A nitrogen-doped carbon nanotube modified electrochemical sensor and its application

A technology of nitrogen-doped carbon and nanotubes, applied in the field of sensors, can solve the problems of high instrument requirements, unsuitable sample pretreatment process for high-throughput, real-time on-site screening technology, and expensive analysis costs, etc., to achieve high sensitivity The measurement and production methods are simple and easy, and the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

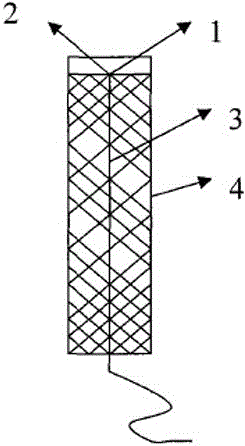

[0030] The preparation method of the working electrode of the electrochemical sensor is as follows:

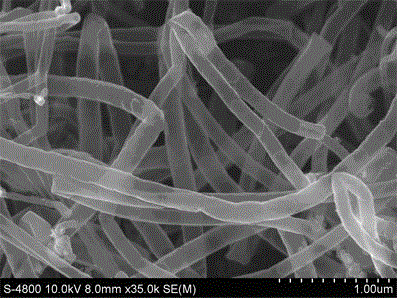

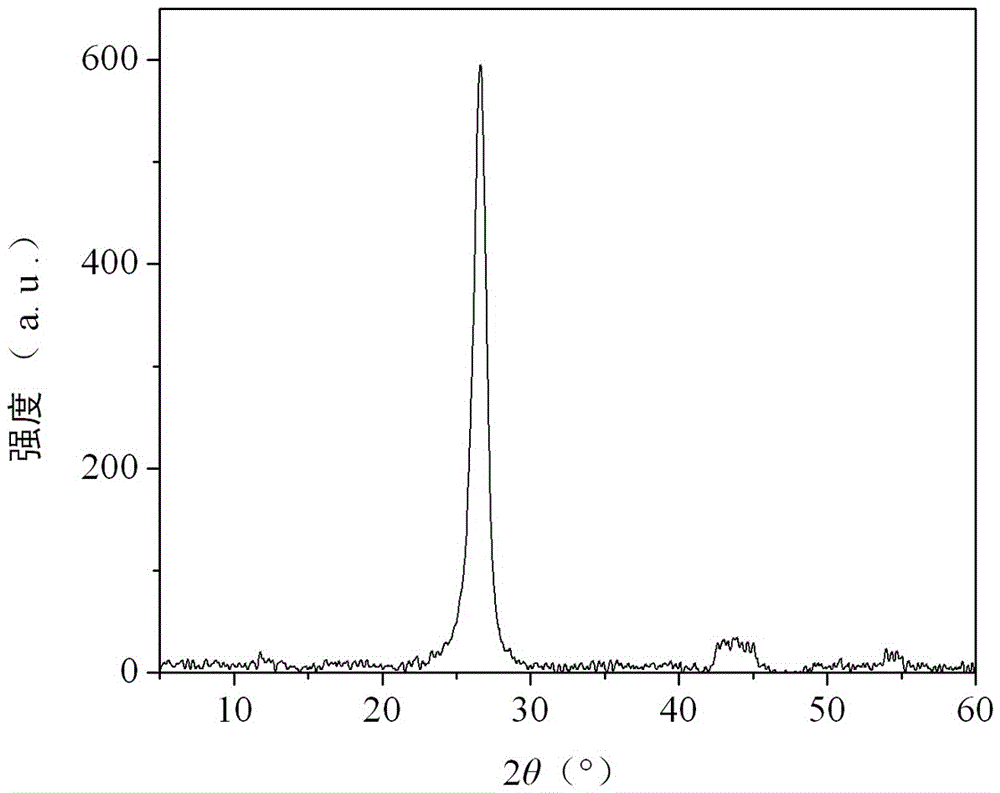

[0031] 1) NiNO 3 After mixing with NaY molecular sieve according to the weight ratio of 1:1, dissolve in distilled water, filter and dry, grind the dried sample and put it into a small porcelain boat, heat it to 1123 K in a quartz tube furnace, and then pass it through at a constant flow rate Into N 2 / diethylamine mixed gas, kept at constant temperature for 3h, cooled naturally, and black CN was obtained x The mixture with Ni / NaY catalyst, after removing the molecular sieve catalyst in HF solution, nitrogen-doped carbon nanotubes can be obtained. figure 2 is the SEM image of the obtained nitrogen-doped carbon nanotubes. image 3 is the XRD pattern of the obtained nitrogen-doped carbon nanotubes.

[0032] 2) Accurately weigh 3 mg of the nitrogen-doped carbon nanotubes obtained above, add to 10 mL of ethanol, and oscillate ultrasonically for 10 min to disperse into a uni...

Embodiment 2

[0037] The preparation method of the working electrode of the electrochemical sensor is as follows:

[0038] 1) NiNO 3 After mixing with NaY molecular sieve according to the weight ratio of 2:1, dissolve with distilled water, filter and dry, grind the dried sample and put it into a small porcelain boat, heat it to 1223 K in a quartz tube furnace, and then pass it through at a constant flow rate Into N 2 / Diethylamine mixed gas, kept at constant temperature for 4 hours, cooled naturally, and black CN was obtained xThe mixture with Ni / NaY catalyst, after removing the molecular sieve catalyst in HF solution, nitrogen-doped carbon nanotubes can be obtained.

[0039] 2) Weigh 5 mg of the nitrogen-doped carbon nanotubes obtained in step (1), add it to 10 mL of ethanol, and oscillate ultrasonically for 20 min to disperse into a uniform black suspension.

[0040] 3) Apply the dispersion liquid described in step (2) onto the surface of the glassy carbon electrode (Φ=3mm), and let it...

Embodiment 3

[0043] The preparation method of the working electrode of the electrochemical sensor is as follows:

[0044] 1) NiNO 3 After mixing with NaY molecular sieve according to the weight ratio of 1:2, dissolve with distilled water, filter and dry, grind the dried sample and put it into a small porcelain boat, heat it to 1023 K in a quartz tube furnace, and then pass it into N 2 / Diethylamine mixed gas, kept at constant temperature for 1h, cooled naturally to obtain black CN x The mixture with Ni / NaY catalyst, after removing the molecular sieve catalyst in HF solution, nitrogen-doped carbon nanotubes can be obtained.

[0045] 2) Stir the nitrogen-doped carbon nanotubes prepared in step (1) in HF solution for 8 hours, remove the molecular sieve catalyst, accurately weigh 2 mg, add it to 10 mL of ethanol, and oscillate ultrasonically for 6 minutes to disperse into a uniform black suspension liquid.

[0046] 3) Apply the dispersion liquid described in step (2) dropwise on the surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com