Single fiber and multi-core fiber coupler and fused biconic taper coupling method thereof

A technology of multi-core optical fiber and single-core optical fiber, applied in the field of optical fiber, can solve the problems of large volume, unsolved coupling between single-core optical fiber and multi-core optical fiber, poor reliability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

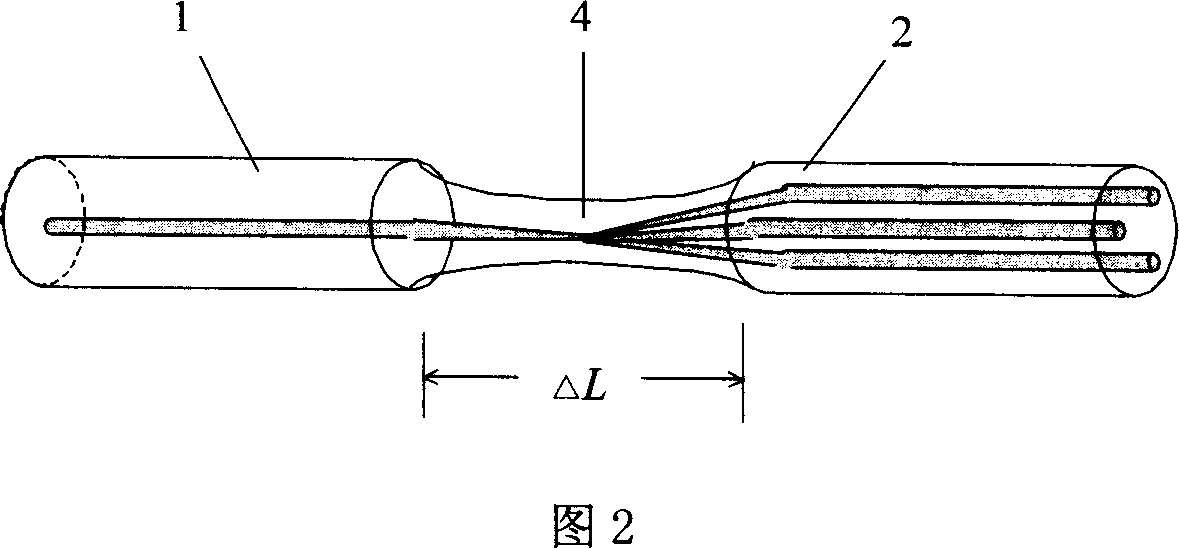

[0026] In this embodiment, the coating layer at one end of a single-core optical fiber and a multi-core optical fiber is stripped off, and after stripping, the end face of the optical fiber is cleaned and cut to form a smooth end face, and then directly fused at the stripped place by an optical fiber welding machine, and welded. Heating at the point to implement melting taper, and monitor the optical power. When the waist of the cone is thinned to the predetermined splitting ratio achieved by the distribution of optical power by the cone, the taper is stopped to make single-core fiber and multi-core fiber coupler. .

[0027] The method of fusion splicing taper coupling is:

