Hartman wave front sensor to realize alignment function by light splitter and testing method thereof

A spectroscopic device and sensor technology, which is applied in the field of precision instruments and Hartmann wavefront sensors, can solve problems such as the deviation of the measured beam from the optical axis of the system, the increase in the error of wave surface measurement, and the difficulty of adjusting the incident wave front, etc. The effects of measurement accuracy, reduced requirements, and small detection errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] When the Hartmann wavefront sensor is working, the error of the system itself needs to be calibrated first.

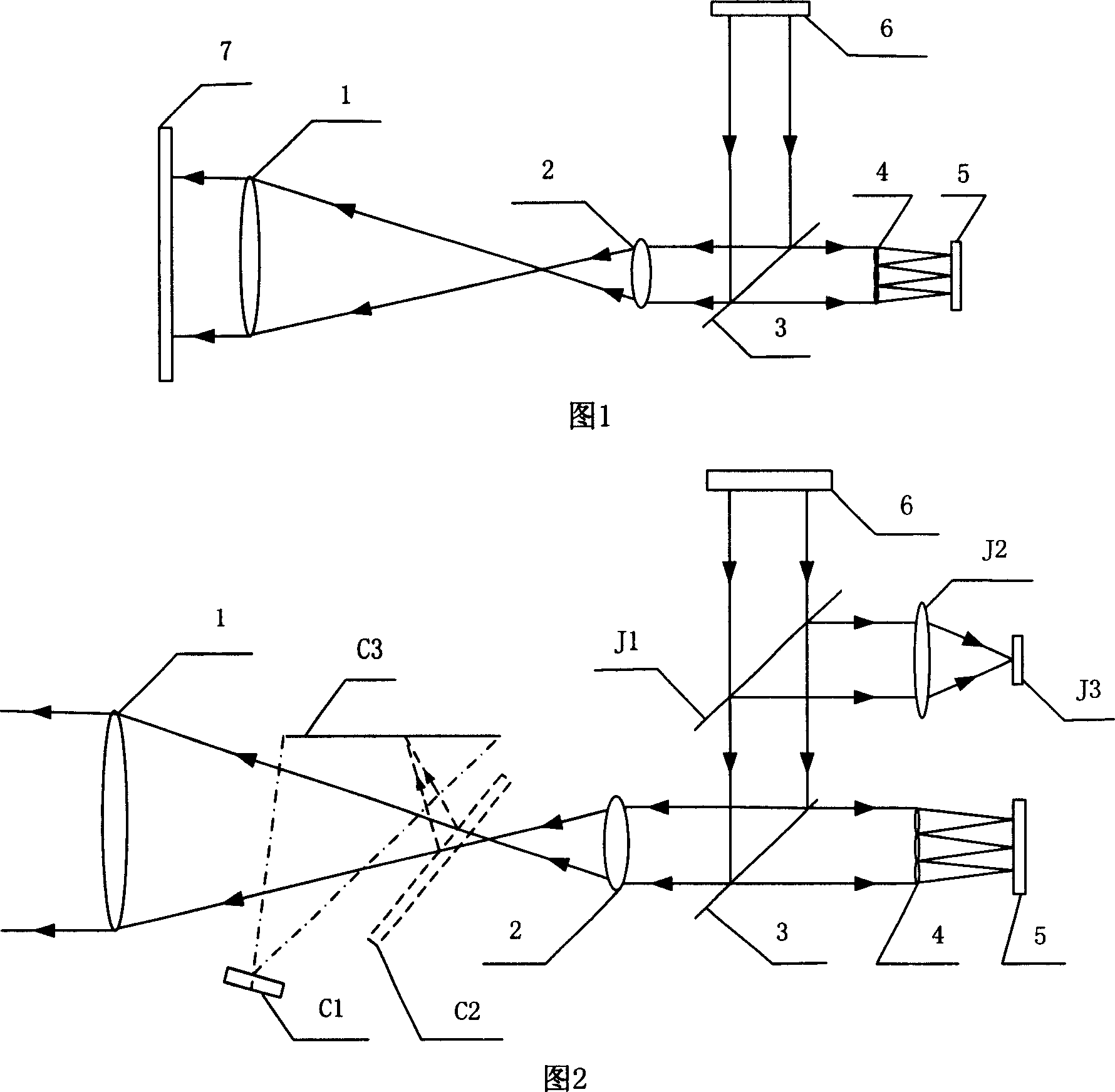

[0018] As shown in Figure 1, when calibrating the system error, the light beam emitted by the measurement light source system 6 first passes through the beam splitter 3, then passes through the front mirror group 1 and rear mirror group 2 of the beam matching system, and finally exits the system. After being reflected by the standard plane mirror 7, it returns to the system, passes through the beam matching system, the beam splitter 3, and the microlens array 4, and forms an image on the photodetector 5. The position of the standard flat mirror 7 is adjusted to finally make the spot arrangement on the photodetector 5 meet the measurement requirements. But the area of microlens array 4 is about 1cm 2 , is very small compared to the overall optical path, resulting in a small adjustable range of the standard plane mirror 7, and the adjustment is very difficult. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com