Method and apparatus for testing stress of cavern wall

A technology of stress testing and stress relief method, which is applied in the direction of measuring devices, electromagnetic measuring devices, mining devices, etc., can solve the problems that the accuracy of measurement does not match the actual situation, the error of measurement results is large, and the measurement results interfere with each other. To achieve the effect of accurate and reliable measurement, guaranteed precision, simple and practical method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

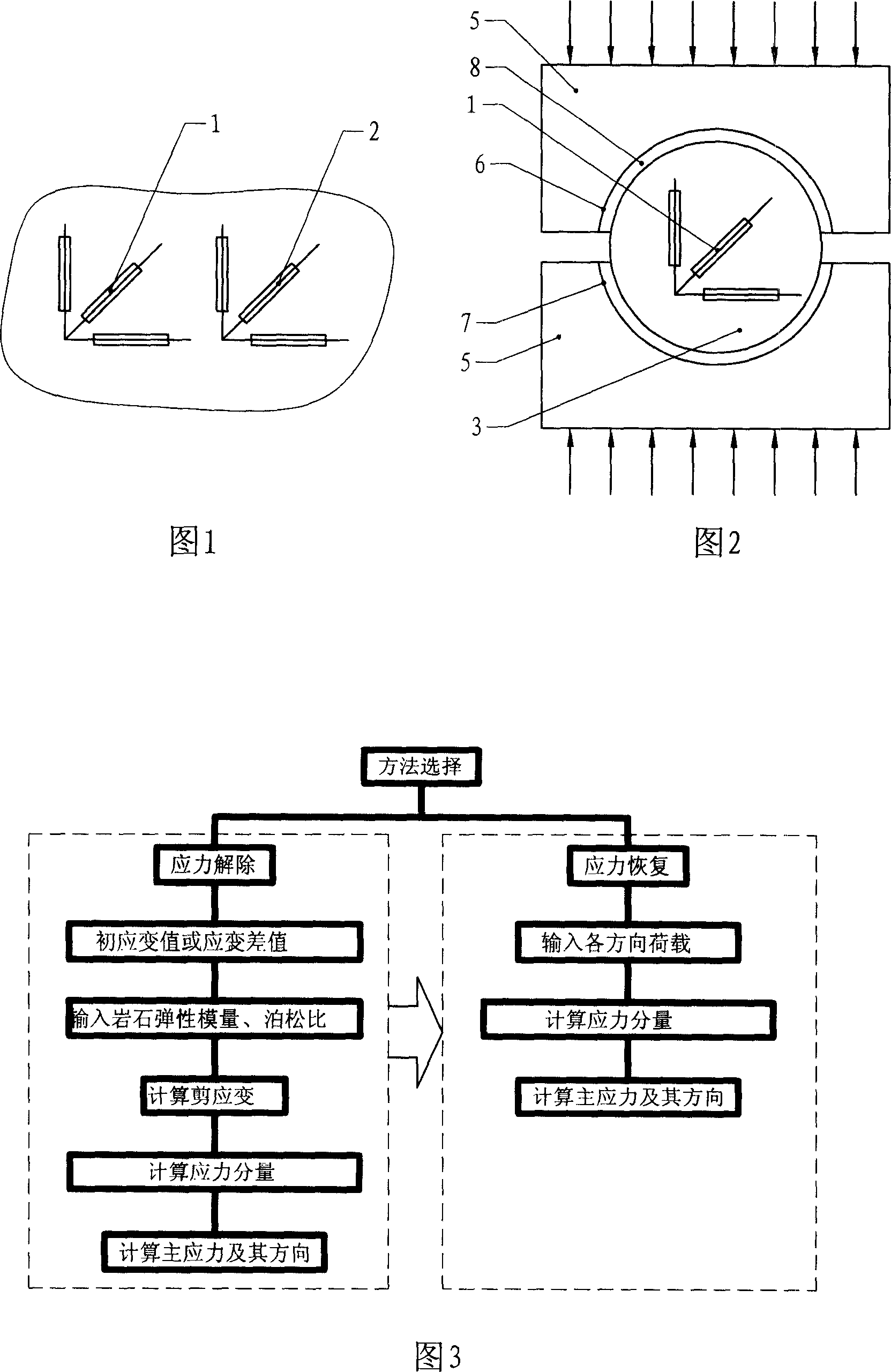

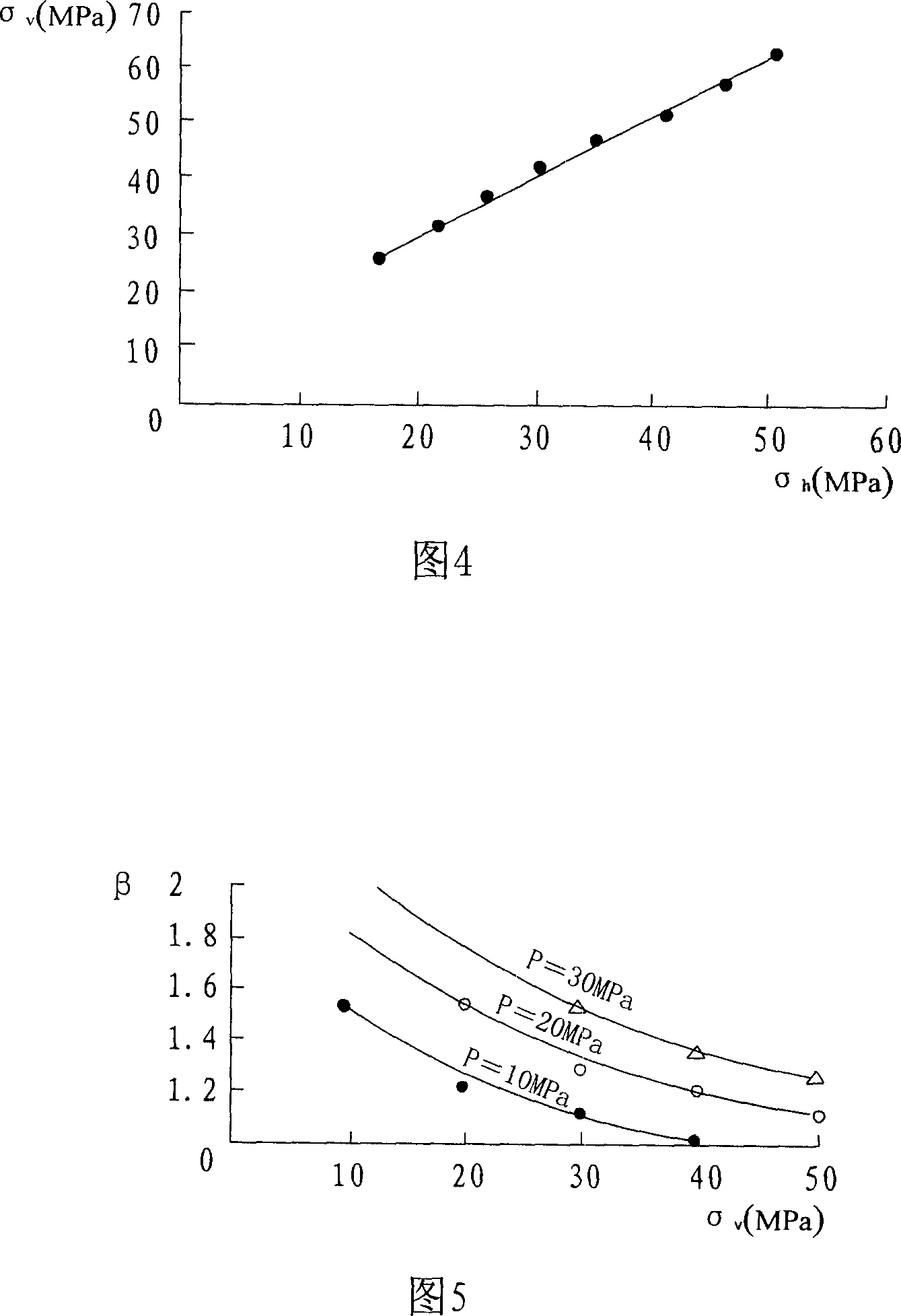

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0033] As shown in Fig. 1 and Fig. 2, the test method of cave wall stress of the present invention is to use the same rock core 3 and the same group of measuring strain rosettes 1 to carry out stress relief measurement and stress recovery measurement, and simultaneously the elasticity of the rock can also be completed as follows: The measurement of elastic modulus E and Poisson's ratio μ can minimize the measurement error. The specific measurement steps are as follows:

[0034] (1) Stress relief method:

[0035]a. On the selected measuring point of the rock on the cave wall, according to the conventional requirements, cut the measuring point flat with a cutting machine, etc., use sandpaper and other tools to polish the surface, and then use a cotton ball dipped in acetone to clean the surface, These are all conventional treatments of rock surfaces when...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com