Organic EL display device

A display device and organic technology, which is applied to lighting devices, electrical components, circuits, etc., can solve the problems of organic light-emitting media destroying display, prone to disconnection, and increasing cost, and achieves improved fluorescence conversion efficiency, reduced defects, and simplified structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

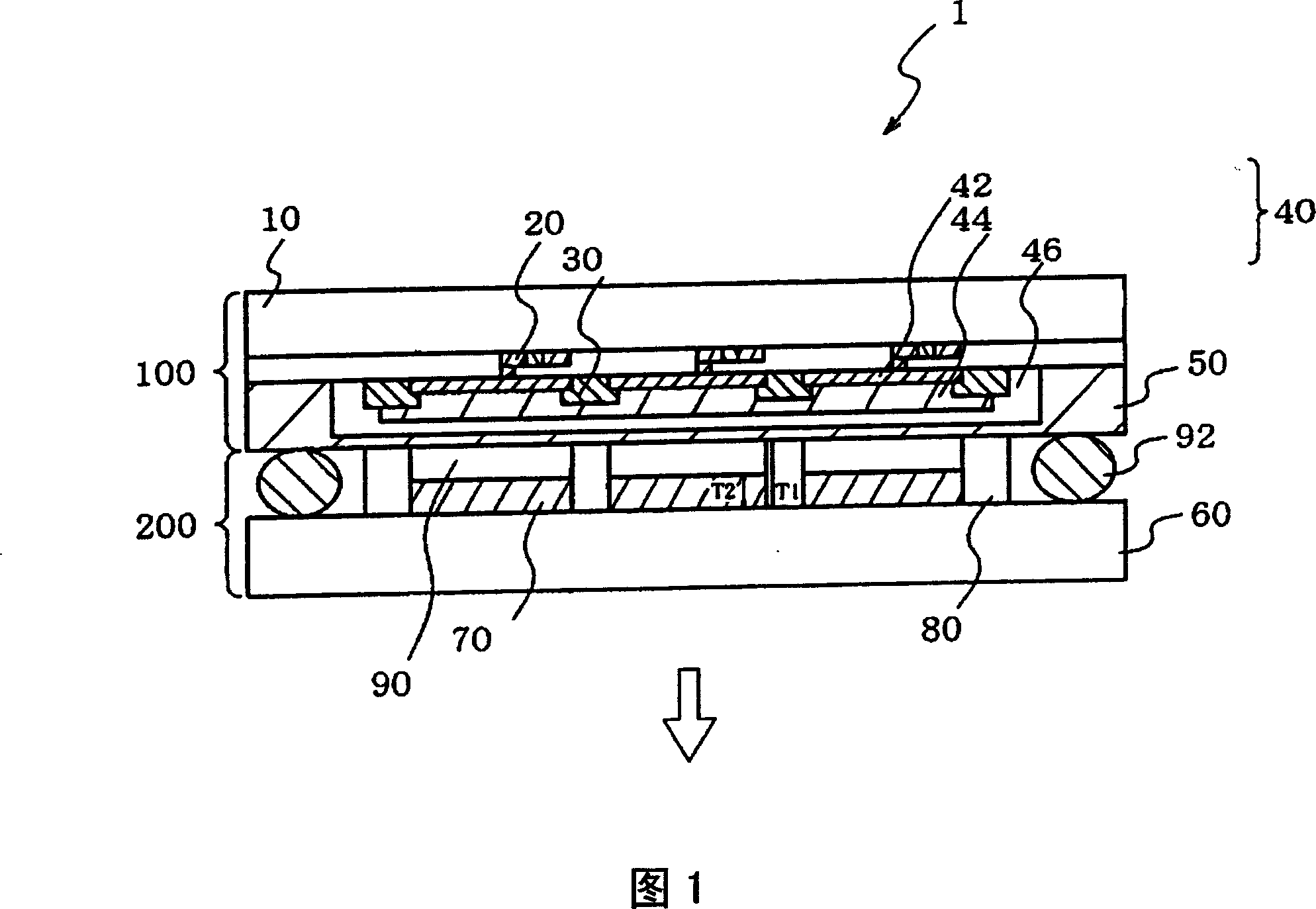

[0060] FIG. 1 shows an organic EL display device according to one embodiment of the present invention.

[0061] This organic EL display device 1 comprises an organic EL substrate 100 on which an organic EL element 40 is formed on a first substrate 10, and a color conversion substrate 200 on which a color conversion layer 70 is formed on a second substrate 60 so that the organic EL element 40 and the color The transformation layers 70 are arranged so as to face each other.

[0062] Specifically, in the organic EL substrate 100 , the TFT 20 , the interlayer insulating film 30 , the lower electrode 42 , the organic luminescent medium 44 , the upper electrode 46 , and the barrier film 50 are formed on the first substrate 10 . Here, the organic EL element 40 is constituted by the lower electrode 42 , the organic light-emitting medium 44 , and the upper electrode 46 .

