Method for testing moisture content by sulfonyl isocyanate pre-column derivation method

A sulfonyl isocyanate, pre-column derivatization technology, applied in the field of analytical chemistry, can solve the problems of expensive instruments, difficult to popularize, cumbersome operation, low accuracy, etc., and achieves the effects of fast measurement, low cost, and few side reaction products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

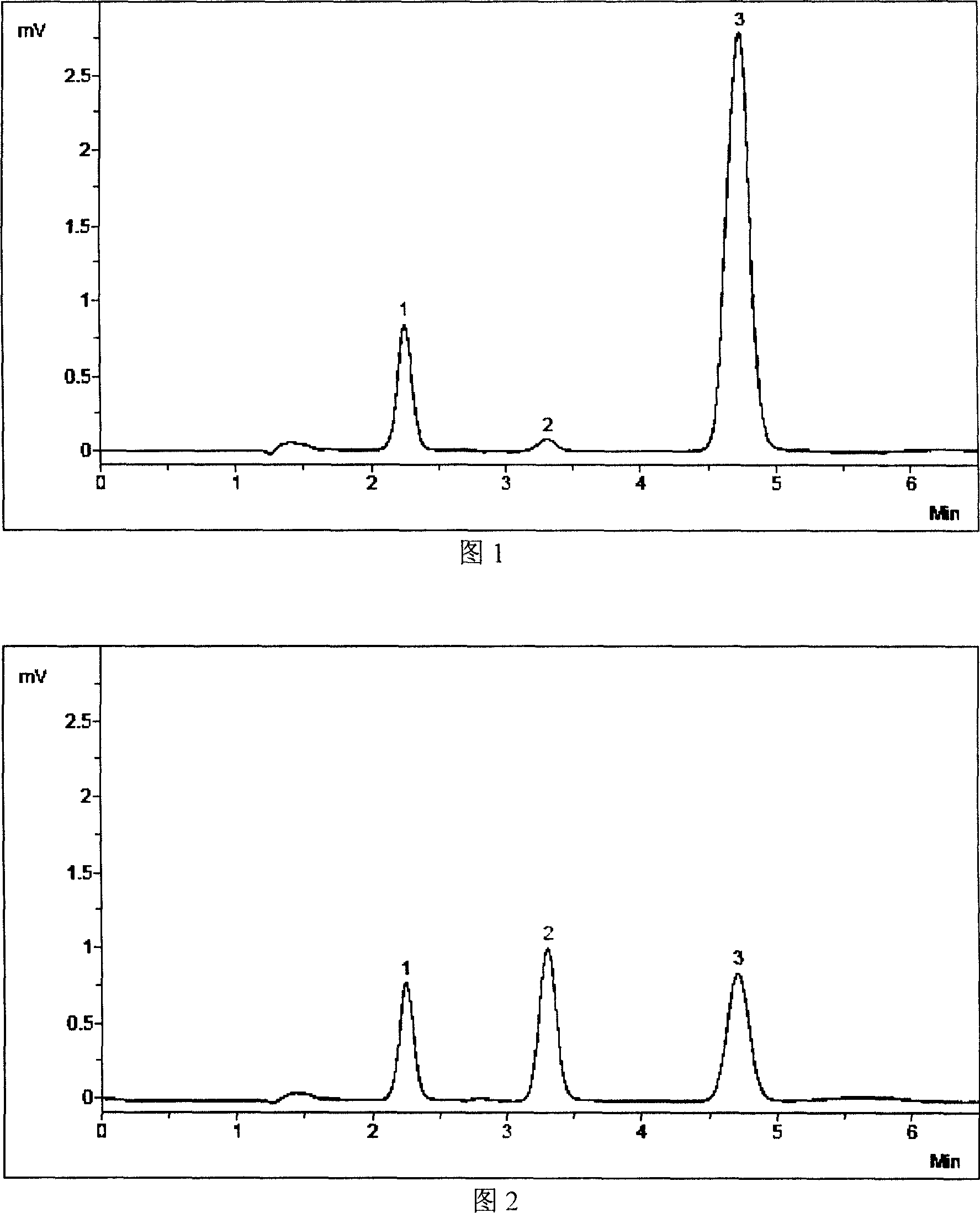

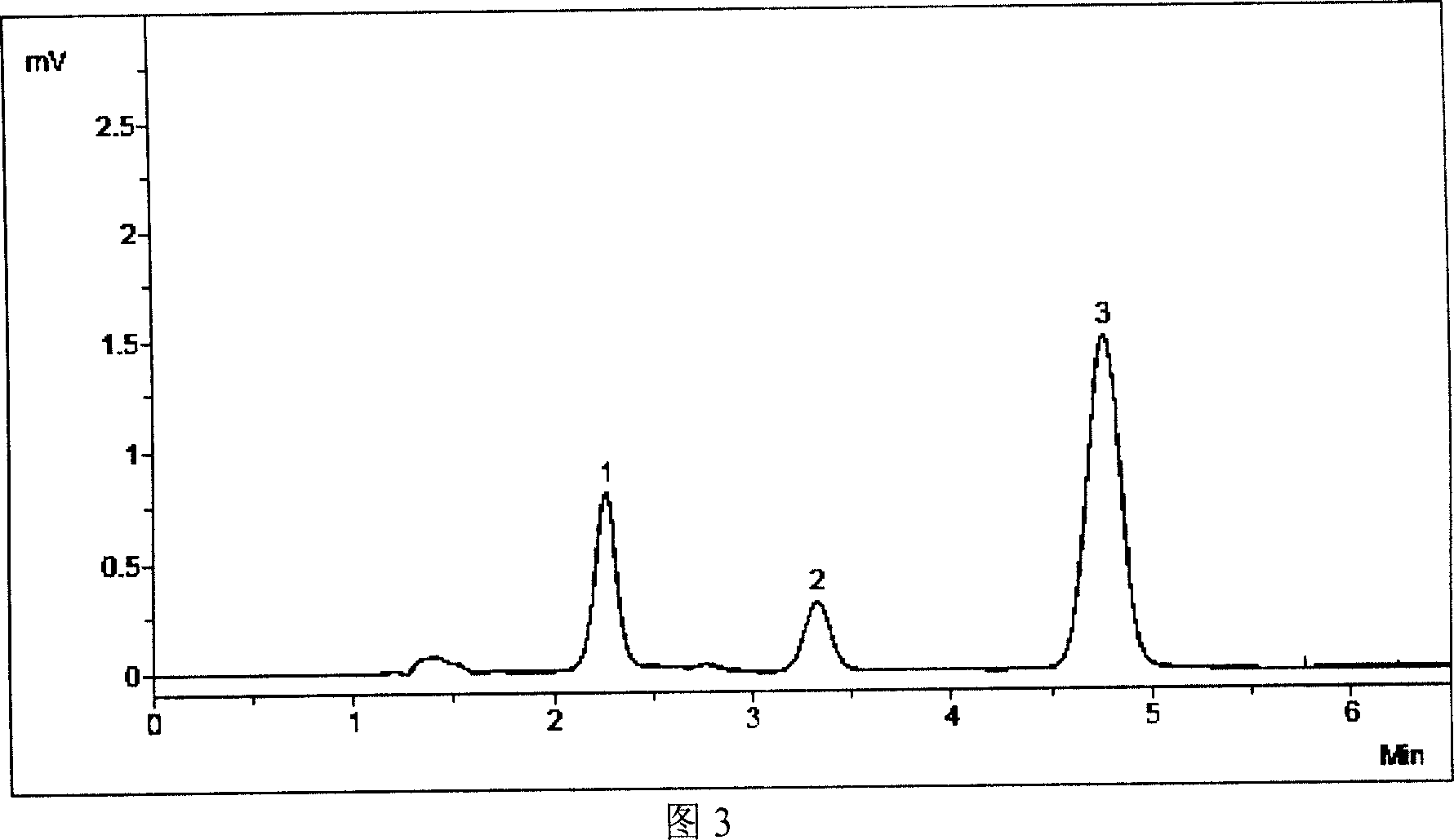

[0024] Instruments and Conditions:

[0025] Japan Shimadzu 10A high performance liquid chromatography system, including binary gradient system, column temperature control box, UV-Vis variable wavelength detector, Hangzhou Yingpu HS2000 workstation and 20μL manual sampling system; chromatographic column: 150×4.6mm ID , 5μm Diamonsil TM C 18 (DIKMA); water phase: weigh 0.69gKH 2 PO 4 Dissolve in 500ml of pure water, and adjust the pH to 2.5 with phosphoric acid. Organic phase: acetonitrile. Equivalent elution, aqueous phase: organic phase = 55:45; flow rate: 1.0 mL / min; column temperature: 25°C; detection wavelength: 227nm; injection volume: 20 μL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com