white powder. body. The XRD test results show that the product is a layered material with a specific surface of 60m 2 / g, the pore volume is 0.50cc / g. In the waste liquid generated, Al 2 o 3 The concentration of MgO is 0, and the concentration of MgO is 0.0012%.

Embodiment 3

[0026] 3120 grams of industrial magnesium nitrate, 725 grams of industrial aluminum sulfate, dissolved in deionized water to a specific gravity of 1.316; 626.5 grams of sodium hydroxide, 170 grams of sodium carbonate, dissolved in deionized water to a specific gravity of 1.247. Under stirring conditions, the two solutions were neutralized at a flow rate of 10L / min. The temperature of the precipitation solution was 70°C, and the pH was adjusted to 9.1. The precipitation was completed and aged for 160 minutes. The product was filtered, washed, and dried to obtain a white powder. body. The XRD test results show that the product is a layered material with a specific surface of 60m 2 / g, the pore volume is 0.50cc / g. In the waste liquid generated, Al 2 o 3 The concentration of MgO is 0.0001%, and the concentration of MgO is 0.0015%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com