[0063] In the color conversion substrate 200 , the color conversion layer 70 and the transparent partition walls ...

Embodiment approach 2

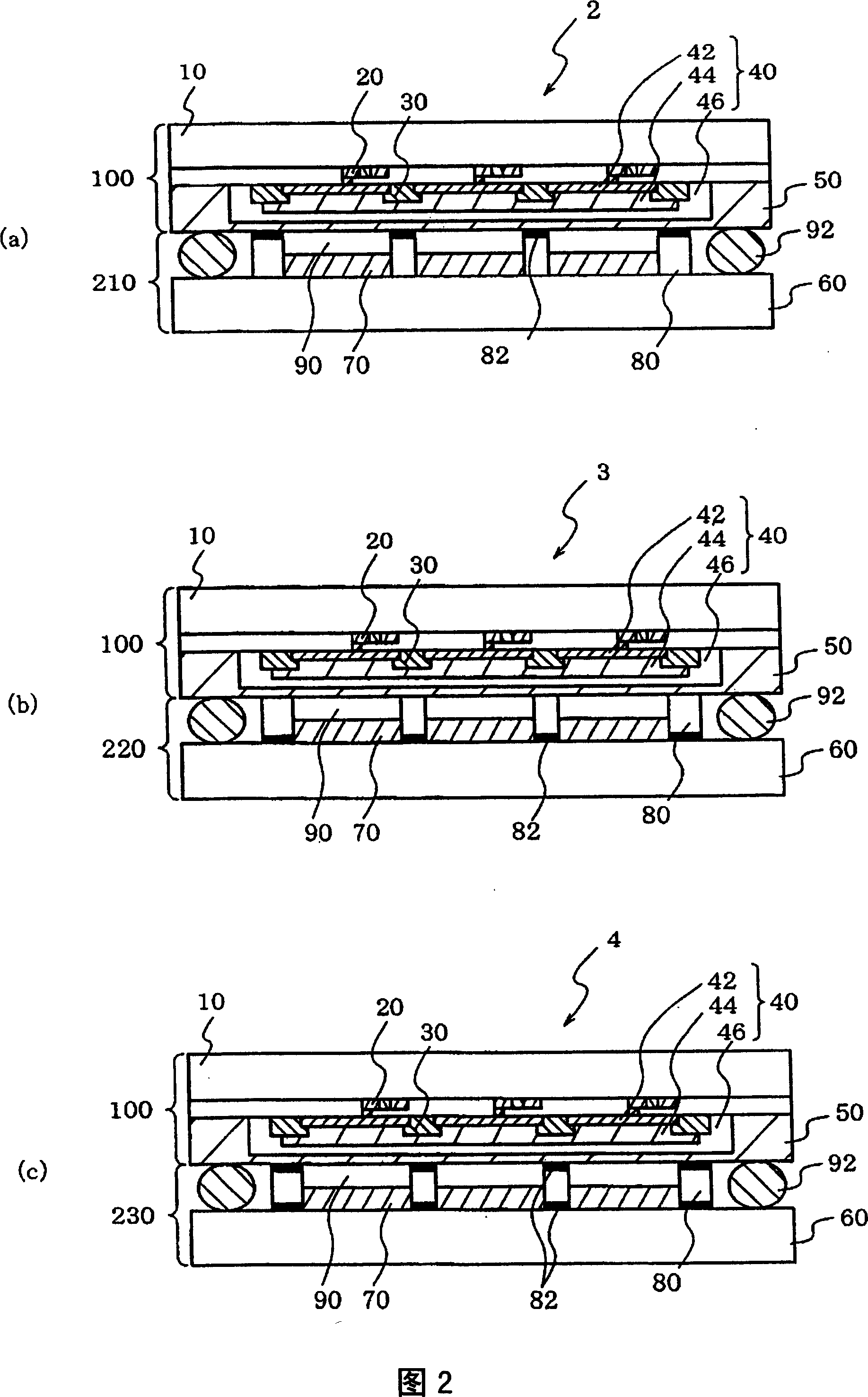

[0075] FIG. 2 shows an organic EL display device according to another embodiment of the present invention.

[0076] In addition, in the following drawings, the same reference numerals are used for the same members as those in FIG. 1 , and description thereof will be omitted.

[0077] In this embodiment, only the partition wall of the color conversion substrate is different from the first embodiment.

[0078] In the organic EL display device 2 of FIG. 2( a ), a light shielding layer 82 is formed on the upper portion of the partition wall 80 of the color conversion substrate 210 .

[0079] In the organic EL display device 3 of FIG. 2( b ), a light shielding layer 82 is formed on the lower portion of the partition wall 80 of the color conversion substrate 220 .