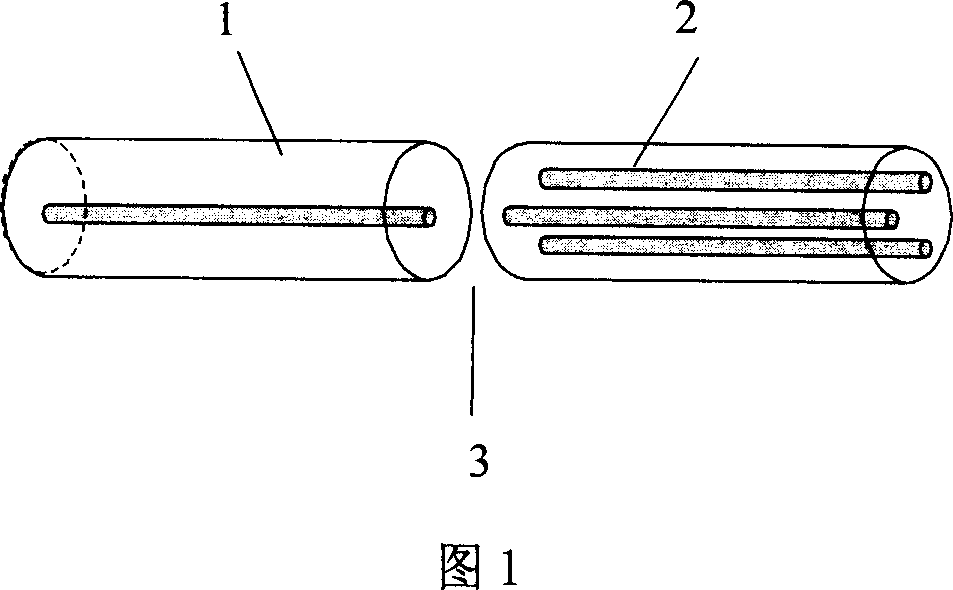

[0028] 1. Select the single-core optical fiber 1 to be coupled, peel off the coating layer at one end, and then clean and cut out a flat fiber end face; 1 is a single-core optical fiber, 2 is a multi-core optical fiber, and 3 is two sections of optical fiber for welding Join the ends.

[0029] 2. Prepare...

Embodiment 2

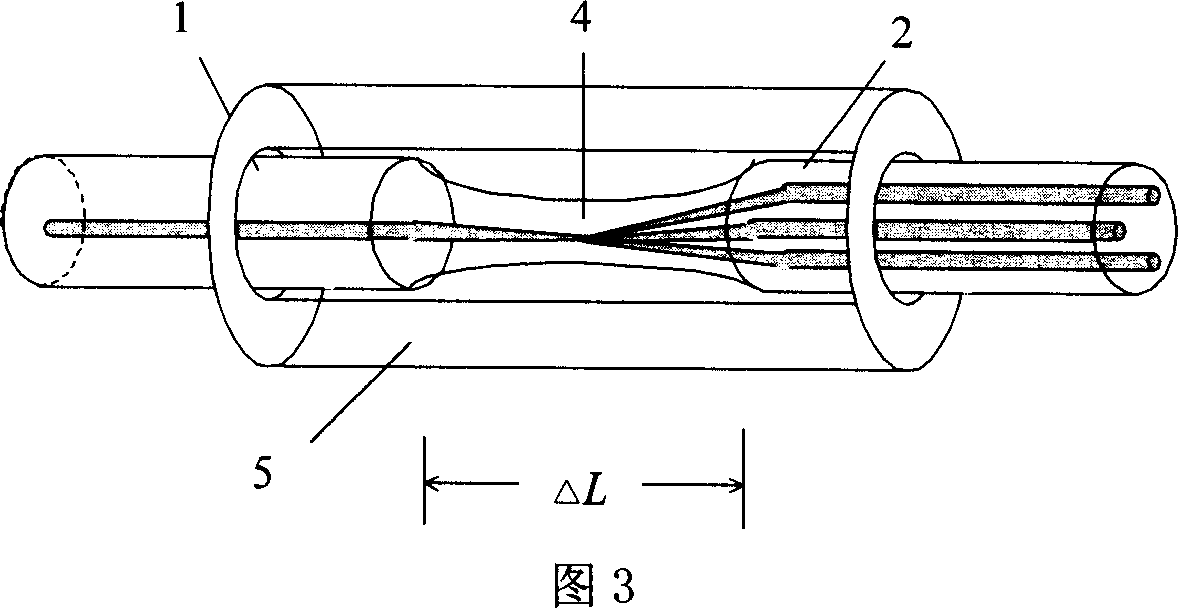

[0036] In this embodiment, the coating layer at one end of a single-core optical fiber and a multi-core optical fiber is stripped off, and after stripping, the end face of the optical fiber is cleaned and cut to form a smooth end face, and then directly fused at the stripped place by an optical fiber welding machine, and welded. Heating at the point to implement melting taper, and monitor the optical power. When the waist of the cone is thinned to the predetermined splitting ratio achieved by the distribution of optical power by the cone, the taper is stopped to make single-core fiber and multi-core fiber coupler. .

[0037] The method of fusion splicing taper coupling is:

[0038] 1. Select the single-core optical fiber 1 to be coupled, peel off the coating layer at one end, and then clean and cut out a flat fiber end face; 1 is a single-core optical fiber, 2 is a multi-core optical fiber, and 3 is two sections of optical fiber for welding Join the ends.

[0039] 2. Prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com