Composite metal tile and its making process

A composite metal and manufacturing method technology, applied in the direction of chemical instruments and methods, lamination auxiliary operations, synthetic resin layered products, etc., can solve problems such as poor economy, dew condensation, and complicated construction, and achieve heat preservation, dew condensation and high temperature resistance , solve the noise, reduce the effect of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings and other preferred examples.

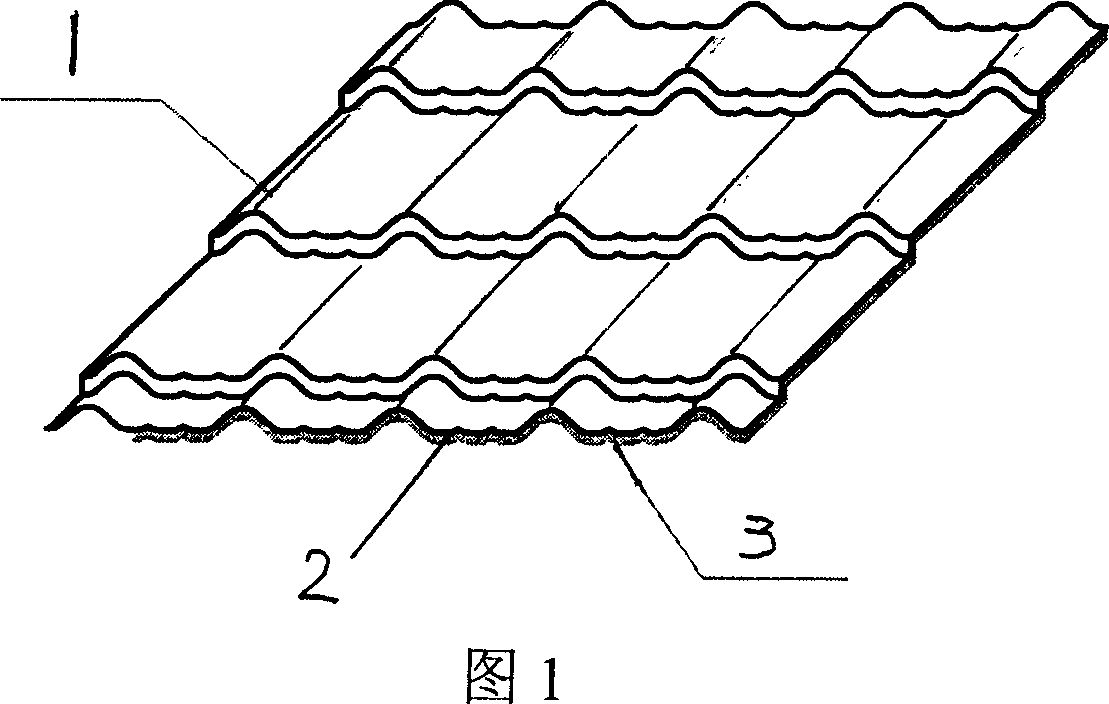

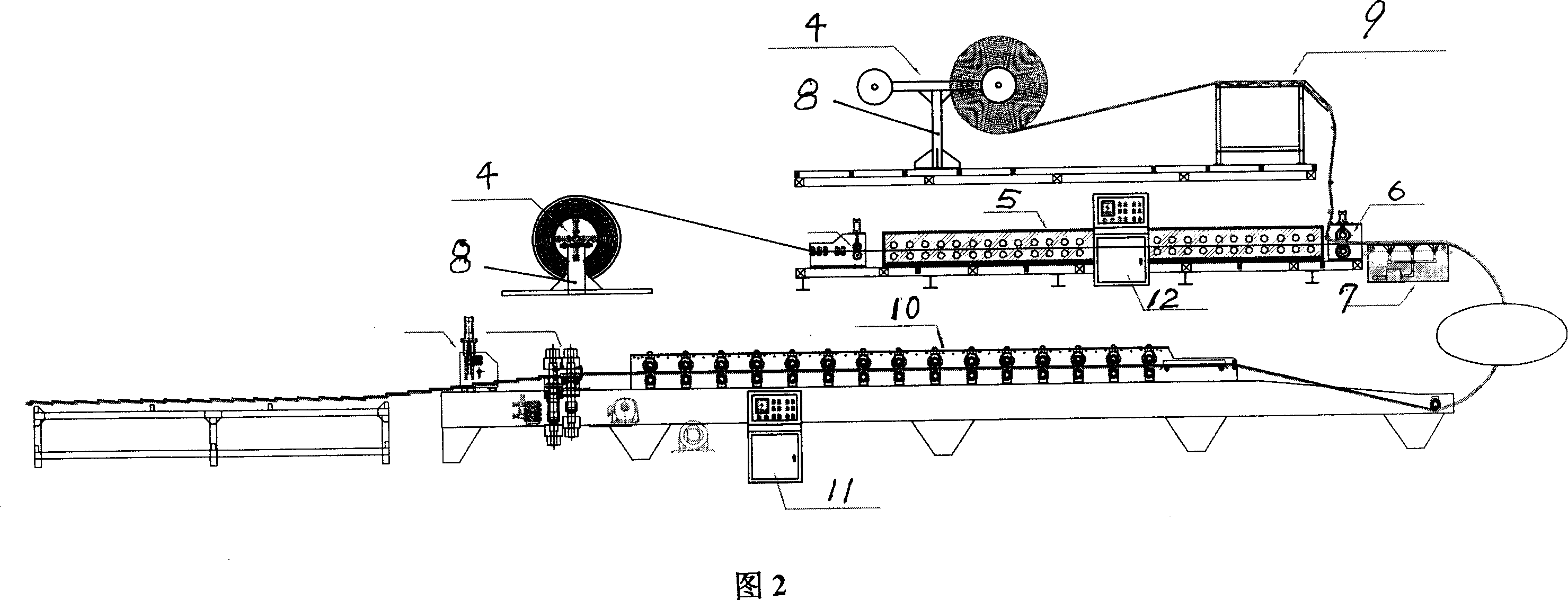

[0022] Referring to the accompanying drawings, a composite metal tile includes a colored metal or non-metallic plate, a primer layer 2 is provided on the back of the colored metal or non-metallic plate 1 and a polyethylene foam plate 3 is thermally welded, and the metal plate is The material used is color-plated plate, copper plate, aluminum plate, stainless steel plate, aluminum-zinc alloy plate, non-metallic plate is made of plastic material, and its thickness is 0.2mm-1mm; ~1150mm. The processing equipment of the composite metal tile is composed of an uncoiler 4, an electric heating furnace 5, a laminating roll 6, a cooling device 7, a bracket 8, a supply device 9, a metal tile forming machine 10, a forming machine controller 11, an electric furnace controller 12, etc. A set of continuous automatic production...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com