[0080] In the organic EL display device 4 of FIG. 2( c ), light shielding layers 82 are formed on the lower and upper portions of the partition walls 80 of the color conversion substrate 230 .

[0081] By forming the l...

Embodiment approach 3

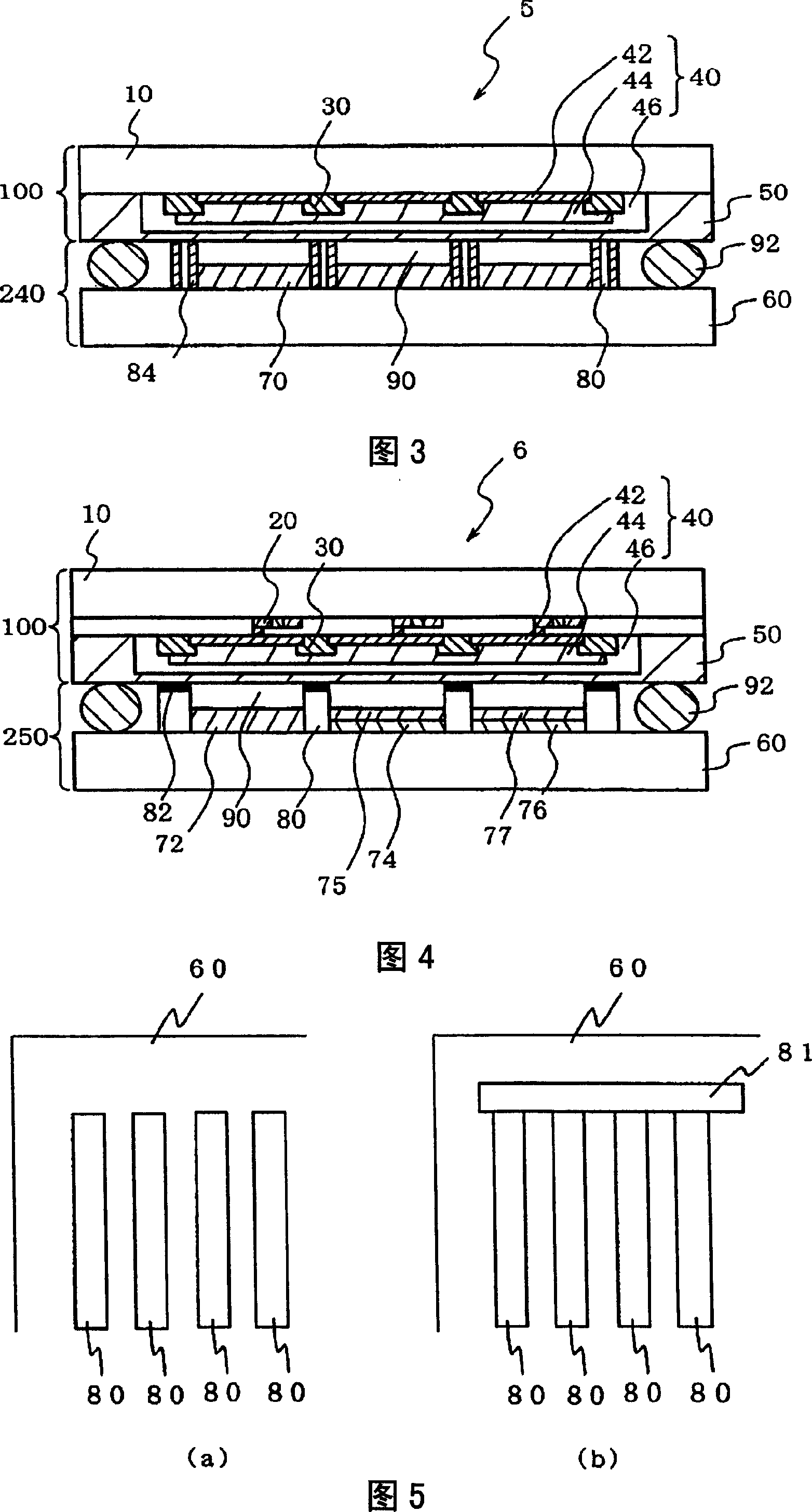

[0083] FIG. 3 shows an organic EL display device according to another embodiment of the present invention.

[0084] In this embodiment, only the partition wall of the color conversion substrate is different from the first embodiment.

[0085] In the organic EL display device 5 of FIG. 3 , a reflective layer 84 having a function of reflecting visible light is formed on the side of the partition wall 80 of the color conversion substrate 240 .

[0086] The light emitted from the color conversion layer 70 is reflected by the reflective layer 84 and is effectively used for display of the organic EL display device. Moreover, in order to reflect visible light not only with the reflective layer but also with the side walls of the partition walls, the side surfaces may be roughened, and particles having a refractive index different from those of the partition walls may be dispersed in the partition walls to the extent that the transparency of the partition walls is not lost to scatter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com